Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

22.01.2019 | Press release

The New Diversity

Weinheim (Germany), January 22, 2019. E-fuels are expected to improve the climate footprint of conventional powertrains. New findings in material research by Freudenberg Sealing Technologies show the impact that OME, a substitute for diesel fuel, has on the long-term stability of seals. The research has found that seals made from an already widespread material, fluoro rubber (FKM), are basically suited for renewable fuels. But there are surprisingly large differences between specific FKM varieties.

The auto industry is not just betting on electric powertrains as a way to reduce CO2 emissions from road vehicles. Even conventional internal combustion engines are expected to become more climate-friendly thanks to e-fuels. They are liquid or gaseous vehicle fuels that are not refined from fossil petroleum – they are created from carbon and hydrogen with the help of solar and wind energy. They can be mixed with conventionally produced fuels, bringing a reduction in CO2 emissions if the carbon employed is either extracted in advance from the air or from unavoidable industrial emissions. Until now, there has been very little experience with the effects of the new fuels on the long-term stability of seals in fuel systems.

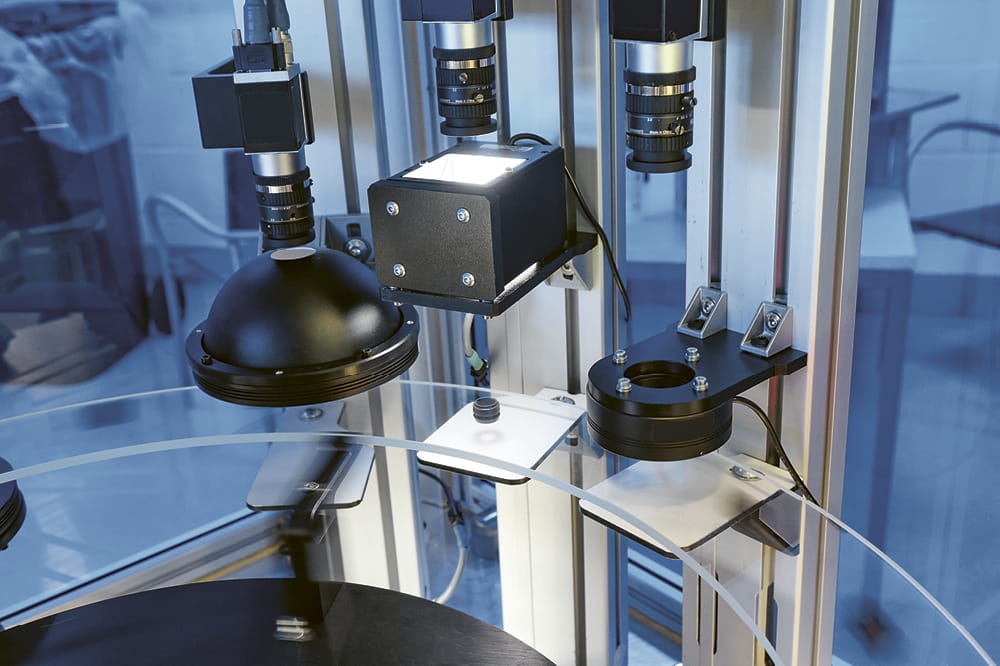

Auto supplier Freudenberg Sealing Technologies has now explored the behavior of sealing materials that are exposed to OME (oximethylene ether) in exhaustive testing for the first time. The fuel used in the tests consisted of mixtures of standard diesel fuel and OME, which was present in concentrations ranging from 10 to 30 percent of volume. Other tests were carried out with pure OME and with 100 percent fossil diesel fuel as references. The volume expansion and the change in mechanical strength of various sealing materials, namely FKM with different levels of fluorine content, FFKM, NBR and EPDM, were measured. In line with industry standards, they were stored for 168 hours at a temperature of 125°C in the test media. Additional exposure tests were carried out with specific fuel combinations over a period of 1,000 hours so long-term effects could be studied. The more the material swelled over this period, the lower its strength, which becomes especially clear from a decline in elongation at break.

Surprising results, even for the experienced material experts at Freudenberg Sealing Technologies

Why do experts immediately turn to relatively expensive polymers such as FKM in the evaluation of a new fuel system? Dr. Boris Traber, the head of Global Material Development at Freudenberg Sealing Technologies, has this explanation: “Fluorine atoms are significantly larger than carbon atoms, so they form a kind of protective shield for the seal’s basic material,” he said. “Fluorine-carbon compounds are also highly symmetrical, which neutralizes their charge concentration. The effects that we were able to observe are not unlike a coated pan upon which both water and grease form droplets.” Carried over to fuels, this characteristic shields both the nonpolar ingredients such as hydrocarbons and the polar ingredients such as water and ether, which leads to less swelling.

The results even surprised the experienced material experts at Freudenberg Sealing Technologies: In nearly all of the seal materials that were tested, pure OME led to volume expansion that far exceeded the usual swelling values. The image that emerged in FKM compounds was one surprise: One would have expected that the swelling volume would decline with rising fluorine content. But that wasn’t the case. The expansion in volume was not linear in relation to the fluorine content. This anomaly can be traced back to a correlation with hydrogen content in this kind of FKM. A higher proportion of hydrogen also leads to high swelling values. Accordingly, the perfluoro rubber (FFKM) that was tested exhibited very good values as well, although it is significantly more expensive than other options. An EPDM also showed low swelling in pure OME.

Tests for more than a decade

The test series also showed that the tested FKM materials showed a much lower level of swelling in an admixture with up to 30 percent OME by volume. Traber is encouraged by this: “We could immediately substitute OME for a certain share of fossil diesel fuels,” he said. But he also sounds a note of caution. “Our experience shows that – especially outside of Europe – actual fuel quality can fluctuate greatly due to uncontrolled impurities. So experts should always be consulted during the selection of sealing materials.”

For more than a decade, Freudenberg Sealing Technologies has been carrying out tests to investigate how fluctuating fuel composition affects sealing materials. In the company’s own labs, researchers have explored the swelling behavior of sealing materials in soy methyl ester and hydrogenated plant oils, for example. They have also developed their own test stand design for these inquiries. It can be used to investigate the permeability of a sealing material that is constantly exposed to a particular fuel for a relatively long period. Here the “door-opener” phenomenon was observed: Small polar molecules such as methanol have this effect on otherwise impermeable hydrocarbons. The permeability varies over time.

To sum it all up, the FKM materials proved to be superior in all the test series. It was not just the fluorine content but rather the entire material structure that was crucial for strength and leak tightness. As a result, Traber sees no fundamental obstacle to the introduction of renewable fuels. “Even today we have suitable materials available if the configuration is right.”

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.