Global Simmerring® Engineering Services

Unlock Optimal Sealing Performance with Our Radial Shaft Seal Engineering Services

For engineers seeking precision in sealing solutions, look no further than Freudenberg Sealing Technologies. Our specialized services are meticulously crafted with Simmerring® in mind, offering an unmatched level of expertise that extends beyond the mere selection of top-tier sealing components.

Our approach is rooted in engineering excellence. We recognize that achieving the perfect sealing solution for your application demands more than just individual component quality. Our seasoned experts adopt a holistic perspective, meticulously analyzing the intricate interplay of all system components to unlock the optimal sealing performance.

When precision and engineering ingenuity matter most, trust Freudenberg Sealing Technologies to elevate your sealing systems to a new level of excellence.

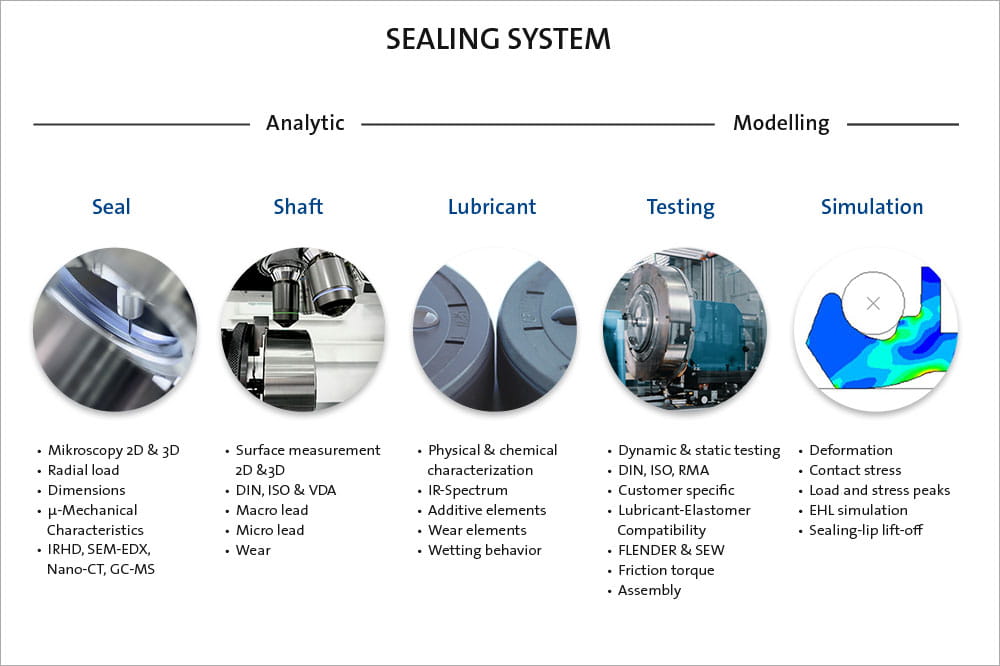

The radial shaft sealing system represents a highly intricate tribological ecosystem, where its functionality and operational longevity are intricately intertwined with a multitude of factors. These factors encompass the intricate dynamics among the constituent system elements, namely the radial shaft seal, the shaft itself, and the lubricating agent, as well as the diverse and demanding operating conditions specific to each unique application.

Our Simmerring® Engineering experts depend on thorough analysis and detailed characterization techniques applied to the system components. Additionally, they employ precise inspection and rigorous testing procedures tailored to the tribological system's complexities. These methods serve as the key to unraveling the answers to crucial questions, such as:

-

What is the optimal design of the sealing system for this particular application?

-

What led to a failure or leakage in this specific case?

Harnessing Precision and Innovation for Sealing System Excellence

Achieving peak performance and prolonged service life in a sealing system hinges upon the meticulous alignment of its core components: the radial shaft seal, the shaft, and the lubricant. This alignment is our unwavering focus. Our investigations delve deep into the comprehensive analysis of the entire tribological system.

With cutting-edge testing and measurement technology, we employ standardized and innovative analysis and evaluation procedures. These methodologies enable us to provide detailed insights into the condition of every facet within the sealing system.

From these analytical results, our experts formulate hypotheses regarding potential failure causes. These hypotheses are then rigorously tested, either through physical testing or simulations, to validate their accuracy. The culmination of these efforts yields profound insights, leading to concrete recommendations for optimization.

The ultimate goal: enhancing sealing functionality and significantly extending the service life of your sealing system.

Simmerring® Engineering Support Across the Globe

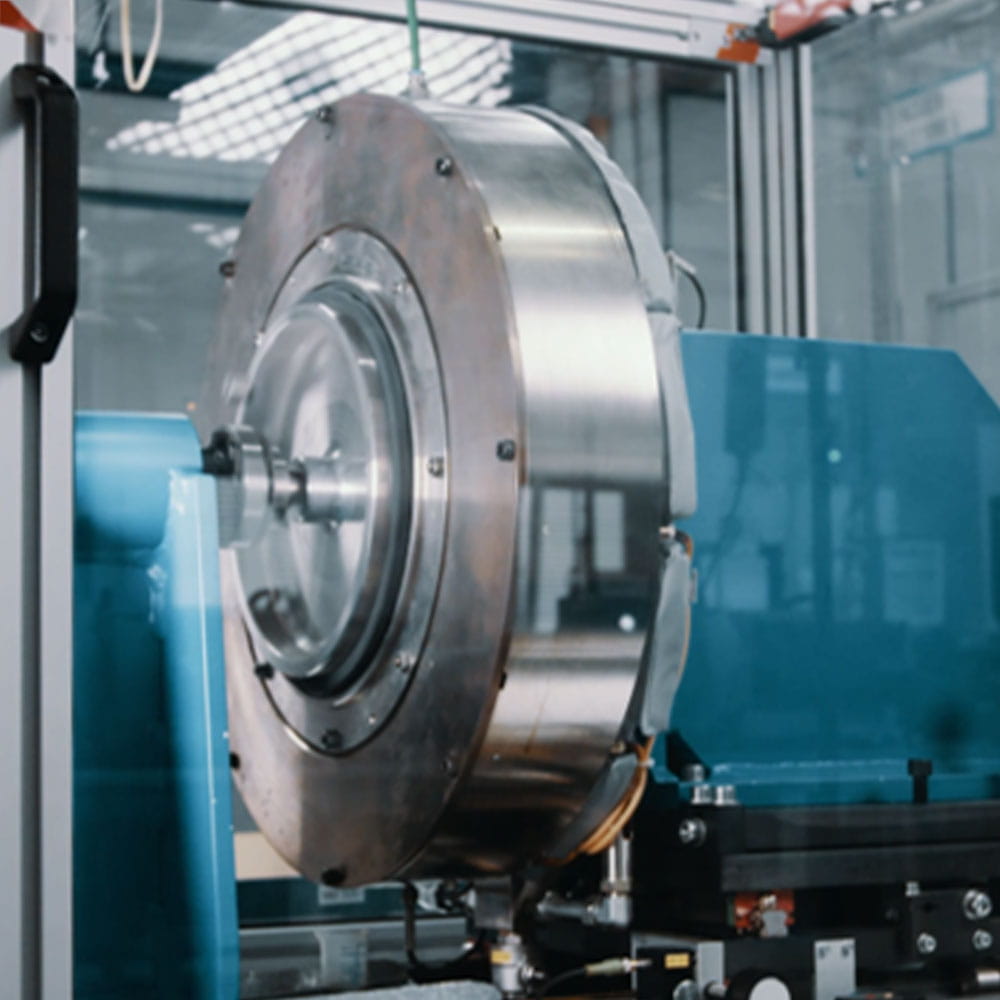

Our commitment to serving customers globally knows no bounds. With access to extensive testing and validation capacities, our customers can benefit from customized tests, available on demand. You'll find these cutting-edge facilities at the world's largest test facility for dynamic seals in Weinheim, Germany, and our state-of-the-art test center in Ashland, New Hampshire, USA. With over 300 test stands available, you can rely on our global network to provide the testing and validation solutions you need, no matter where you are in the world."

Tailored Simmerring® Services Available

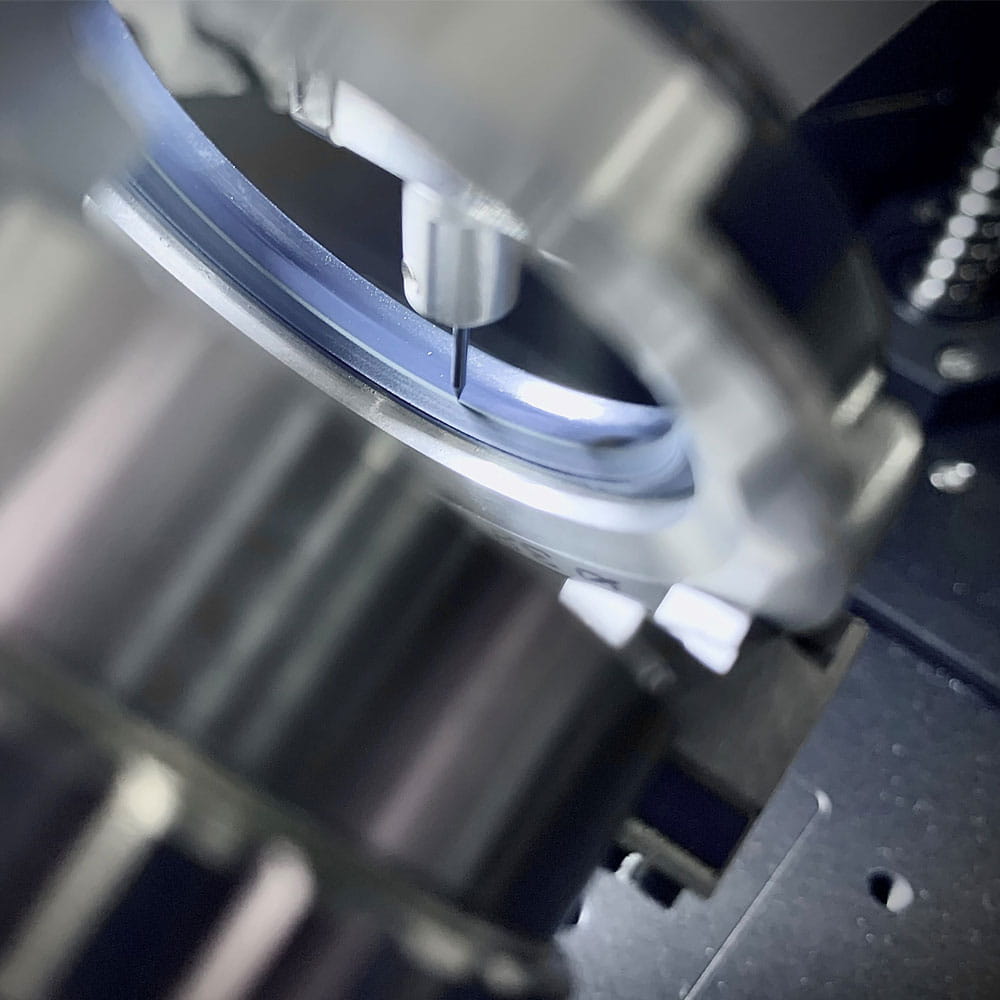

Characterization of the Radial Shaft Seal

A detailed examination of the seal provides information on its condition. For this purpose, optical, chemical as well as micro- and macromechanical changes (e.g. wear, hardening, etc.) are determined and evaluated. The goal is to obtain information on possible damage mechanisms and their causes by analyzing the condition of the seal.

Investigation methods:

- Microscopic assessment of the seal condition

- Measurements of dimensions and sealing characteristics

- Measurement of the International Rubber Hardness Degree (IRHD) according to DIN EN ISO 48

- Mechanical µ-characteristic (microindentor)

- Scanning Electron Microscopy & Energy Dispersive X-ray Spectroscopy (SEM-EDX)

- Nano computed tomography (Nano CT)

- Gas chromatography-mass spectrometry (GC-MS)

- Infrared spectroscopy (IR)

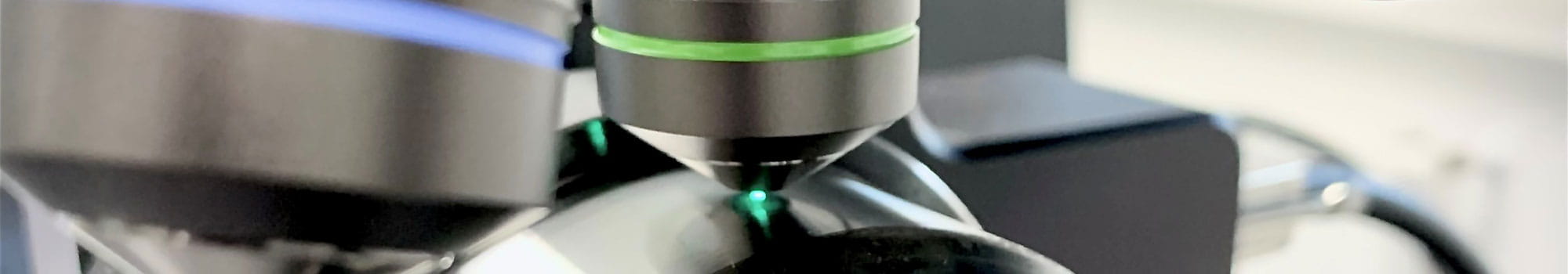

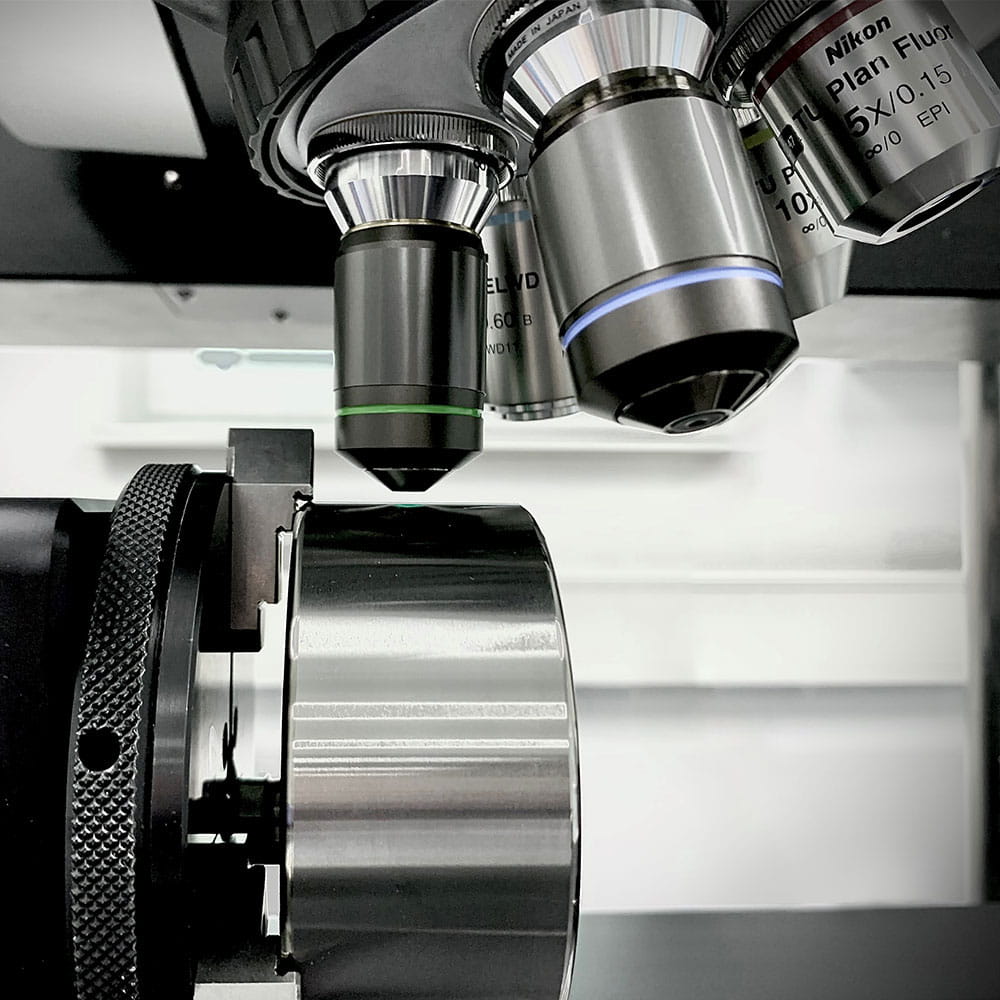

Characterization of the Shaft

The reliable function of a radial shaft sealing system depends to a large extent on the seal counter surface – the shaft. In addition to the appropriate shaft diameter, roundness and hardness of the shaft surface, the microscopic properties of the topography of the seal counter surface are of particular importance.

Investigation methods:

- Tactile and optical measurement of surface parameters of waviness and roughness, according to DIN EN ISO 4287 and DIN EN ISO 25178 as well as VDA, for example

- Qualitative and quantitative macro- and micro lead analysis according to MBN 31 007-7 and IMA Micro Lead®.

- Wear investigation

- Evaluation and suitability assessment of the seal counter surface

- Chemical analysis of deposits on the shaft surface

Characterization of the Fluid

The lubricant plays an important role in the optimal functioning of a radial shaft sealing system. The interactions between the sealing material and the respective lubricant in a specific application must be closely examined. Analysis of the condition with regard to appearance, viscosity, aging, and its chemical composition provides important information on possible interaction mechanisms.

Investigation methods:

- Physical and chemical characterization

- Infrared spectroscopy (identity, additive degradation, oxidation, tramp oils, opacification).

- Analysis of additives in ppm (Ba, Ca, Mg, Cl, Sb, P, Zn, S, Na, Si, K)

- Analysis of abrasion elements in ppm (Al, Cr, Cu, Fe, Pb, Sn, Mo, Ni, Ti, Ag, Mn, V)

- Checking the wetting behavior

Application-Oriented Answers Through Functional Tests and Simulation

The greatest possible insight into the performance of a sealing system is gained through functional testing under the most realistic possible application conditions. Freudenberg Sealing Technologies’ Engineering Service Centers have state-of-the-art dynamic test benches at their disposal to simulate operating conditions as close to reality as possible by means of a wide range of test cycles that can be customized. This allows the entire range of complex tests and validations to be carried out efficiently for all areas of application of radial shaft seals. Furthermore, standardized test procedures allow for reliable assessment of lubricant-elastomer compatibility. Thanks to the use of various simulation methods, the possible behavior of the sealing system in the intended application can be evaluated. For example, FEA (finite element analysis) simulation is used to predict the mechanical behavior of the seal. In addition, specifically developed calculation and simulation methods provide answers to questions concerning functionally relevant parameters of the radial shaft seal.

Functional tests:

- Design and customer validation according to DIN, ISO, RMA or customer specification

- Lubricant-elastomer compatibility according to FLENDER and SEW or customer specification

- Component comparison

- Friction torque measurement

- Assembly force measurement

Testing according to specification

- DIN 51517-3

- DIN 3761

- SEW 971180x15

- ZF

Custom testing and design validation with

- high speeds up to 36,000 rpm

- high pressure up to 15 bar

- high and low angle reciprocating shaft movements (robotics) ±720° with 0.1 ... 5Hz (±720° @ max. 2Hz)

- low temperature up to -50 °C

- contamination by dust and muddy water

- hydraulic motors

Simulation:

- FEA deformation, contact stress, load and voltage peaks

- EHL simulation

- Contact temperature determination

- Lift-off speed analysis

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!