Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Of Batteries and Fuel Cells

Weinheim. As the head of the Battery & Fuel Cell Systems Division, Nils Martens is in the forefront of the transformative process at Freudenberg Sealing Technologies (FST) as the industry moves away from the internal combustion engine. In an interview he said he was very pleased with the response from FST’s customers and with the division’s rapid growth. He outlined an optimistic vision of the future.

Mr. Martens, please clear up an oft-heard misconception: Will FST be building car batteries in the future?

No. From a strategic standpoint, we have positioned ourselves quite clearly. The Battery & Fuel Cell Systems Division is focused exclusively on the heavy-duty market. That means trucks and delivery vehicles, buses, rail transport, ships and vehicles used in mining and construction. We offer these markets complete system solutions: battery systems, fuel cell systems with “balance-of-plant”* components or – in one highly desirable scenario – integrated hybrid drive systems that combine the advantages of batteries and fuel cells. In the process, we rely on the company’s own components and a unique degree of vertical integration in production. Who else can go from the separator to the cell, and then all the way to the battery system – or from the membrane to the membrane electrode unit (MEA) and stack, and then to the fuel cell system? And design and develop the required electronics and software in-house?

And in cars?

FST will naturally have a major role in batteries and fuel cells for cars. We provide the auto industry with seals and innovative product solutions such as our new advanced heatshield and DIAvent®, our pressure equalization valve. That means we deliver components – and meet the requirements for the integration of various functions where necessary. Here we are talking about “components-plus.” We don’t supply complete systems to automakers. But we will benefit from our ever-growing systems expertise in heavy-duty applications and will be able to launch carefully targeted new developments.

Why did FST make this distinction?

There are many reasons for this. I’ll give you the most important ones. The technical requirements for performance and long-term reliability are significantly higher for heavy-duty vehicles than for cars. The total number of charging cycles, the operating times and the required service life are very different in the car segment and the heavy-duty segment. Just imagine how many hours a delivery vehicle for a parcel service puts in day after day. Its battery has to be recharged to 100 percent every day, and, after a decade in operation, it still has to perform at the same level as its first day on the road. Or think about the literally heavyweight tasks that powertrain systems in buses, trains, ships, farm equipment and construction vehicles have to handle. At FST, our expertise in technology and innovation has to handle this highly challenging task profile. It is a very challenging market niche with the highest possible requirements for which we are superbly equipped.

We currently see few competitors that can meet these requirements with our level of focus and the right solutions. In the auto business, by contrast, there are many more companies, including the OEMs, that is, the car manufacturers, that are entering the battery business themselves to some degree. Naturally, we are ready to help them as development partners and suppliers with our innovative components.

Electrification is coming faster than expected!

Let’s turn to FST’s battery and fuel cell business specifically for heavy-duty applications. How is it doing?

Extremely well. Powertrain electrification is advancing much more quickly than people had thought. We are now working with many major players in the sector and are surprised at how quickly things are moving and how great the demand is for our expertise. The customer response has been extremely positive. Our customers trust us, and they are relying on our capacity for innovation, quality, global presence and our long-term financial solidity. We would never have dreamed this would happen to this degree. The division’s growth will be in the triple-digit percent range in 2019. By year’s end, we assume the number of our battery systems on the road, rails and water will be in the significant triple-digit range.

To what do you attribute these successes?

The pressure to take action is growing. It is driven by global regulation and the parallel decline in the total cost of ownership for electric applications compared to classic combustion alternatives. Considering these factors, it is impossible to get around electrification for the transport of goods and people. The number of “zero emission” zones is even increasing in marine transport. Ships relying solely on internal combustion engines are no longer permitted to enter the zones. At the same time, as I mentioned, our customers have enormous trust in our expertise.

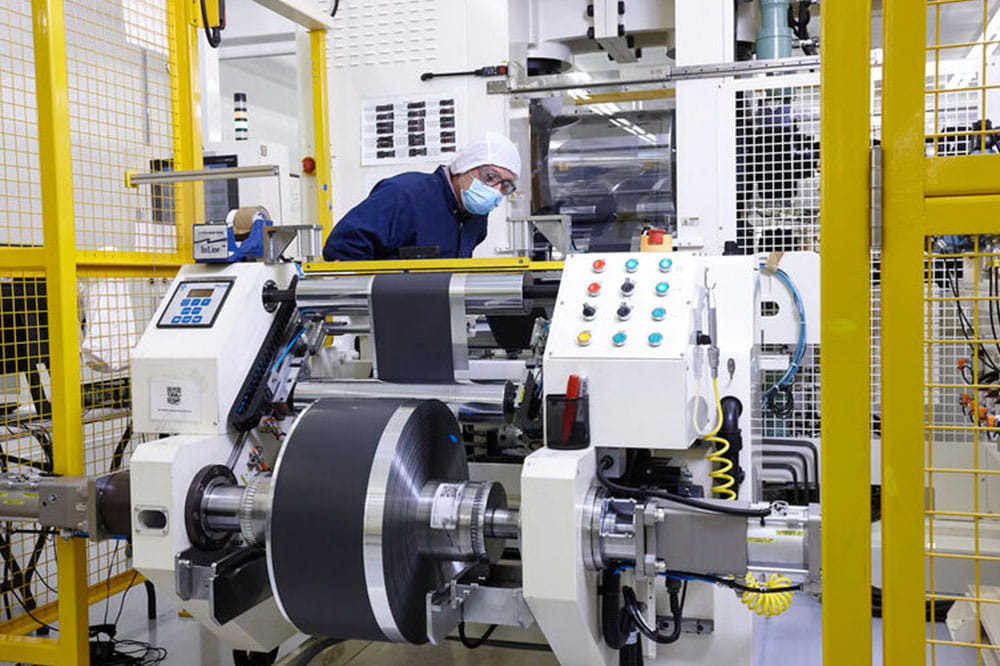

In the battery business, we have combined the unique technological expertise of XALT Energy with FST’s strengths, giving us a fully developed and validated battery solution that customers are already using. Our XALT Energy brand benefits from Freudenberg’s global presence and financial power – and from the strong contacts that we have with the market. We can simultaneously help XALT with the rapid expansion of its business and supply chain. As an example, I can point to FST’s long experience with Lean/GROWTTH and Six Sigma, which lead to operational excellence in manufacturing.

Let’s stay with XALT Energy for a moment. What makes the new FST brand so unique in the battery business?

For one thing, XALT products have extraordinary performance characteristics. One example: Lithium ion batteries from XALT Energy are known for their full-cycle stability at a market-leading level of energy density. Simply put, this means that their performance and service life are not impaired if they are charged all the way to 100 percent and discharged over and over again. In addition, XALT battery systems can be individually and precisely configured for each application through the use of modules. XALT’s vertical integration is deeper than that of any other supplier. A single source provides everything from the components in individual battery cells to the total battery system.

The portfolio also includes electronics, software and aftersales services such as installation, training and maintenance. Here telematics, the remote monitoring of batteries, is playing an increasingly important role. For example, telematics data can generate warnings or guidance on the operator’s driving behavior. These kinds of services and online options are increasingly becoming a component of our business model.

Now to wrap up our conversation: Where do fuel cells stand right now?

We see fuel cells in combination with batteries as an integral element of the mobility of the future. In integrated systems, batteries buffer the short-term demand for power needed during acceleration, for example, while the fuel cell handles the base load. Freudenberg has long experience with components for fuel cells and it has acquired additional valuable expertise through its acquisition of Elcore. We are going to bring our own fuel cell stacks to the market. The first tests of our prototypes are exceeding our expectations and are already meeting our customers’ requirements. The series production of this advanced technology is likely to begin in just a few years – in 2022 at the latest.

* Put simply, “balance of plant” describes all the components, modules and subsystems that are needed to use fuel cells.

** A marine integrator integrates the complete shipboard powertrain system, including electronics, engines, control systems, cooling, and so on.

In the current edition of our magazine ESSENTIAL, we report on topics around digitalization. Read more here.

More Stories About Digitalization