Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Diaphragms

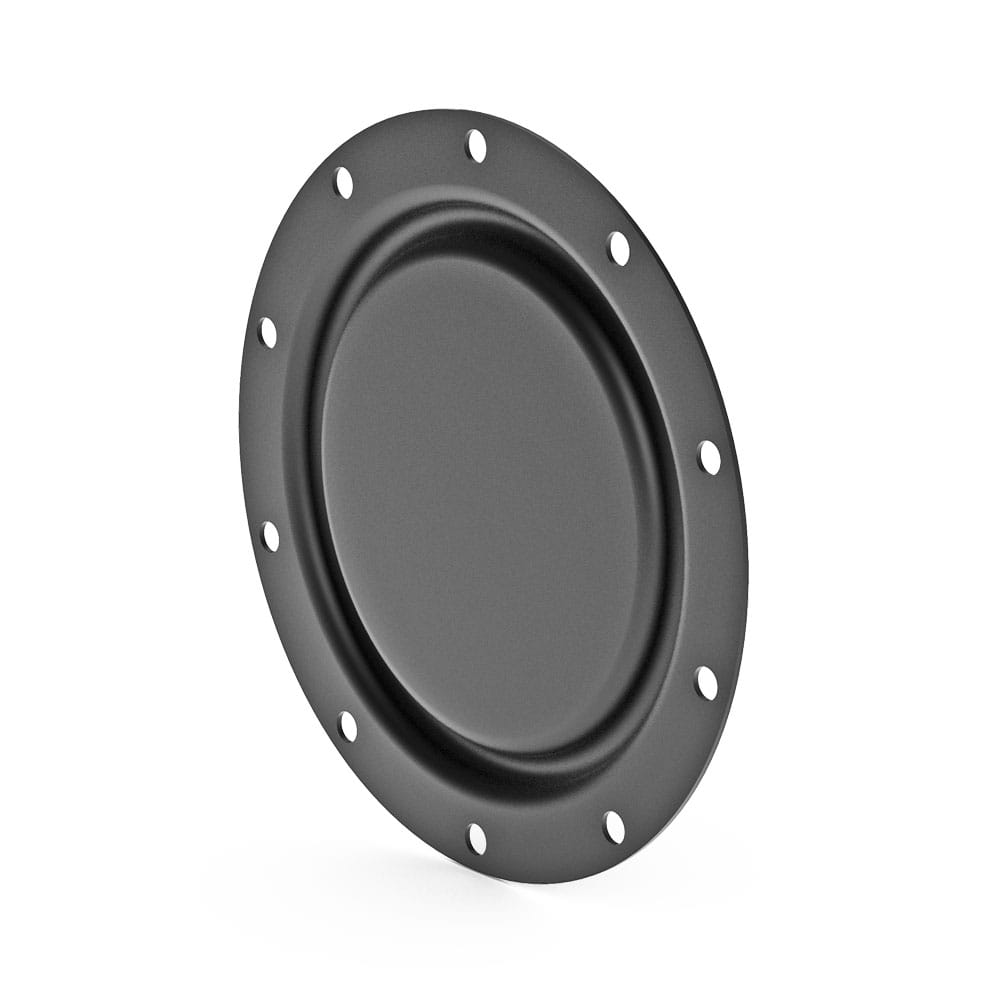

Fuel Pump Rubber Diaphragm Seals - Pump Diaphragms

Count on Freudenberg for Quality, Reliable Solutions in Nearly Every Application

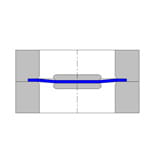

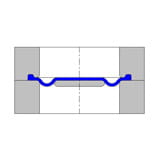

Diaphragm seals may be used in an array of applications, including pumps, pressure gauges, actuators,hydro-accumulators, valves, and regulators. Freudenberg has the expert engineering and materials expertise to provide the high performance diaphragm seals for your pressure equipment demands, in standard or custom-designed sizes and formats for any application with wetted materials. Our teams have been directly involved in the development and growth of the diaphragm seal industry, and we bring that expertise to every customer collaboration.

Trust Freudenberg for the complete range of products like flanged seals plus the global service and expertise your business deserves. Diaphragm Seals made from elastomeric materials provide specialized sealing solutions for virtually any industrial sector and can fulfill the following basic functions:

- Pump function

- Control or switching function

- Accumulation or separation function

Expert Diaphragm Seal Design and Engineering

Freudenberg puts the best engineers in the industry to work for you, with more than 50 years of experience in designing and manufacturing elastomer seals with fabric reinforcement, different types of inserts for example for flush diaphragm seals and PTFE foil coating. From our leadership at the emergence of the diaphragm seal industry through our continued growth and experience, Freudenberg has become the market leader in Europe for diaphragm seals and runs global operations. We offer extensive process design support (including simulation capabilities - FEA) and pressure testing process facilities to ensure high quality, reliable diaphragm seals for your applications with for process fluids and different fill fluids.

Leadership in Seal Design

Freudenberg excels in flanged diaphragm seals and other internal diaphragm seal designs, with engineers experienced in designing the optimum part for the application and selecting the styles and materials that will work best. We also offer the opportunity for you to collaborate directly with Freudenberg experts at your site at any point during the product development process, enabling you to gain competitive advantages from our expertise.

Freudenberg experts can discuss innovations, products, and advancements, and will share their insights on mechanical seal considerations, rubber and fabric selection, diaphragm styles and construction, and other factors like flanges specific to your custom sealing needs.

In-House Testing and Validation

At our in-house application test facility, we are able to design and test custom diaphragm seals, accurately assessing and verifying product behavior during the development. We offer a range of comprehensive tests including flow tests, consumer good life-cycle testing, and heat age or accelerated life-cycle testing through pressure instruments and transmitters, and we custom-design tests to meet customer specifications. Freudenberg diaphragms for flange connections are manufactured from compounds certified for use in specific applications, helping to ensure that your products will comply with local, national, and international standards.

Certifications Include:

FDA, KTW, ACS, USP Class VI, UL157, NSF 51, 3-A Sanitary Standards, DVGW (German Technical and Scientific Association for Gas and Water) approval according to the norm DIN EN 549 for elastomers and fabric (NBR and FKM for gas applications in combination with different types of fabric).

With more than 600 conventional elastomer blends, we provide one of the world’s largest materials offerings, covering virtually all standard elastomers, including NBR, CR, VMQ and EPDM. We also utilize high-performance, high-temperature resistant elastomers such as CIIR, ECO, FKM, CSM, HNBR, FVMQ and FFKM for example for chemical seals.

We have materials which conform to industry-specific application standards or are approved by original equipment manufacturers (OEMs).

In the processing industry, diaphragm seals are mostly found in actuators, fittings, hydraulic accumulators, pumps, compressors, valves and regulators in the food industry.

Our Products in Detail

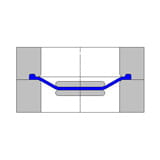

Flat Diaphragms

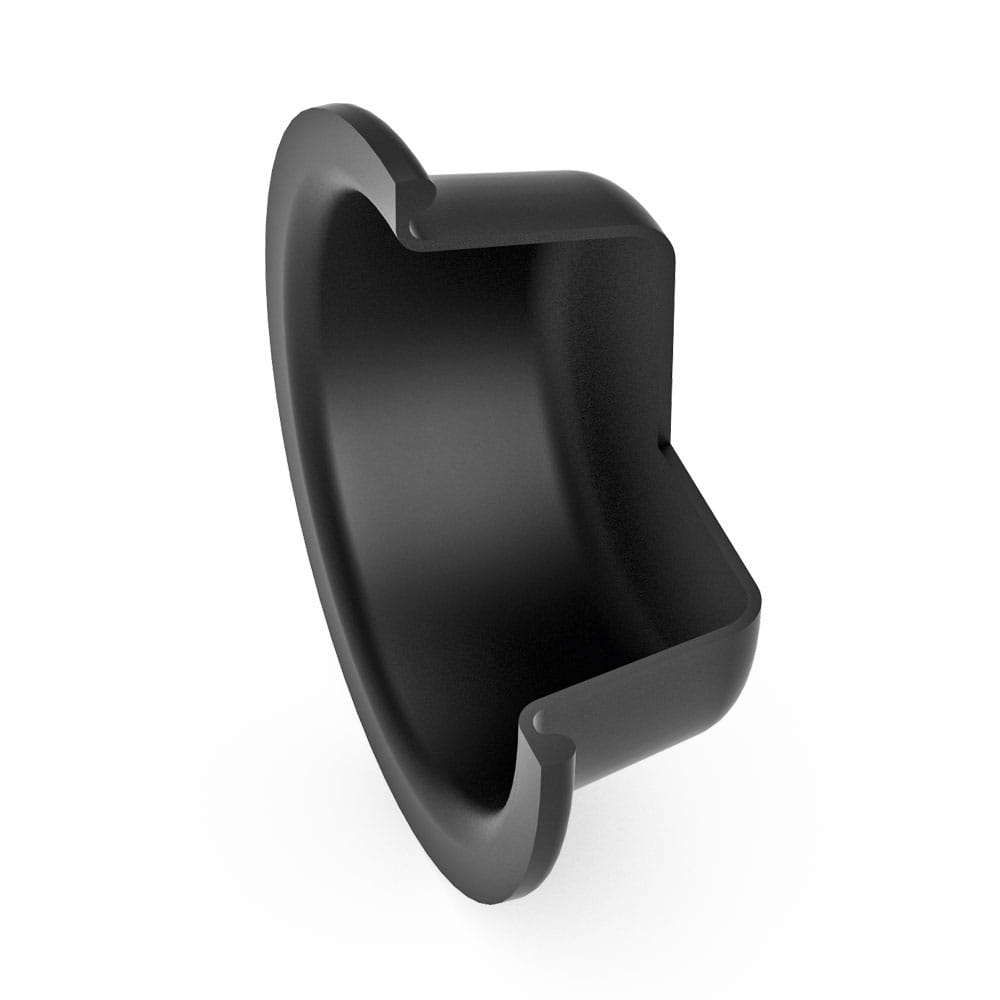

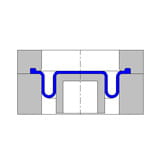

Convoluted Diaphragms

Dished Diaphragms

Rolling Diaphragms

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Related Topics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new