Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

10.07.2023 | Press release

Benchmark For New Elastomer Compounds

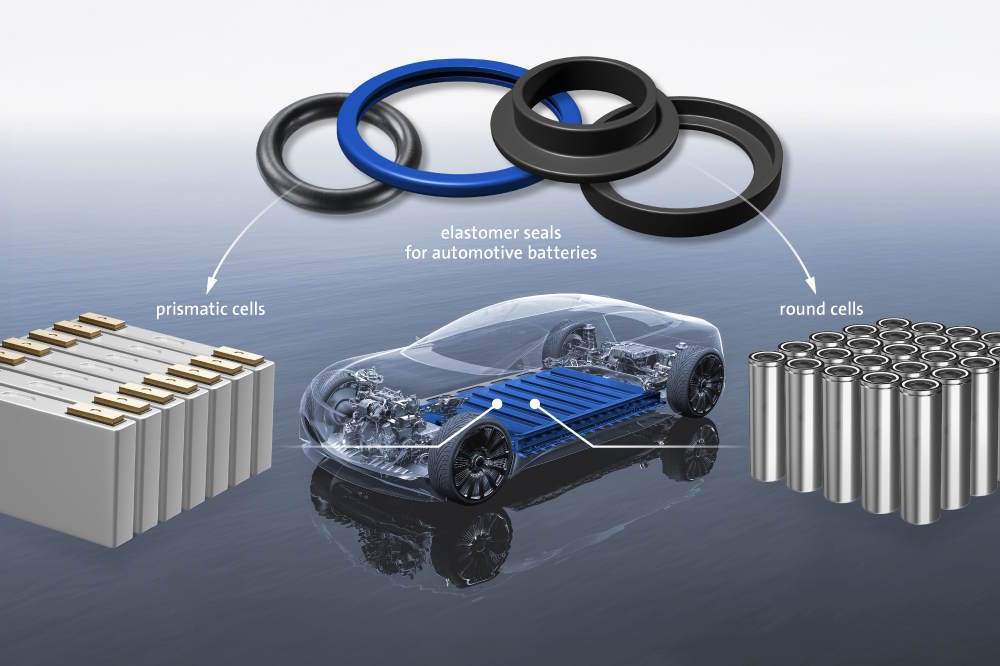

Weinheim, July 10, 2023. Freudenberg’s new development for the vulcanization of chloroprene rubber eliminates the need for ethylene thiourea (ETU) as an accelerator – while still meeting the strict requirements of the automotive industry. With this innovation, the company follows its own sustainability goals and also sets a benchmark for new elastomer compounds.

Using ethylene thiourea (ETU) as an accelerator in the vulcanization of chloroprene rubber is standard in the industry. Products with this accelerator have been used successfully for decades and show very good values in terms of low-temperature flexibility as well as the required resistance to media such as greases and lubricants. Due to the risk of reproductive toxicity and its damaging effect on fruit, however, ethylene thiourea should no longer be used if its omission is technically and economically feasible. But so far there have been no alternatives that offer a similar performance or even met the requirements.

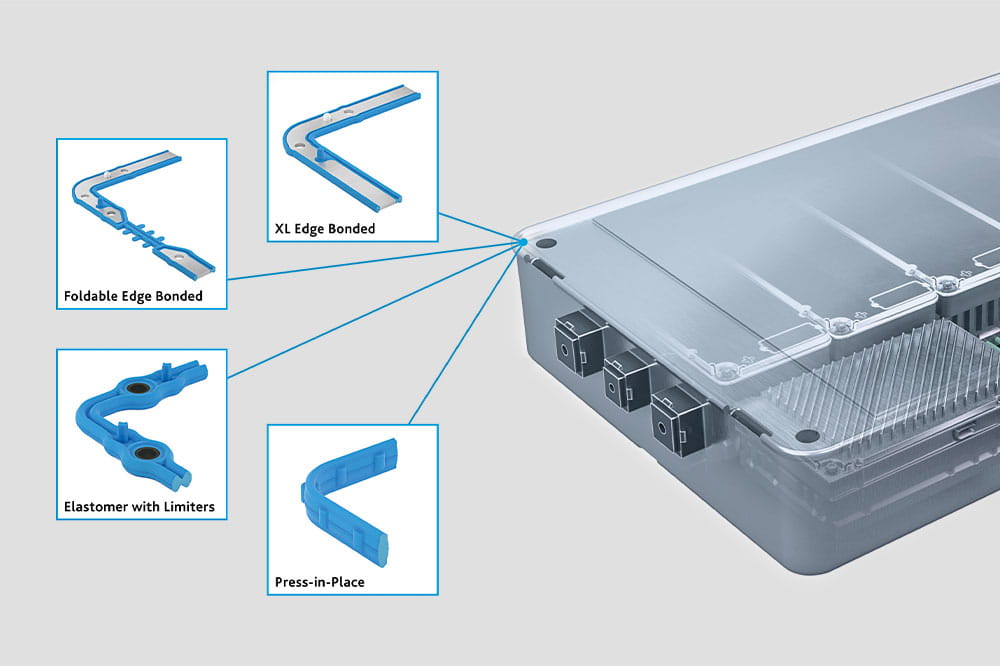

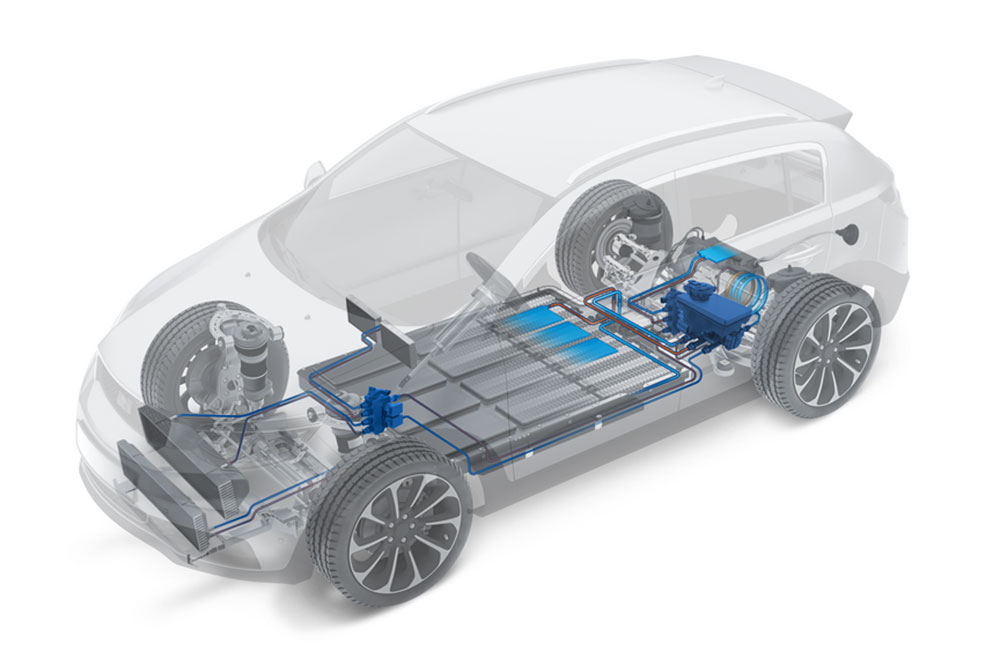

That is why Freudenberg Sealing Technologies has developed new elastomer compounds that require no ethylene thiourea accelerator in the manufacture of products made of chloroprene rubber. One of the company’s already successful applications of ETU-free products in the automotive sector is in sealing bellows for joint seals in tie rods, control arms and wishbones. They protect the moving parts from external influences and the leakage of lubricants. When it comes to the development of new, ETU-free elastomer compounds, Freudenberg Sealing Technologies is one of the pioneers and is currently considered a benchmark in this area.

New material compound meets different requirements

For the specialists at Freudenberg Sealing Technologies, the challenge lay not only in eliminating ETU and other harmful accelerators, such as the additional use of tetramethylthiuram disulfide (TMTD), but also in reconciling this with the increased requirements placed on new compounds. In addition to the most efficient vulcanization possible, these include three key requirements that influence each other: significant low-temperature flexibility after targeted aging, compatibility with greases and lubricating additives in direct contact with the sealing bellows, and resistance to hydrolysis. Another goal was to bring the compound optimization into conformity with current and future customer requirements. The specialists at Freudenberg Sealing Technologies succeeded in launching new compounds into series production.

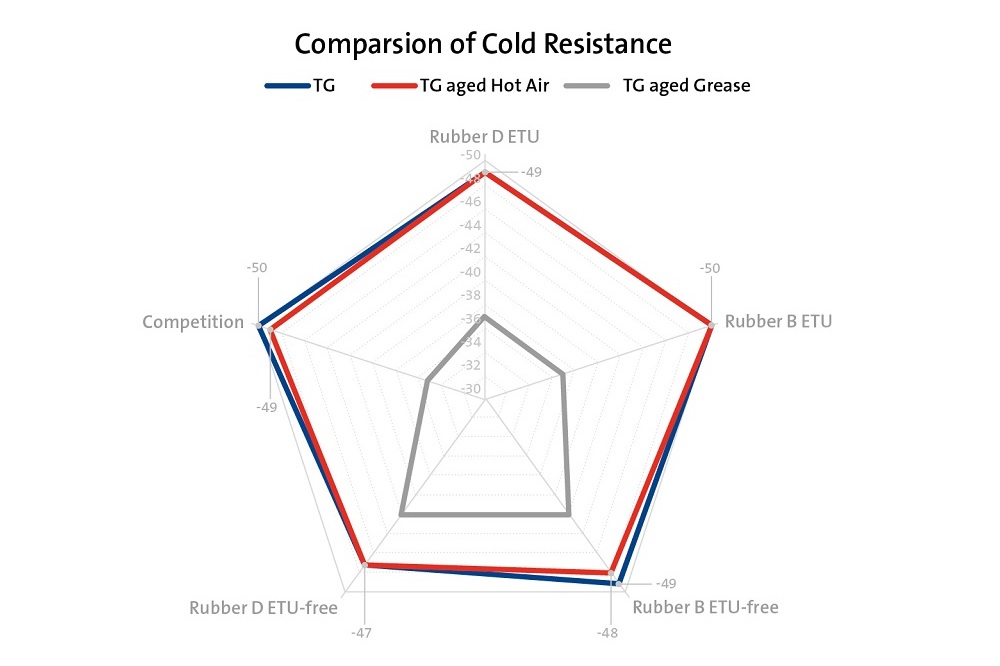

In addition to the statistical design of experiments (DOE), failure analysis, and optimization of mixing processes, the methods used in the compound development included thermal analyses such as differential scanning calorimetry (DSC). This is used to determine key parameters such as the melting and crystallization temperature, relaxation, glass transition temperature, degree of vulcanization, and more. The measurements have shown that one of the most important requirements, for example – behavior in the low temperature range – is being met extremely well. This is also confirmed by feedback from customers in the automotive sector that are already using ETU-free sealing bellows for joint seals in tie rods, control arms and wishbones. They confirm that the new material has much more stable values at low temperatures than other products on the market – which is a significant benefit when used continuously. After artificial aging in water and relevant greases, other parameters such as tensile strength and elongation at break are also within the requirement specifications. This was verified after the corresponding preconditioning with 7 days at 70 °C (158 °F) in grease, 10 days at 80 °C (176 °F) in water and 48 hours in 70 °C (158 °F) hot air.

Reducing administrative work

Substituting the harmful accelerator ethylene thiourea in the cross-linking of chloroprene rubber is only one benefit offered by the new elastomer compound. Another advantage is the considerable reduction in administrative work. Since the beginning of 2021, a reporting obligation in the SCIP database of the European Chemicals Agency ECHA has been in effect for all products containing specific quantities of Substances of Very High Concern (SVHC). This applies to the entire supply chain from the manufacturer to the end customer, which makes it very complex. Thanks to the new development, the additional reporting requirement is eliminated, and the reporting can be carried out as before via the existing and globally standardized exchange and management system IMDS.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!