Freudenberg Materials - Your Advantage

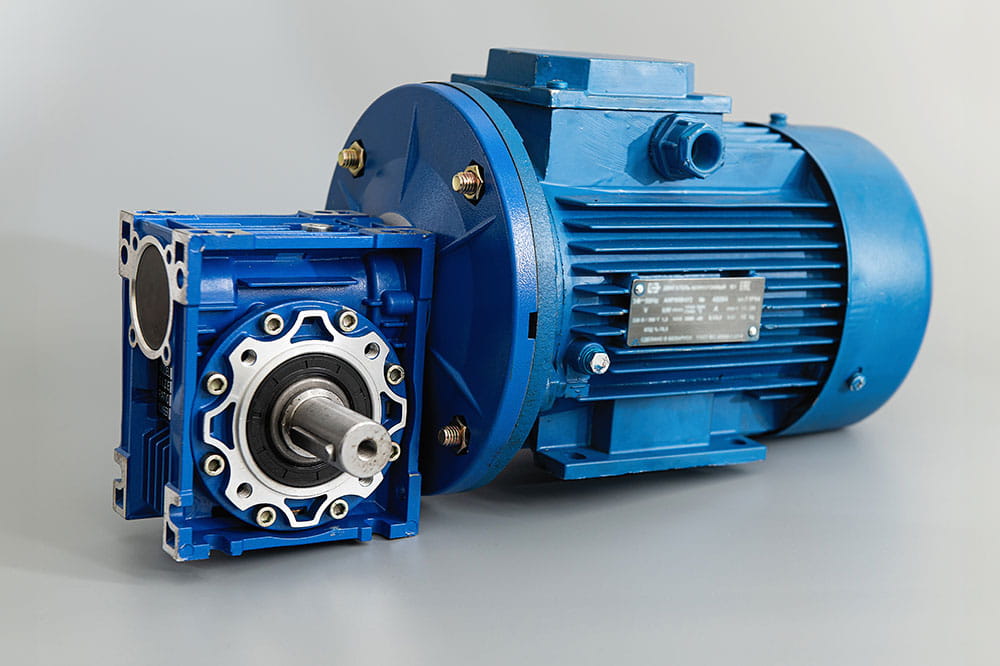

As a worldwide sealing technology leader – with vast resources and experience – Freudenberg is uniquely positioned to provide exceptional engineering, manufacturing and customer support wherever you do business. Every part is manufactured to the highest industry standards, with documented traceability.

With more than 170 years of experience, we offer the industry’s broadest lineup of standardized materials and continually develop new ones for customer applications. With our own development lab, our own in-house mixers and an array of 1,700-plus compounds made from 850 raw materials, our options are virtually unlimited.

Our team of experts is ready to help you today.

Material Overview

News and Stories on Our Materials

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new