Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

17.09.2025 | Press release

Large-Ring Test Bench Sets New Standards in Sealing Technology

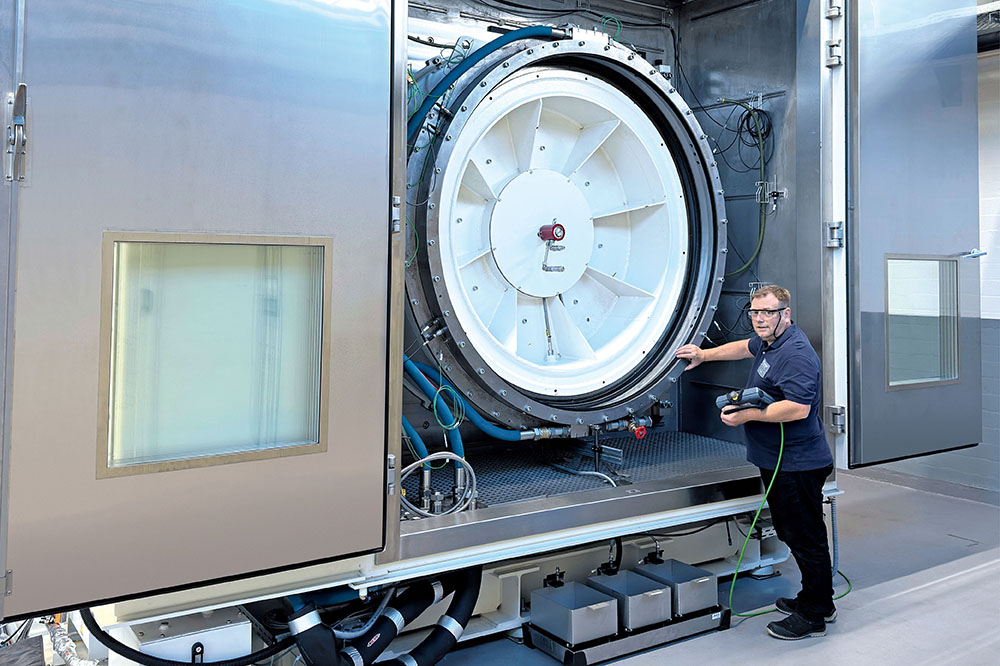

Weinheim (Germany), September 17, 2025 – With its newly designed large-ring test bench for shaft seals, Freudenberg Sealing Technologies is strengthening its position as an innovation leader in the development and validation of high-performance seals for wind turbines, tunnel boring machines, and other heavy industry applications.

Seals in these sectors face extreme demands: harsh environmental conditions, high mechanical loads, and long service life. The wind energy industry, in particular, is evolving rapidly—with ever-larger turbines and increasingly complex challenges.

“To maintain our leadership in main bearing seals for wind turbines, we need testing processes that can reliably replicate real operating conditions and accelerate validation,” explains Jens Kuhnert, Business Development Manager at Freudenberg Sealing Technologies in Hamburg. “Our new large-ring test bench delivers exactly that.”

Technical Highlights and Capabilities

The test bench weighs approximately 56 tons, measures about 9 x 7 x 4 meters, and accommodates seals with diameters ranging from 1,000 to 2,000 millimeters. For the first time, up to four large seals can be mounted simultaneously and supplied via two separate oil circuits. A specially developed module makes it possible to set a dynamic eccentricity of up to ±10 millimeters, simulating what happens when the axle is not exactly centered due to high loads. This is important, for example, when testing main bearing seals in wind turbines under realistic conditions. The integrated climate chamber covers a temperature range from -30 to +120 °C. Pressure testing is possible up to 15 bar. Resistance tests against moisture, dust, and dirt particles are also part of the protocol. All parameters can be individually adjusted, either manually or automatically.

Comprehensive Testing Strategy as a Key Driver

Commissioning the large-ring test bench is a key element of a comprehensive testing strategy at the Hamburg site. This is complemented by external testing capacities and on-site testing at customer facilities.

Digitalization plays a crucial role: it makes testing processes more efficient and transparent while channeling the data generated by each measurement. In the future, results will feed into simulation models and digital twins, for example, to analyze disturbances or aging effects. This enables faster iteration and validation of seal designs—accelerating agile development of high-quality seals and providing customers with a decisive advantage: maximum functional reliability when launching their high-performance systems.

Customer Intimacy Through Co-Development

Freudenberg Sealing Technologies aims to work closely with customers from the early stages of technology and system development. This ensures that materials and sealing concepts are precisely tailored to specific requirements.

“With the new large-ring test bench, we are intensifying collaboration with our customers,” Kuhnert says. “We’re moving even closer together – for faster development cycles and sustainable solutions.“

Josh Barnett

Corporate Communications Manager

Telephone: + 1 734 354 2406

josh.barnett@fnst.com chevron_rightIsolde Grabenauer

Senior Director Communications & PR

Telephone: +49 (0) 6201 960 7467

isolde.grabenauer@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Renewable Energies

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.