Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

01.03.2017 | Press release

Freudenberg’s Always Essential Components and Technical Expertise Showcased at IFPE

Las Vegas, March 1, 2017 – Among the construction, mining and agricultural machinery on display at the 2017 International Fluid Power Expo (IFPE) in Las Vegas, are some smaller but equally powerful components that help keep these industrial giants trouble-free and moving.

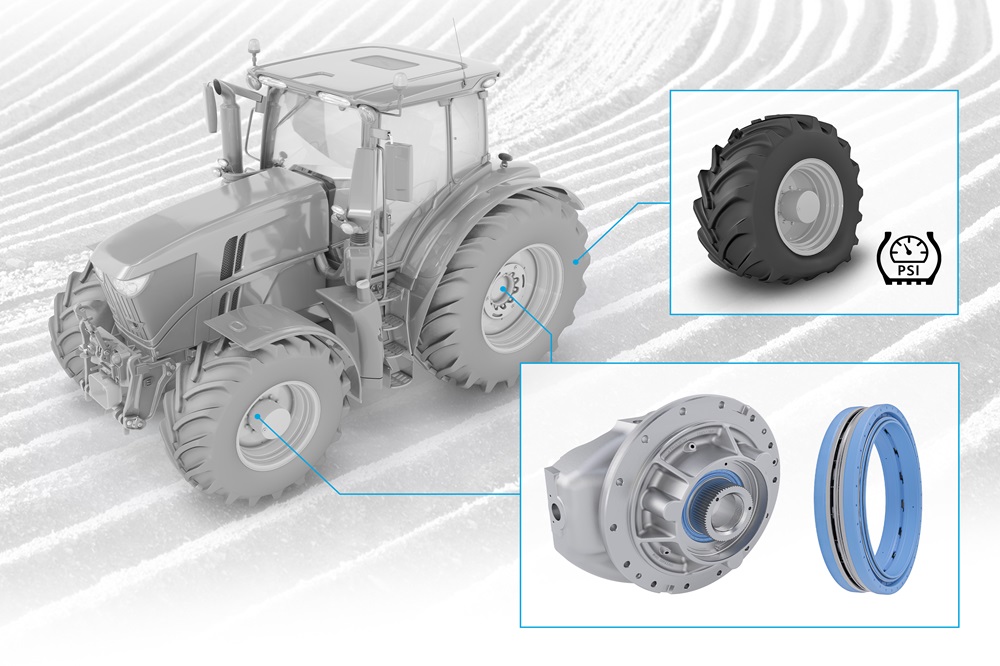

Freudenberg Sealing Technologies’ seals, gaskets and hydraulic accumulators are “Setting Benchmarks” in reliability, durability, productivity, quality and comfort. They are custom engineered to address some of the most difficult environmental issues facing industrial equipment systems today. Those issues include extreme temperature variations, higher operating pressures, longer service life, improved fuel economy, lower emissions, harsh contaminants and new material compatibility requirements.

The company will showcase a portfolio of these advanced sealing products and hydraulic accumulators at its IFPE booth (#82630) March 7-11. Displays will feature new cassette and combi seal designs; a large variety of radial shaft seals including premium pressure seals, central tire inflation system seals and multi-lip seals; engineered plastic components including the company’s unique Levitas and Levitorq products; lightweight accumulators and compensators; proprietary elastomeric, polyurethane and Polytetrafluoroethylene (PTFE) materials; and Freudenberg’s Xpress technology and capabilities.

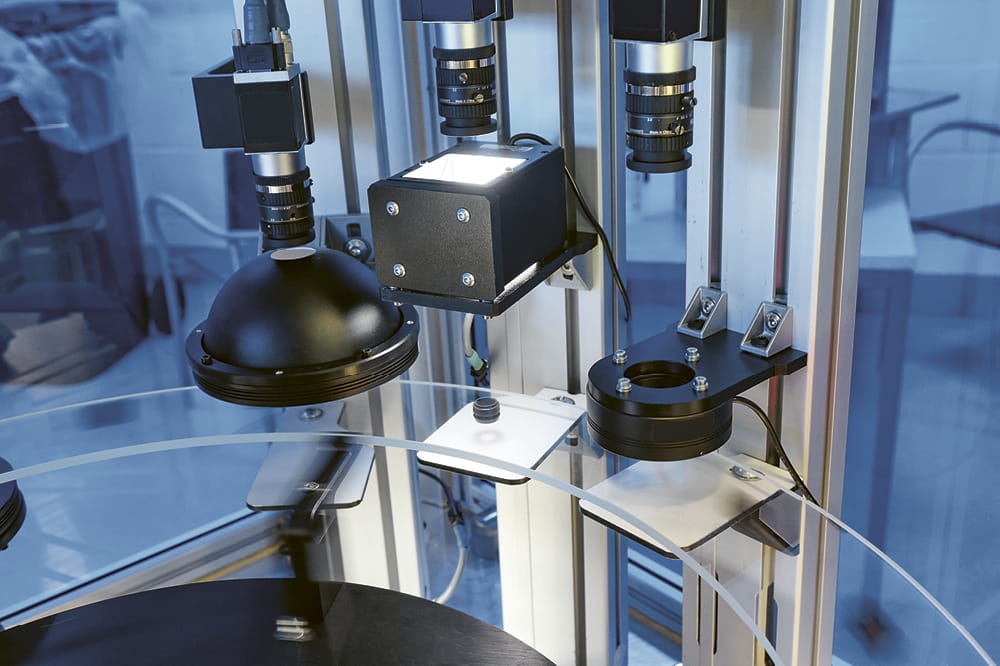

In addition, company experts will conduct daily booth presentations that highlight some of the innovative design, engineering, testing and assembly process capabilities that Freudenberg Sealing Technologies uses to evaluate and address significant industry challenges. Topics include:

- Development of an innovative diaphragm accumulator design and assembly process

- Understanding contamination ingress into hydraulic cylinders through alternative, innovative test methods

- Innovative cassette seal designs for speed, axial movement, and contamination

- Development of high performance plastic thrust bearings to reduce system friction using innovative designs.

- Advanced off-highway emission strategies using existing technologies and the innovative, new, cost-effective technologies

Presentations are scheduled daily at 10 a.m. and 2 p.m.

“As customers’ technical needs evolve, Freudenberg Sealing Technologies continues to focus on the development of advanced product and process solutions that set new benchmarks in areas like reliability, durability, fuel economy and comfort,” said Joel Johnson, Vice President of the company’s Mobile Machinery sector. “Extended lifecycle requirements are, in particular, a customer priority, and our components function flawlessly in the most extreme applications because of the material research, engineering and testing we invest in every product solution we offer.”

“Freudenberg-NOK is founded on a rich heritage of technical competency and global manufacturing expertise. We are proud to support the success and growth of our customers and communities across North America,” said Matthew Portu, President, Freudenberg-NOK. “We adhere to strong business principles that drive innovation, continuous improvement, customer value and environmental responsibility into every corner of our business. Our people are recognized as industry experts.”

The company has deep roots in the automotive industry and has used its industrial expertise to introduce innovative component solutions like its Low Emission Sealing Solutions (LESS) product portfolio which focuses on reducing powertrain friction, lowering emissions, accommodating smaller installation spaces and incorporating lightweight material technologies. Freudenberg’s Levitas seal, for example, which floats on a hydrodynamic cushion of oil reduces friction and wear to an absolute minimum.

These same technological breakthroughs are now helping customers in the fluid power, construction, agriculture and power industries address similar evolving operational challenges.

For more information about Freudenberg at the IFPE, please visit the company’s Microsite https://ifpe.fst.com or its Twitter channel https://twitter.com/Freudenberg_FST.

Press Release Downloads

Freudenberg’s Always Essential Components and Technical Expertise Showcased at IFPE

Last update: 01.03.2017

English | PDF | 84 KB

DownloadNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.