Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

31.10.2025 | News

Hydrogen As A Key Technology

Freudenberg Sealing Technologies expands the production capacity for hydrogen solutions at its Manchester site in New Hampshire, U.S.

Hydrogen is increasingly recognized as a key technology for a sustainable, clean energy future. This is also true in the USA. Through the Inflation Reduction Act, hydrogen projects have received funding aimed at creating a carbon-free power grid by 2035 and achieving net-zero greenhouse gas emissions by 2050.

Freudenberg Sealing Technologies also aims to benefit from this trend. As a leading provider of sealing technologies, the company operates production facilities at several sites in the USA and continues to expand its regional presence. Over the next few years, Freudenberg Sealing Technologies is investing tens of millions to increase production capacity at one of its largest U.S. locations – its site in Manchester, NH. This expansion has a clear objective: to boost the facility’s capacity for producing proper sealing solutions for the hydrogen market. This enables Freudenberg to strengthen the local supply chain and support the transition to renewable energy and carbon-neutral technologies.

Soeren Schmitz, Vice President of the Gasket Division at Freudenberg Sealing Technologies and Site Manager of the U.S. plant in Manchester, shares his views on hydrogen technology in the U.S. market.

What role does the hydrogen economy play in the USA?

Soeren Schmitz: Hydrogen is essential for decarbonizing various economic sectors. That is why we are seeing investments in hydrogen production capacities and infrastructure not only in Europe but also in the USA. The goal is to reduce dependency on fossil fuels and ensure the economic viability of hydrogen. In this process, it is important to consider the entire value chain of hydrogen. First the production, which in the USA is still primarily carried out by steam reforming of natural gas but will increasingly utilize water electrolysis in the future – i.e., splitting water into its components, hydrogen and oxygen. When the processing in hydrogen compressors, pump membranes or purification systems is finished, the hydrogen is transported to the points of use and stored in specialized tanks. In the end, it is used in various sectors, for example in transportation as an energy source for fuel cell vehicles or for maritime applications in container and cruise ships. Our company offers solutions for all these areas. In the USA, we are seeing that the electrolysis process – as the first step in the value chain – is still the most relevant option for our customers at this time.

How are you preparing for a potential increase in U.S. demand within the value chain you described?

Soeren Schmitz: Freudenberg Sealing Technologies continuously invests in research and development to provide our customers with added value. Our sealing materials that are specially formulated for hydrogen applications, for example, show exceptional media resistance, which contributes to the process reliability of electrolyzers. And last year we filed a global patent application for our innovative high-pressure hydrogen seals.

Thanks to our broad expertise, we can also respond quickly to market demands and customer wishes in the dynamic hydrogen sector. By investing in modern production technologies and automation, we are further strengthening our sites, increasing our responsiveness and securing jobs in the USA.

We pursue a “local-for-local” strategy, which involves local production and a close collaboration with our American customers. This reinforces the supply chain and reduces dependence on suppliers outside the USA.

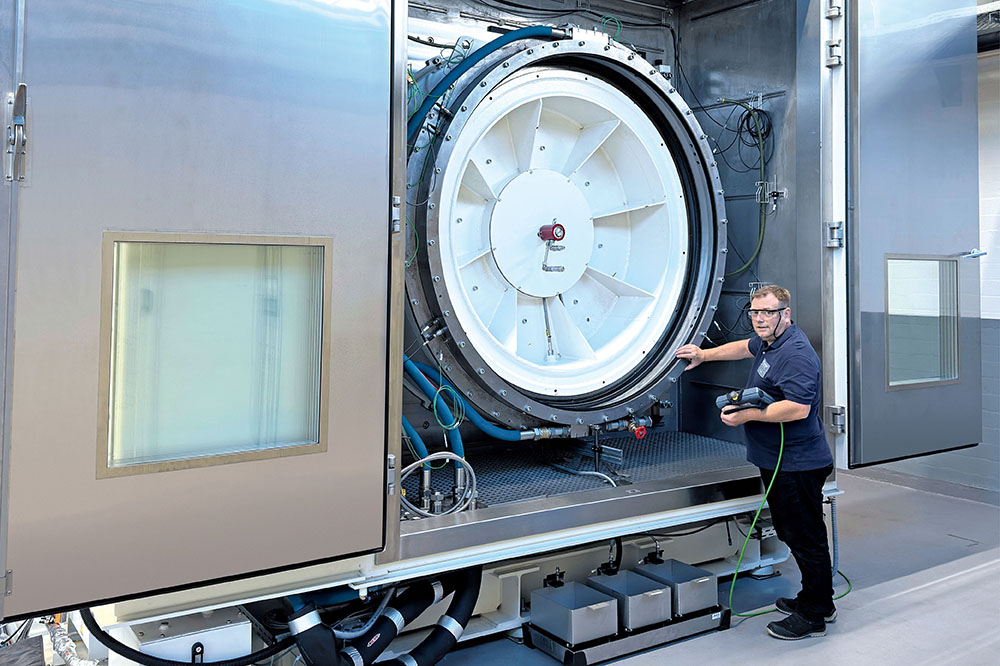

One example is our production site in Manchester, New Hampshire, which we are transforming into our key location for hydrogen applications. Until 2029, we will make substantial investments in production automation to increase manufacturing speed through new semi- and fully-automated production cells. We are investing not only in injection molding machines but also image processing systems and other testing systems – so we can guarantee both rapid delivery and superior product quality. We are gradually increasing our capacity, preserving jobs and potentially expanding them further. After all, even with automation, people are still indispensable so we can ensure the quality and reliability of our products.

What is special about sealing solutions for hydrogen applications?

Soeren Schmitz: We manufacture our highly specialized seals from our own material blends and tailor their design precisely to customer requirements. Let’s take electrolysis, for example. Sealing electrolyzer stacks is far from straightforward: The seals must prevent gas and electrolyte leaks while withstanding mechanical stress, temperature fluctuations and gas pressure changes. Electrolyzers operate under extreme chemical conditions, which pose significant challenges to the material. That is why media resistance is an essential requirement for durable sealing solutions. For use under these tough conditions, we offer precision-molded elastomer seals, seals on thermoplastic or metal frames and seals on bipolar plates. In electrolyzers, operating pressure can reach up to 60 bar, making sealing solutions particularly complex. We have developed a special high-pressure L-shaped seal for this purpose that transforms into a C-shape when the pressure increases, which ensures reliable sealing. Besides the right material, an innovative design is also crucial for a successful high-tech sealing solution.

Focus on Green Hydrogen

Freudenberg Sealing Technologies is especially zeroing in on electrolysis processes that can be used to produce green hydrogen: the anion exchange membrane (AEM) and proton exchange membrane (PEM) electrolysis. Either can be ramped up or down quickly, making them a practical option to use with inconsistent sources of renewable energy such as wind and solar power.

You can find more information on products for the hydrogen industry here:

The Future is Hydrogen open_in_newMore news on the subject Renewable Energies

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.