Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

04.09.2025 | Press release

Sustainable and Standards-compliant: Seals for the Beverage Industry

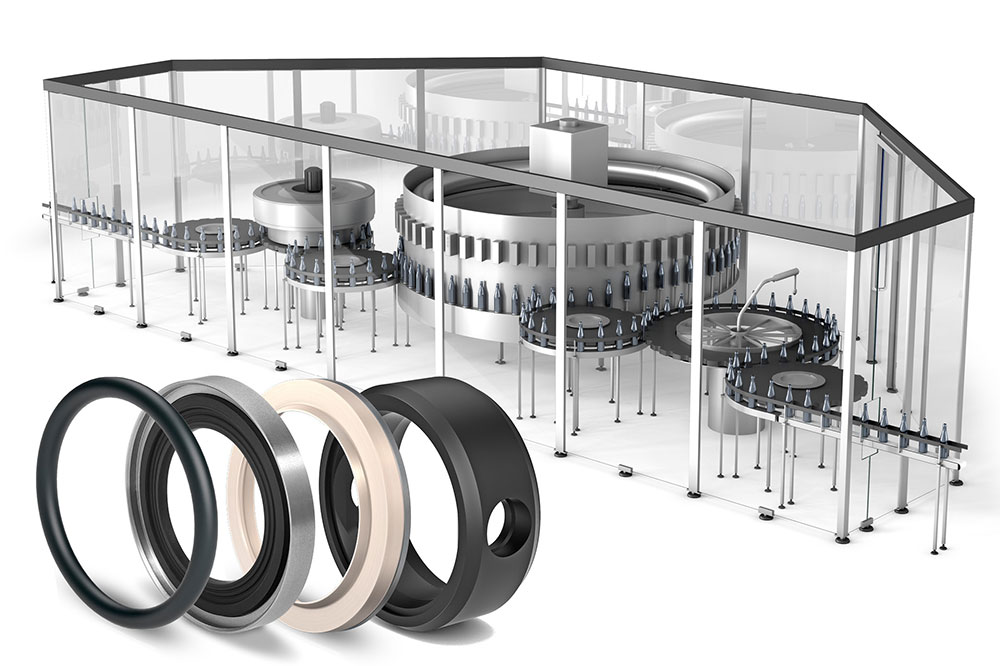

Weinheim, September 4, 2025 - From September 15 to 19, 2025, the leading global trade fair for the beverage and liquid food industry offers plenty of space for active networking and a review of trends in the food and beverage industry. At Stand 348 in Hall B5, Freudenberg Sealing Technologies is presenting a high-performance clamp seal in a hygienic design, along with industry-specific sealing materials. For the first time, a simplified process for the rapid replacement of shaft seal rings will also be introduced to professionals attending the fair in Munich. The company is showcasing optimizations of proven seals that are geared to the future. Attendees get the chance to work with seal models in a test setting and install them on their own at the stand.

Clamp seal with support ring: sustainable sealing system for flange connections

Freudenberg Sealing Technologies has developed a reliable, hygienic solution for clamp connections that enables the gap-free sealing of tube systems using local, media-based compression of the elastomer seal. With this development, Freudenberg Sealing Technologies experts were thinking a step ahead. The hygienic clamp seal is provided with a metallic outer ring as a limit on compression – and the support ring can be reused. This makes it possible to conserve valuable resources such as materials and energy while avoiding waste. The clamp seals were developed in accordance with DIN 32676 and can be produced for various tube diameters. They also lend themselves to retrofit solutions for existing tube systems thanks to their backwards compatibility.

Hands-on and heads-up: See how high-performance seals work

When it comes to new technologies, performance matters and hands-on testing is a great help. At the Freudenberg Sealing Technologies stand, attendees can perform a test to see how easily seals can be swapped during the maintenance cycle. Aside from the haptic testing of new seal solutions, the test stand features an important visual feature as well: A demonstrator shows the functioning of the seals, depicting what happens when non-hygienic or improperly placed seals jut in or out and disrupt the flow of the medium inside the tubes. The result is contamination. The demonstration reveals excellent material performance, but that is just one aspect of the company’s presence at drinktec. Another focus is the exceptional functioning of the components that are used.

SmartChange system: Saving time and avoiding waste when changing seals

Freudenberg Sealing Technologies is setting new standards in the food and beverage industry with a newly developed clamping ring for the extremely quick and easy installation and removal of shaft seals in the Radiamatic® HTS II series. Thanks to smart design development, a complete dismantling and mounting cycle can be carried out in just a few minutes. The specially adapted geometry of the clamping ring provides a secure fit for the seal in the installation space while allowing the effortless removal of the high-performance sealing element. Another advantage: The clamping ring stays in the installation space and does not have to be replaced. The installation of a profile ring afterwards is straightforward. The starter kit includes a new clamping ring as well as a profile ring from the Radiamatic® HTS II portfolio. All the single- and double-lip variants of the HTS II series are available with the new SmartChange system – including the hygienic design version with a forward-positioned lip. Cleaning is easy with conventional CIP and SIP processes.

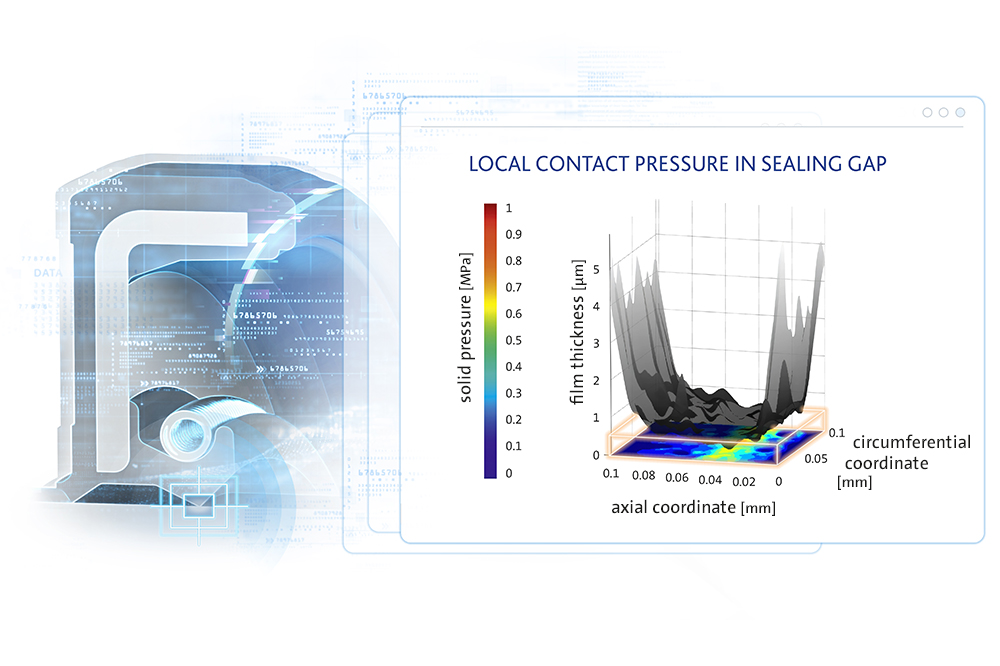

High-performance materials: Optimal seal design boosts process efficiency

Superb material knowhow and maximum manufacturing precision are needed to fulfil national and international guidelines and standards in the food and beverage industry. Freudenberg Sealing Technologies’ experts offer both. At drinktec, the company is introducing a newly developed sealing material – the “75 HNBR 641” – that meets FDA and EU 1935/2004 requirements. The long-lasting seals are much more robust than conventional HNBR compounds. In addition to exceptional mechanical performance, they exhibit maximum abrasion resistance even under dynamic stresses. That makes them ideal for hygienic applications. As it develops new production processes, the Weinheim-based company is increasingly seeking optimized resource efficiency, and it passes the benefits on to its customers, such as a longer service life or reduced material use due to recycling. Michael Littig, Senior Sales Director Europe at Freudenberg Sealing Technologies, is eager to see which sealing topics will be in high demand at drinktec this year. “The concentrated expertise of Freudenberg Sealing Technologies is on display at drinktec, and we are looking forward to discussing specific requirements and expanding our existing networks,” he said.

Josh Barnett

Corporate Communications Manager

Telephone: + 1 734 354 2406

josh.barnett@fnst.com chevron_rightMichelle Klöss

Senior Manager Communications

Telephone: + 49 (0) 6201 960 5379

michelle.kloess@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.