Pharmaceutical Industry

High-Performance Seals for the Pharmaceutical Industry

Hygienic Production of Pharmaceutical Products Thanks to Sealing Materials With High Purity Standards

The purity requirements for the product and the process are particularly high in the pharmaceutical industry. This requires sealing solutions that reliably prevent contamination and can come into contact with the product without hesitation. The pharmaceutical industry consists of many different applications and processes, all of which have individual requirements. For example, the production of finished pharmaceuticals requires very good chemical resistance of sealing materials to various reactants and solvents. Very low temperatures can occur in the production of vaccines or proteins, as well as in the separation of blood, which requires very cold-resistant seals. Furthermore the sealing products have to withstand CIP/SIP cleaning agents, but must also comply with the hygienic design standards as well as the relevant legal regulations, such as USP Class VI and FDA.

Turning Regulatory Challenges Into Opportunities

Watch video play_circleApplication Examples

Related Products

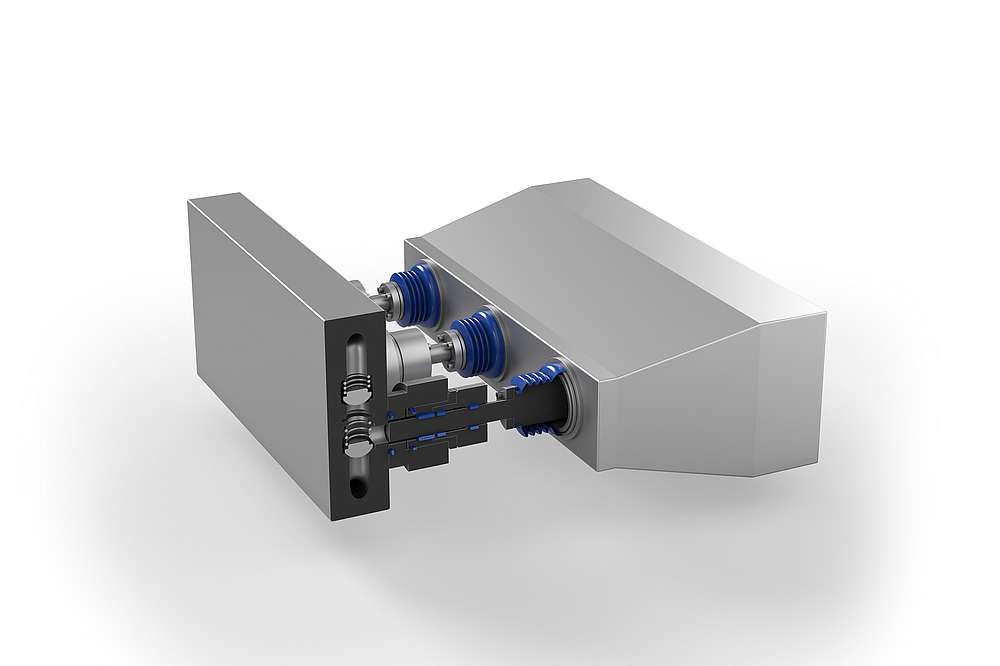

Wipers

Freudenberg Sealing Technologies offers wipers in various designs with or without metal housing. Their very good wear resistance to dust and abrasion is a special feature of the wipers. Our experts would be happy to advise you on your individual requirements and develop customized solutions for you.

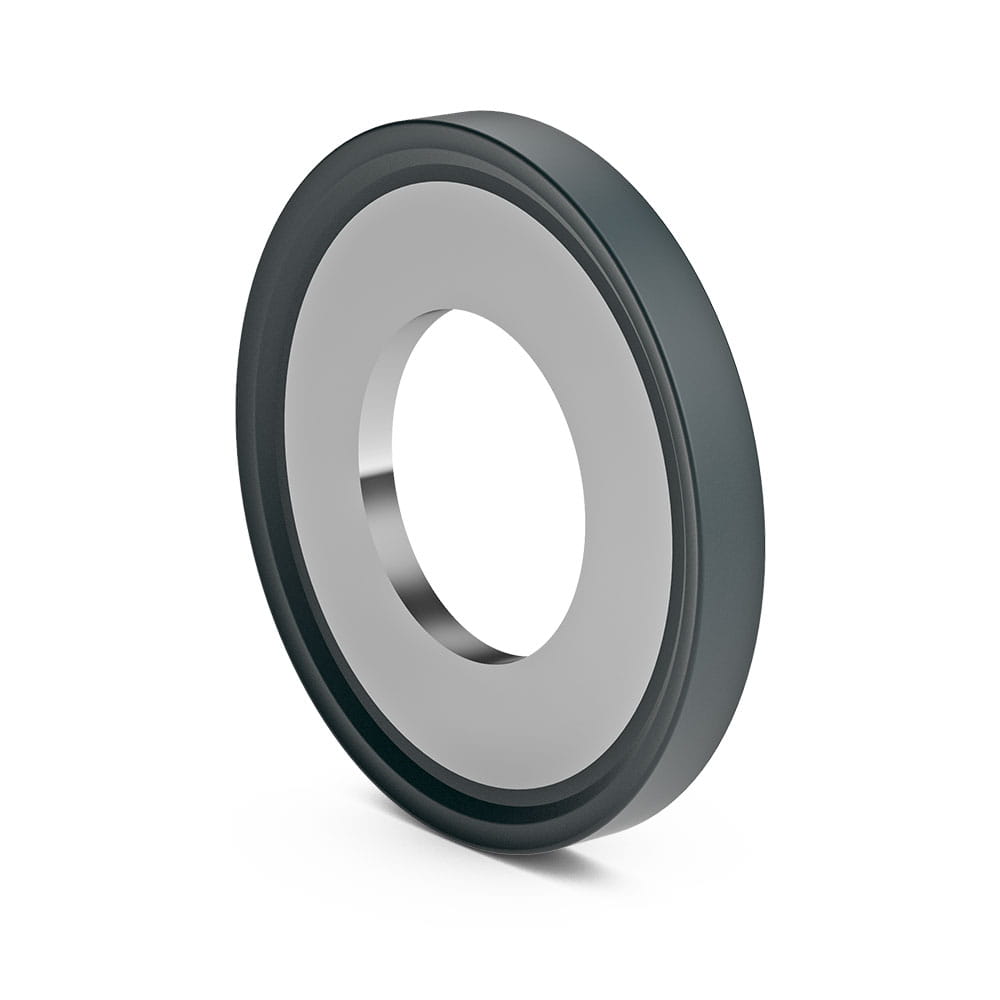

Radial Shaft Seals

Freudenberg Sealing Technologies offers special designs of radial shaft seals for the pharmaceutical industry, including the Radiamatic® HTS II, the Simmerring® BlueSeal, and the Simmerring® B2PT. Their key feature is their resistance to media and extreme temperatures – the pharmaceutical substances only come into contact with high-performance materials like PTFE and Fluoroprene® XP, which conform to all relevant legal standards. Radial shaft seals are available in various designs, including variants that meet Hygienic Design standards.

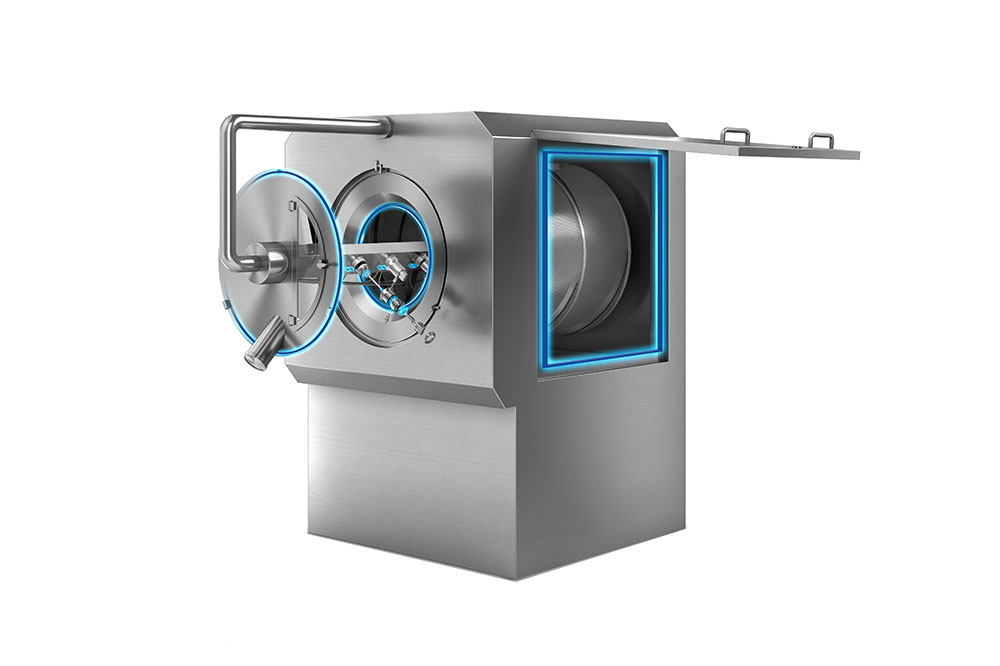

Hygienic Product Line

With the product line for hygienic plants in the process industry, Freudenberg Sealing Technologies offers a unique product portfolio for hygienic applications. This includes not only the Hygienic Pressure Seal and Hygienic Forseal, which are made of the premium PTFE Quantum®, but also dead-space-free radial seals for seat valves, radial shaft seals such as the Radiamatic® HTS II 9539 VL with an advanced sealing lip, shaft seals, butterfly valve seals, Hygienic Usit® rings and aseptic O-rings.

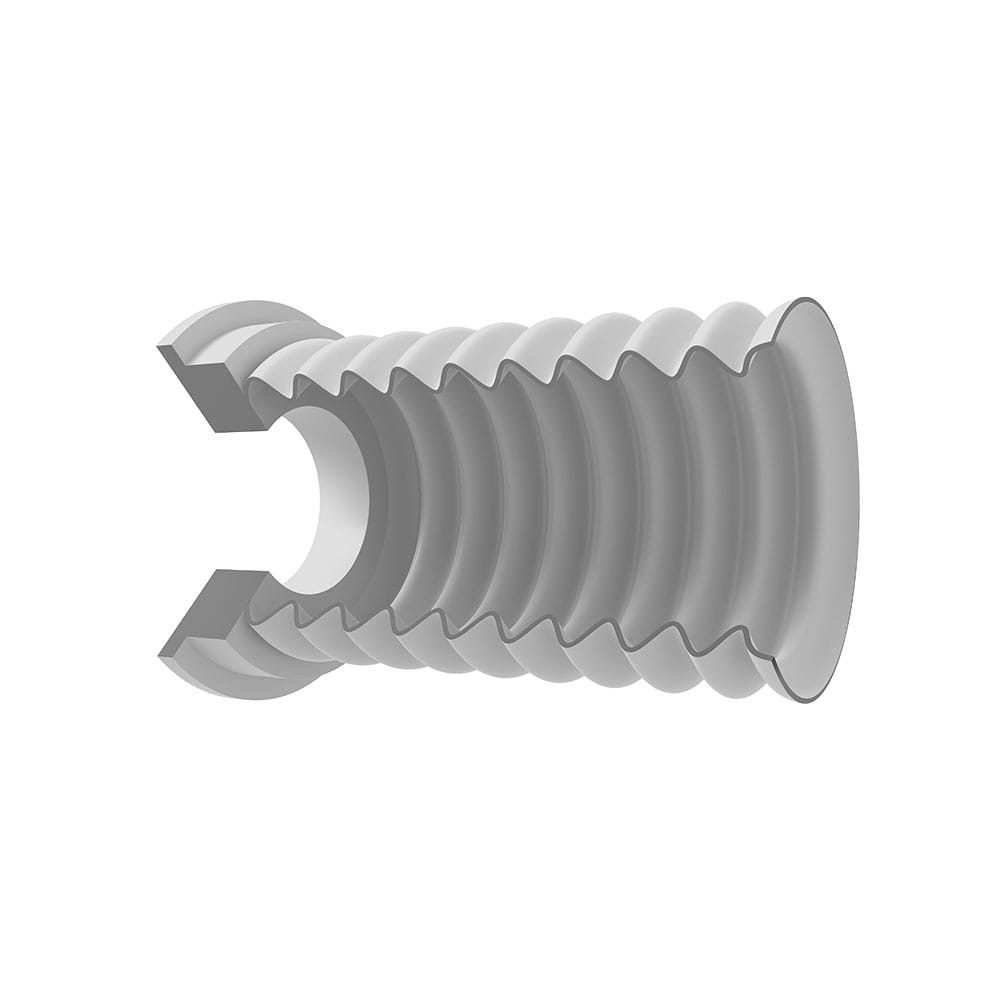

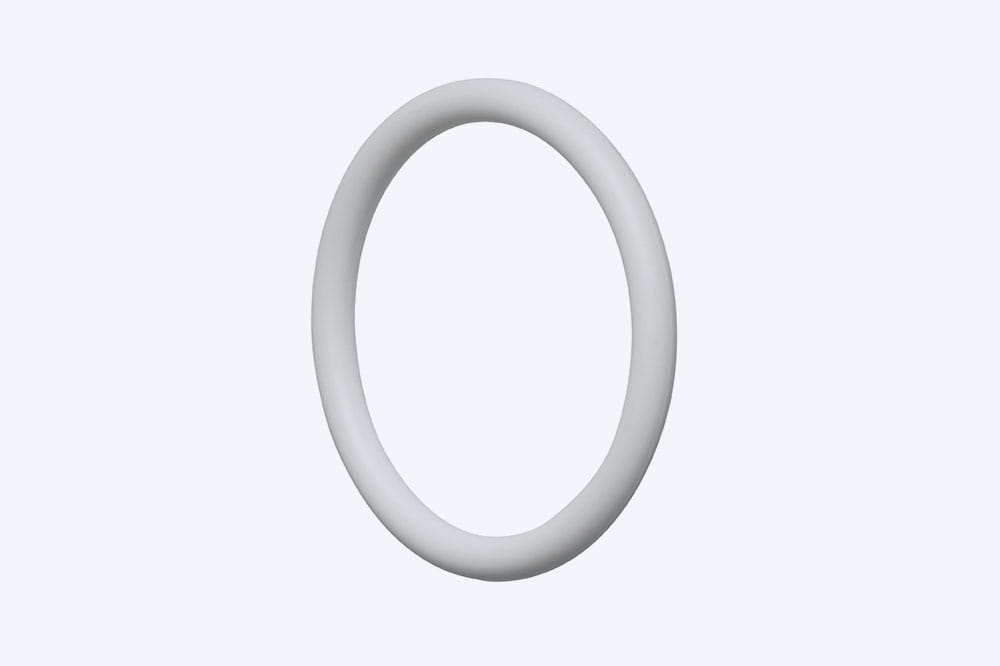

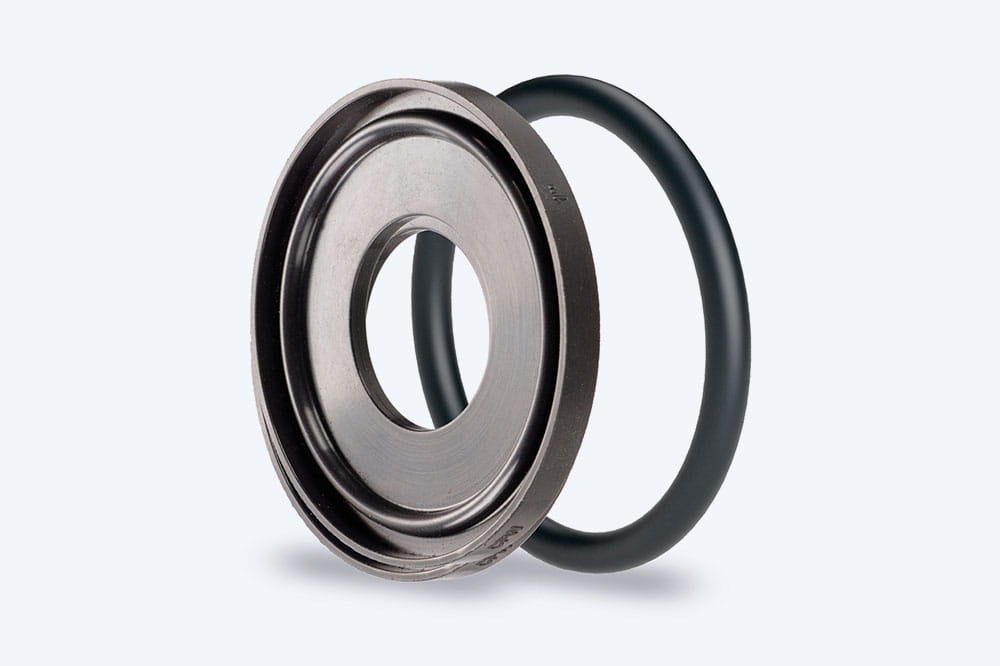

O-Rings

O-rings are used as universal sealing elements in almost all applications and offer an excellent price-performance ratio. At Freudenberg Sealing Technologies O-rings can be manufactured in all elastomer materials, such as 70 EPDM 291, 75 Fluoroprene® XP 41 or 75 Simriz® 494. These have all relevant approvals for the pharmaceutical industry. In addition to round O-rings, oval, rectangular, semicircular and x-shaped cross-sections are also possible.

Bellows

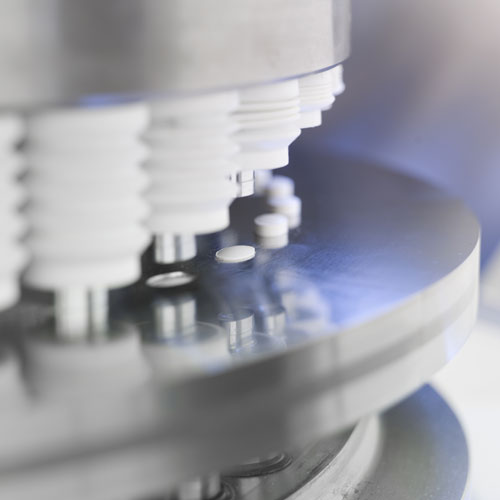

PTFE bellows can be used to protect moving machine parts, such as the punches in tablet presses. For the pharmaceutical industry, we use high-quality PTFE materials that have high media and temperature resistance and comply with all relevant regulations. Depending on the application, we also offer bellows made of elastomer materials, such as VMQ. Please contact our experts to discuss customized designs adapted to meet your individual requirements.

Profiles and Inflatable Seals

Profile seals from Freudenberg are resistant to high temperatures, cleaning agents and other media such as water, steam, disinfectants, alkaline solutions and acids. The most important features are durability and resistance. Freudenberg Sealing Technologies also offers high-quality pneumatically activated seals made of various high-performance materials that have all relevant approvals in the pharmaceutical industry and perform extremely well due to their resistance to chemicals.

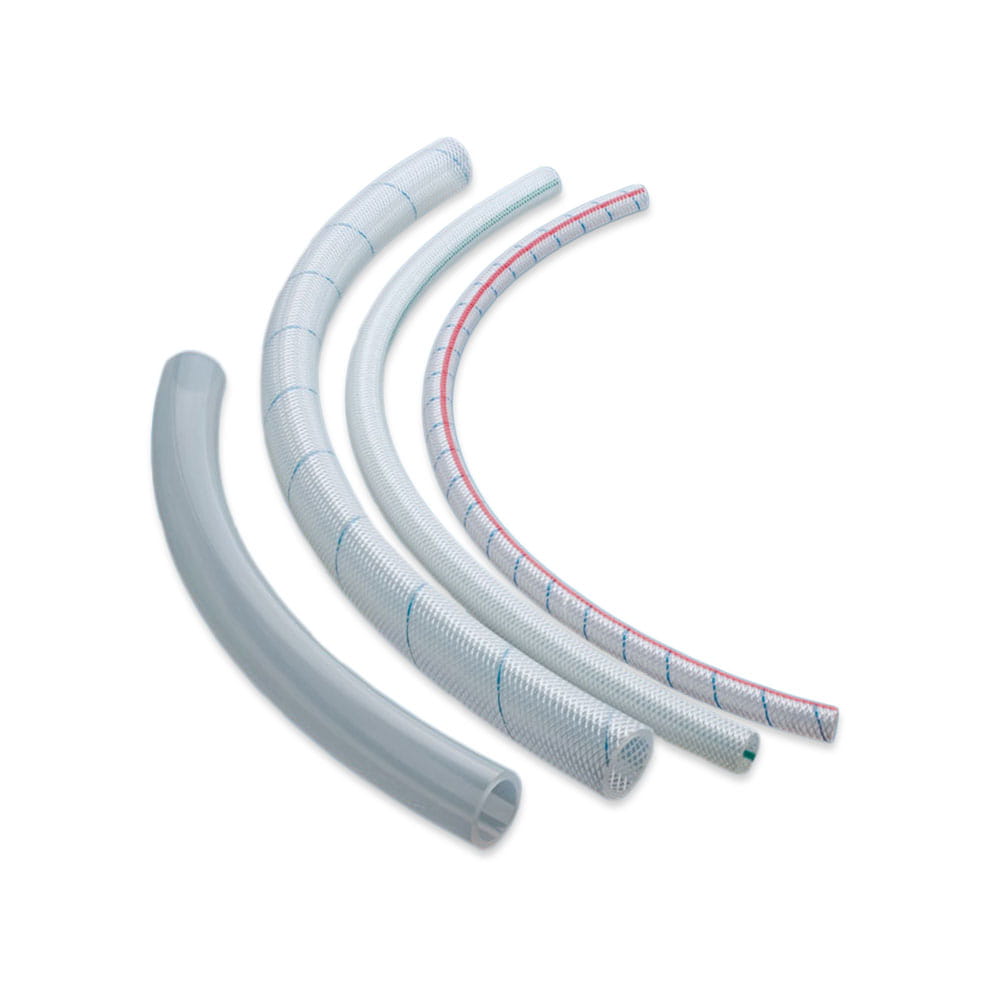

Tubing

Fluid transfer tubing for pharmaceutical, lab, and bioprocessing applications: PharmaFocus® Premium and HelixMark® are high purity reinforced, non-reinforced, and peristaltic pump silicone tubing. Thermoplastic elastomer tubing HelixFlex™ is sealable, weldable, and sterilizable. Available in a wide range of product types and sizes. Manufactured according to GMP, ISO 13485 and certified cleanrooms in the United States, Germany, and Ireland.

Visit Freudenberg Medical’s website for further product details open_in_new

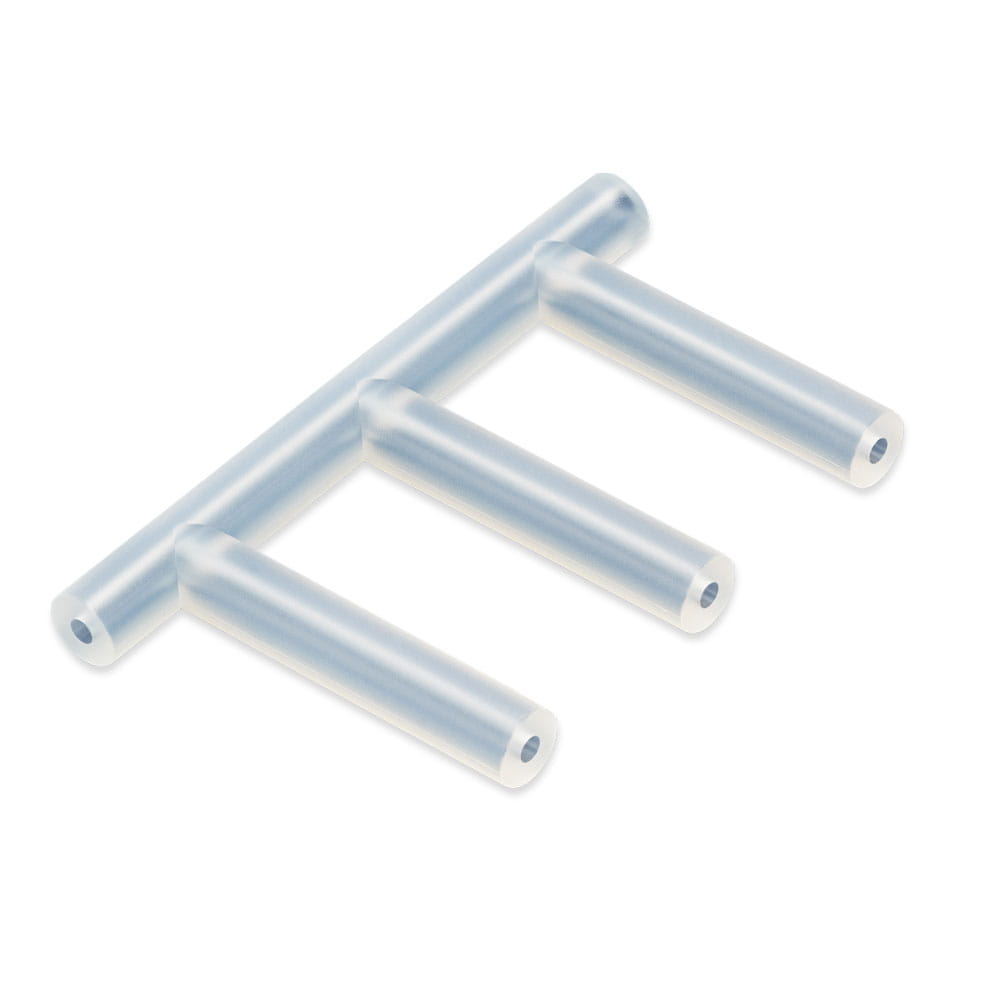

Molded Components

X & Y connectors, T-molded liners, overmolded sanitary ends, silicone stoppers, silicone clamp gaskets and many more: Freudenberg Medical manufactures components in thermoplastic and platinum-cured silicone for pharmaceutical applications. Advanced biocompatibility testing ensures compliance with the highest biomedical and pharmaceutical standards.

Visit Freudenberg Medical’s website for further product details open_in_new

Highlight Materials

White High-Performance Materials

The new white high-performance material 70 EPDM 38596 from Freudenberg Sealing Technologies has been developed especially to meet the high demands of the process industry. The material is well suited for manufacturing O-rings and sealing rings with simple cross-sections. It not only has excellent mechanical properties, but also very good resistance to standard cleaning media and steam. The very low extractables values are also an advantage that the material 70 EPDM 38596 offers.

Simriz® perfluorelastomers (FFKM) are high-end materials for the pharmaceutical industry, offering the highest degree of fluorination. Simriz® is the material of choice when other elastomers like EPDM and FKM (including high-fluorinated types) reach their limits in extremely demanding applications. This includes very high temperatures and very aggressive media. Freudenberg Sealing Technologies offers specially developed Simriz® materials like the white 75 Simriz® 38581 that comply with various legal regulations such as FDA standards.

Fluoroelastomers for the Pharmaceutical Industry

The universal material Fluoroprene® XP is ideally suited for use with CIP/SIP cleaning processes and fatty products, where EPDM is not applicable any more. In-house extractable studies prove its above-average purity on the basis of a negligibly low proportion of migrated substances. In addition, the two variants 75 Fluoroprene® XP 41 and 85 Fluoroprene® XP 43 conform to USP Chapter 87 and 88. The black FFKM material 75 Simriz® 494 is also an ideal candidate for the pharmaceutical industry due to its outstanding temperature and media resistance, excellent purity and legal compliance.

High-Performance EPDM Compounds

The materials 70 EPDM 291 (black), 70 EPDM 38596 (white) and 70 EPDM 253815 (white) were developed for the process industry. All materials show excellent CIP/SIP resistance and have all relevant conformities and approvals. All white materials from Freudenberg Sealing Technologies are outstandingly suitable for the pharmaceutical industry due to the absence of softeners. This is also evidenced by a corresponding benchmark.

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Services for the Process Industry

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new