Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

eCON

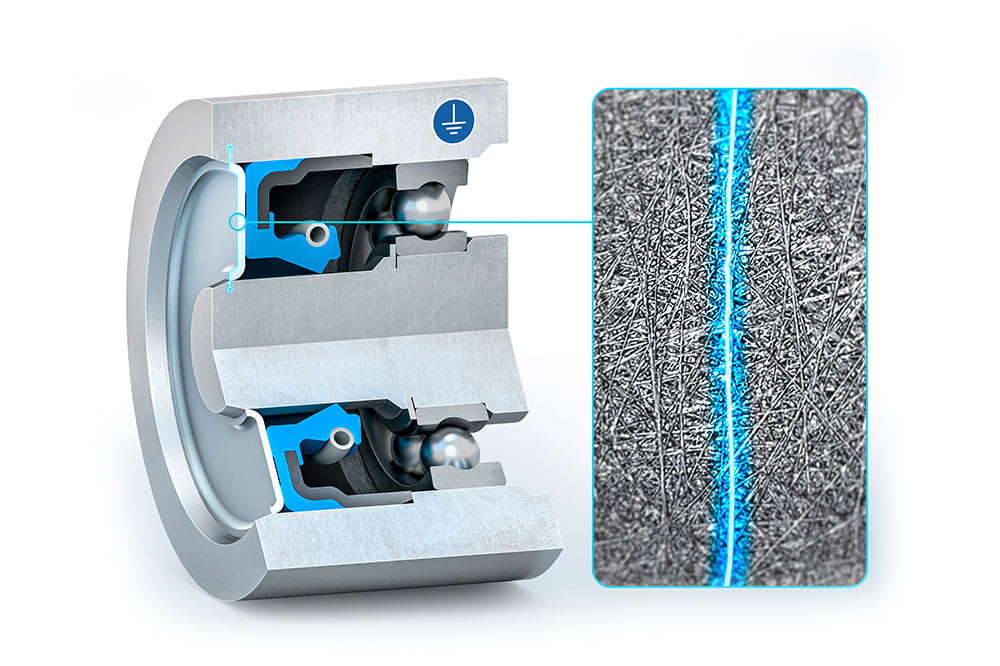

eCON – Electrically Conductive Nonwoven Component for Safe Grounding

Use eCON to Avoid Bearing Damage in Electric Motors

Damaged bearings are a common problem in powerful electric motors. Due to bearing currents and the accompanying electrical erosion, these damages lead to increased noise, vibrations and, in extreme cases, failure of the rolling bearings. eCON, the electrically conductive nonwoven component from Freudenberg, diverts these currents away from the bearing, thus helping to extend its service life.

Freudenberg offers three variants of its grounding system: exclusively as a grounding system (eCON pure), in combination with a friction-optimized Low-Friction Simmerring® (eCON LFS) or combined with a gas-lubricated mechanical seal (eCON LEVITEX).

eCON – for Longer-Lasting Motor Bearings

In eCON pure, eCON LFS and eCON Levitex, Freudenberg combines its material and process expertise to achieve high conductivity and – if needed – reliable sealing. This approach has been successfully established in the market since 2015, for example in the mass production of Europe’s top-selling electric car, the Renault Zoe. The advantages of the eCON are evident in more than just electromobility – industrial motors also benefit from the maintenance-free extension of service life.

All Benefits at a Glance

- extended service life of the motor bearings due to precise discharge of harmful bearing currents

- choice between pure grounding element or a space- and weight-neutral sealing solution with integrated grounding

- does not require any special surface treatment of the shaft and bore

- low-friction and maintenance-free

- less potential interference signals in BUS systems and the AM frequency band

High-Performance Electric Motors Strain Rolling Bearings

The development of increasingly powerful electric motors also poses new challenges for powertrain components. The higher voltages and switching frequencies of the frequency converters generate electrical potential between the rotor and stator of the powertrain. The motor bearings provide the easiest path for the current from the shaft to the housing. In operation, however, this is where an electrically insulating lubricating film is formed, thus creating higher electrical resistance within the bearing. This higher resistance leads to higher electrical potential that dissipates in local discharges, which damage the contact surfaces of the rolling elements in turn.

These discharges lead to:

- massive and irreversible damage of the surfaces in the rolling bearing due to electro-erosion

- noise generation due to vibration

Your Choice: eCON pure or eCON LFS

eCON pure – Safely grounded

eCON pure consists of an electrically conductive nonwoven fabric applied to a metal carrier. The grounding element can be adapted to the installation space as needed.

eCON LFS – Space- and weight-neutral combination

The combination of electrically conductive nonwoven fabric with the proven Low-Friction Simmerring® offers more than just a reliable seal of the rotor shaft, it also ensures safe grounding of the system without adding to the installation space.

Problem-Solving Combination

Avoid discharges in the bearing – Grounding improves durability

By connecting the shaft and housing, eCON creates an electrically conductive connection that bypasses the bearings. This significantly increases the service life of the bearings.

Minimize electromagnetic interferences – Shield against noise

The electrically conductive nonwoven material shields the entire system, thus reducing electromagnetic interferences that trigger noise in the AM frequency range. It also minimizes faulty data transmissions within the BUS system, which ensures that the individual control units can communicate without disturbance.

Protect the whole system – Don’t just bear the problem – solve it

By diverting the current past the motor bearing, eCON prevents local discharges from destroying the bearings. This problem won’t be solved by using insulated bearings, which merely shifts the damage to other components, such as the gearing.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new