Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

11.07.2023 | Story

The Right Material Mix for the Highest-Quality Sound

When people hear their favorite band playing either at home, in the car or on stage in a concert hall, almost no one takes note of the crucial role that rubber rings play behind the scenes. They ensure that speakers deliver the right sound reproduction to audiences.

A common yet little-known product is produced in Blackburn, a city of 130,000 near Manchester in northwest England. Hardly anyone is consciously aware of it or even knows its name. It is also a product that music lovers around the world should deeply appreciate. It makes sure that listeners hear the right audio quality at festivals, in concert halls and even in their own homes. We are talking about loudspeaker “surrounds” that enclose the speaker's cone at its outside edge and hold it in check.

Loudspeakers

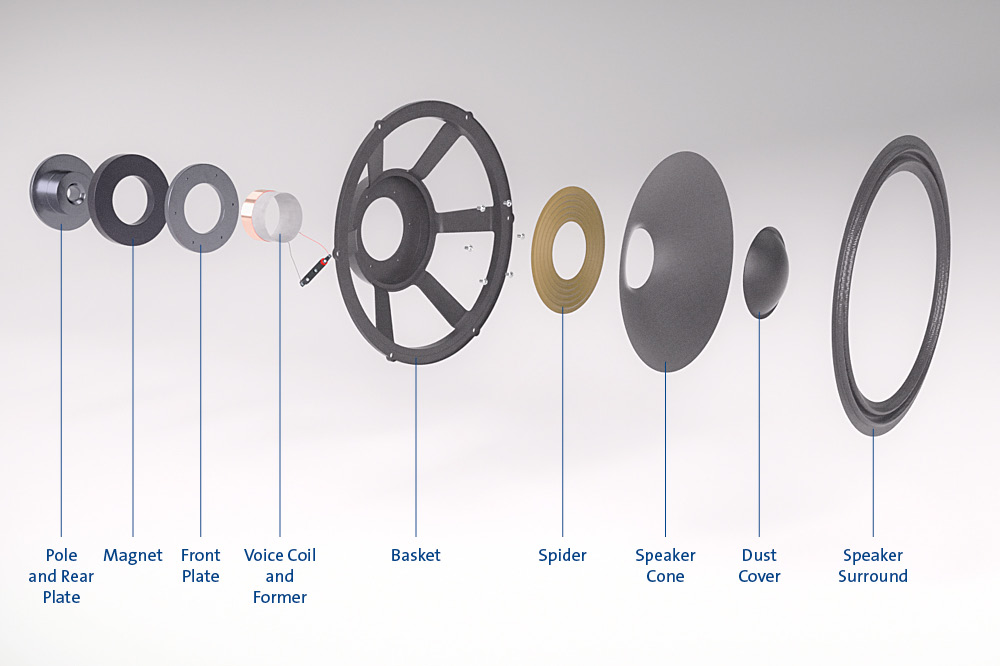

Speakers contain a range of components. Aside from the cabinet, the only visible elements are the speaker cone with a dust cap at its center and the surround that encircles the cone. The cylindrical pole is invisible in the interior. It is electrified and thus imparts vibrations to the coil surrounding it and in turn the speaker cone. The interior components are embedded in a cylindrical basket. The surround adjoining the exterior of the cabinet creates a connection between the basket and the diaphragm, giving the entire assembly stability. If the surround would be missing, the agitation would cause the cone to vibrate uncontrollably. The audio experience would be unacceptable. Even defective surrounds have an immediate, negative impact on the sound, which is very distorted.

Freudenberg Sealing Technologies develops and manufactures surrounds of this type in Blackburn. Speakers containing the company’s surrounds have already accompanied various famous artists on their world tours. They are on duty in the loudspeakers of numerous stadiums and concert venues as well. And they are incorporated into cars and in smart speakers of every size. The diameter of the surrounds can range from just a few centimeters to more than a meter. “We are currently producing speaker surrounds with a diameter of 27 to 371 millimeters (about 1 to 14 inches),” said Market Segment Manager Andrew Parkinson, who supports the products’ manufacturing operations in Blackburn.

Rubber Surrounds for High-End Speakers

In Blackburn, Freudenberg Sealing Technologies has mainly specialized in the production of high-performance rubber diaphragms, the kind used in gas meters, to cite one example. Their highly sensitive expansion and contraction make it possible to precisely record the consumption of natural gas. It is crucial that neither temperature differences nor the age of the material distorts the results of the measurements. Much like gas meters, thin, flexible and yet robust rubber diaphragms are in demand for the surrounds used in loudspeakers. Despite their very different uses, it made sense to expand the business field to include this speaker accessory.

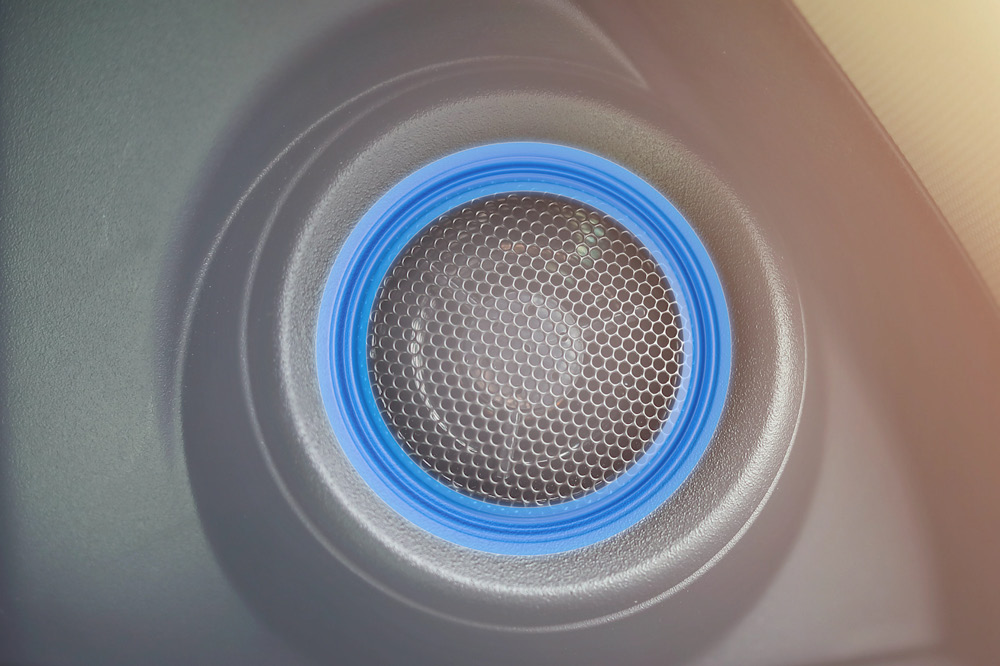

Indoors and outdoors: Speaker surrounds by Freudenberg Sealing Technologies are built to resist the toughest conditions.

Today the England-based material specialists produce up to 85,000 speaker surrounds per year. Consumers can find these specifically formulated rubber surrounds in use at speaker manufacturers throughout Europe. Freudenberg Sealing Technologies is manufacturing them in Malaysia – especially when extremely high volumes are needed – as well as in Blackburn. The company is even able to produce tiny volumes in the double-digit range. In the end, the Freudenberg Business Group produces premium products for high-end speakers with this approach, and manufacturers are happy to make the investment in them. After all, some tower loudspeakers cost up to 30,000 dollars.

Crucial Detail: The quality of the speaker surround has a great affect on the audio quality of a loudspeaker.

Damping and Controlling the Speaker Diaphragm

But customers don't usually order extremely small quantities. They have a clear idea of how many speaker units they will sell by the time the products are launched. And they know how crucial good audio is for their products and their customers’ listening experience. This is where the seemingly nondescript surround plays an important role. Even at full volume, the rubber surround dampens and controls the vibration of the speaker's cone. This makes it possible to achieve or maintain the frequency range desired by the manufacturer, from tweeters (2,000 to 20,000 Hz), across the midrange (500 to 4,000 Hz) all the way to subwoofers (20 to 2.000 Hz).

At the same time, the surrounds guarantee a consistent vibration reverberation. “The surround's added value could be compared to the spring suspension of a vehicle,” explained Javier Garduno, Segment Manager at Freudenberg-NOK Sealing Technologies. “When a car is equipped with air suspension instead of steel suspension, it rides much more quietly and smoothly. Similarly, high-quality surrounds from Freudenberg significantly improve the audio quality by damping the vibration of the speaker's cone. If the surround is of poor quality, the audio from the speaker could be tremendously warbled.”

A Sound Signature Is Like a Fingerprint

Inquiries from the loudspeaker industry are on the rise thanks to the quality of the Freudenberg surrounds. At the start of the collaboration, customers send a drawing of their model and its requirements to the experts in Blackburn. The manufacturers do not merely prescribe the surround's design but the frequencies and the damping effects they expect as well. They have various applications in mind and are oriented to desires of the target groups when it comes to the sound, whether they are theater-goers, classical music lovers or rock fans. Nonetheless, not every loudspeaker manufacturer wants to achieve the same sound quality. In the end, it is a question of their own sound signature, comparable to a fingerprint, that distinguishes every speaker manufacturer.

The search for the best possible material mix begins in Blackburn with the goal of achieving the right sound, based on the requirements from the customer. “We then create a prototype that we send to the customer for testing. It is assembled with the rest of the electronics that go into the loudspeaker and investigated in sound chambers and with acoustic testing devices to see whether the desired sound is achieved,” Garduno said. The process can take between six and 18 months from the submission of the speaker drawing, then proceeding to the creation of the material mix and the testing of the prototype, and finally the production of the finished product.

We mobilize the entire body of our expertise and our understanding of the industry to provide speaker manufacturers with the surround that they want.

Andrew Parkinson, Market Segment Manager, Freudenberg Sealing Technologies

Acoustic Expertise Meets Material Science

At Freudenberg Sealing Technologies, Dynamic Mechanical Analysis (DMA) plays an important role in the search for the right material. The process makes it possible to examine the relationship of frequency and temperature to rigidity, along with the damping effects of particular material mixtures. The experts are able to move towards the right material composition and damping characteristics for the desired sound and the specified band of frequencies. Material science as well as an understanding of acoustics is needed. Surrounds can generally be made from foam as well, but foam is not nearly as durable as rubber. At its facility in Blackburn, Freudenberg can create the right rubber mixture at any time. The DMA helps to ensure that the solution matches the requirements. “We mobilize the entire body of our expertise and our understanding of the industry to provide speaker manufacturers with the surround that they want,” Parkinson said.

He and his team always work with a base material such as NBR, a nitrile rubber. NBR guarantees considerable design flexibility. The option of adapting it to different customer desires is a given from the outset. Then it comes down to achieving the required frequency range while promoting the quality of the sound and the reverb. This requires the admixture of other chemicals. With the help of additional ingredients, Parkinson and his team can simultaneously produce highly ozone and UV-resistant synthetic rubber – which extends their service life and is especially desirable for outdoor speakers.

DFT Process Provides Optimal Rubber Surrounds

The so-called Dispersed Fiber Technology (DFT) is a special method offered by Freudenberg Sealing Technologies. Materials produced with this technology are a cross between a purely homogeneous and a fabric-reinforced mixture. The latter are certainly more robust but offer less design flexibility. Materials produced with DFT also contain special fibers. But the fill rate for them can be gradually adjusted down to the smallest quantities. That means the profile of the material mixture can be determined precisely to meet the customer's need for a particular sound and frequency range. Rubbers improved in this way are neither affected by large volumes nor high loads, and yet they offer great design flexibility. For example, DFT enables the production of variable wall thicknesses, whatever material mixture serves as the base. From this perspective, DFT is unique. Customers who opt for DFT-produced surrounds get an absolute premium product in return. And in the end, music lovers throughout the world are rewarded with the best possible sound experience.

Do You Want to Improve Your Speaker Experience?

Click here for exclusive insights and info material on Freudenberg Sealing Technogogies' Dispersed Fiber Speaker Surrounds offerings.

More news on the subject Technology & Innovation

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new