Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

29.03.2022 | Press release

Zeroing In On Defects

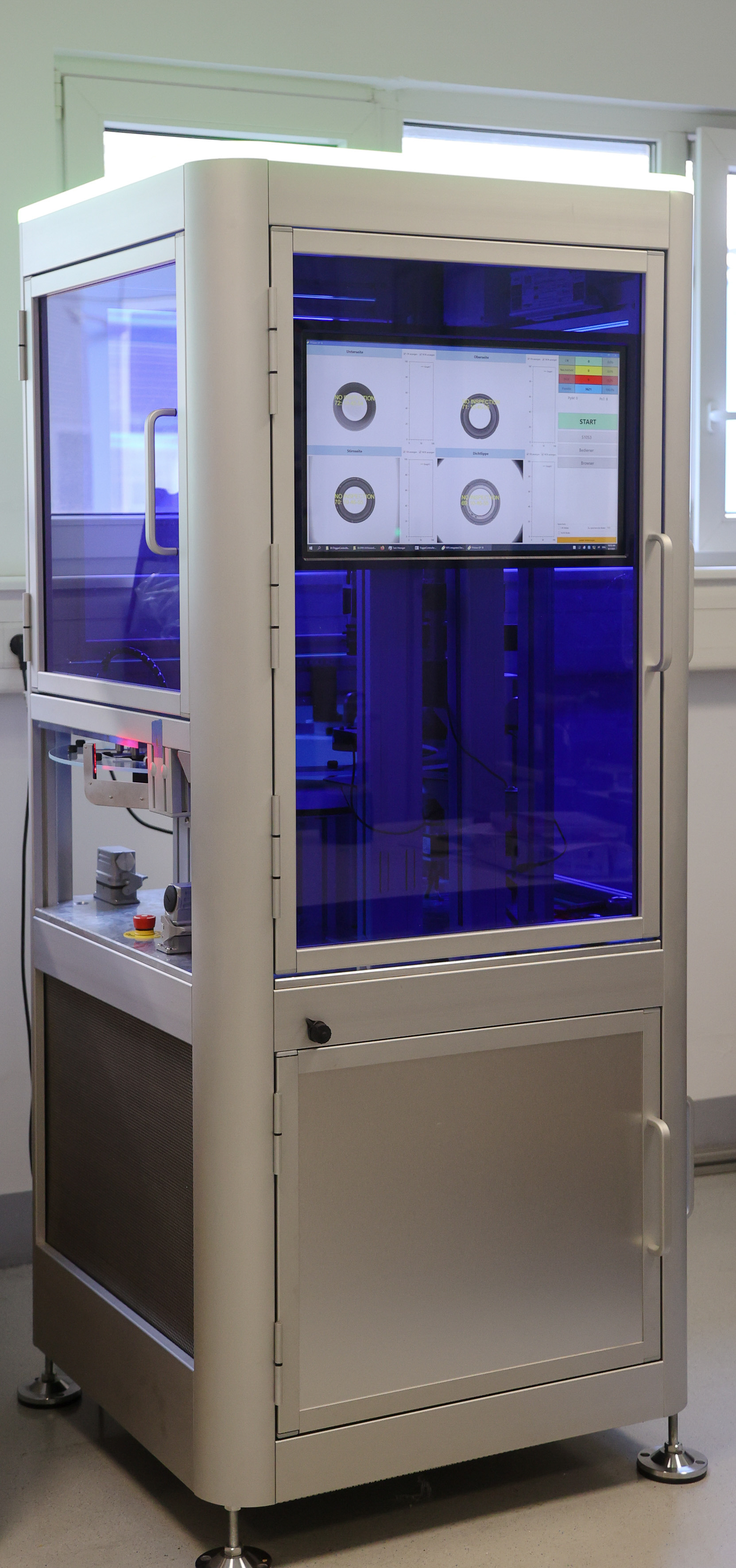

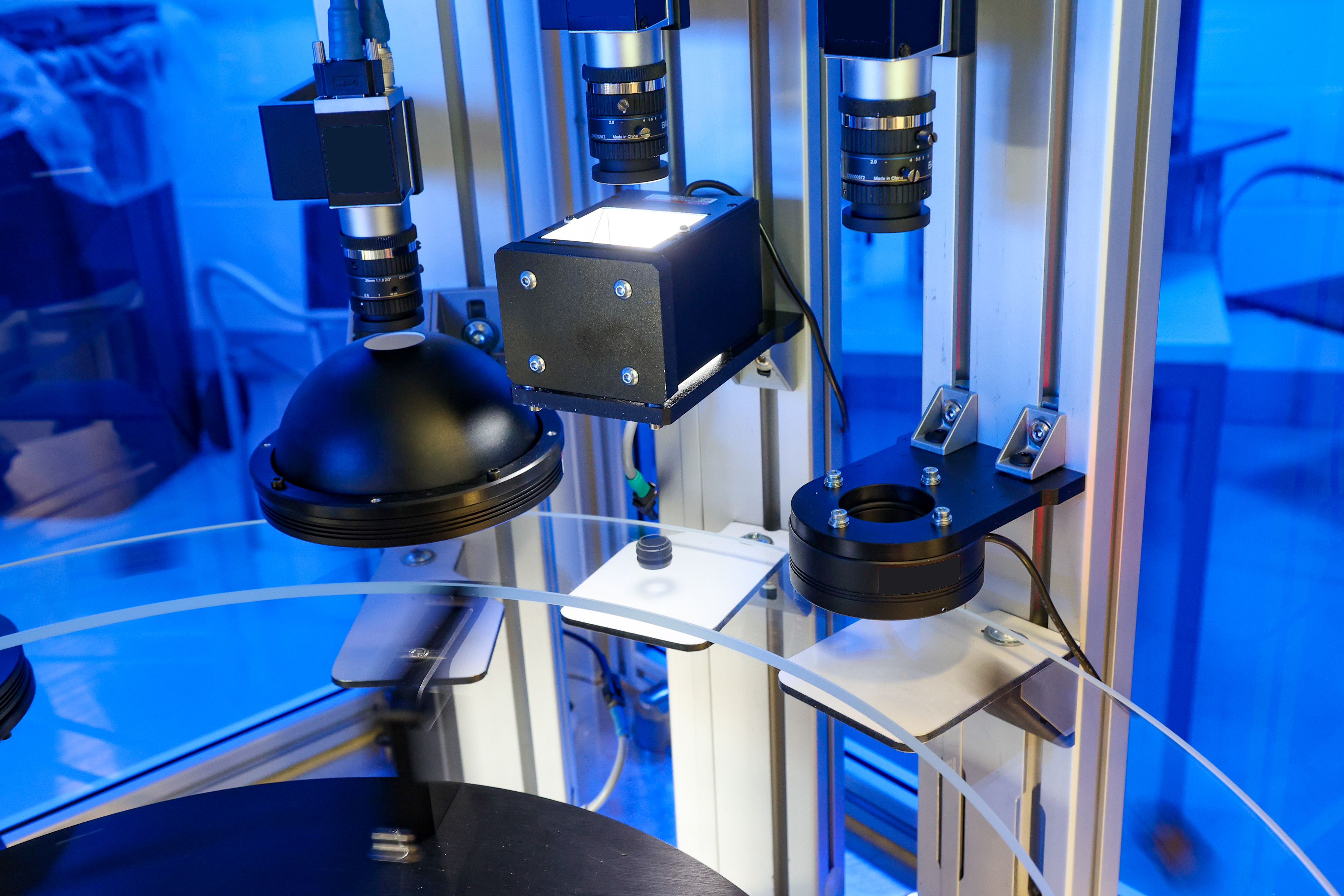

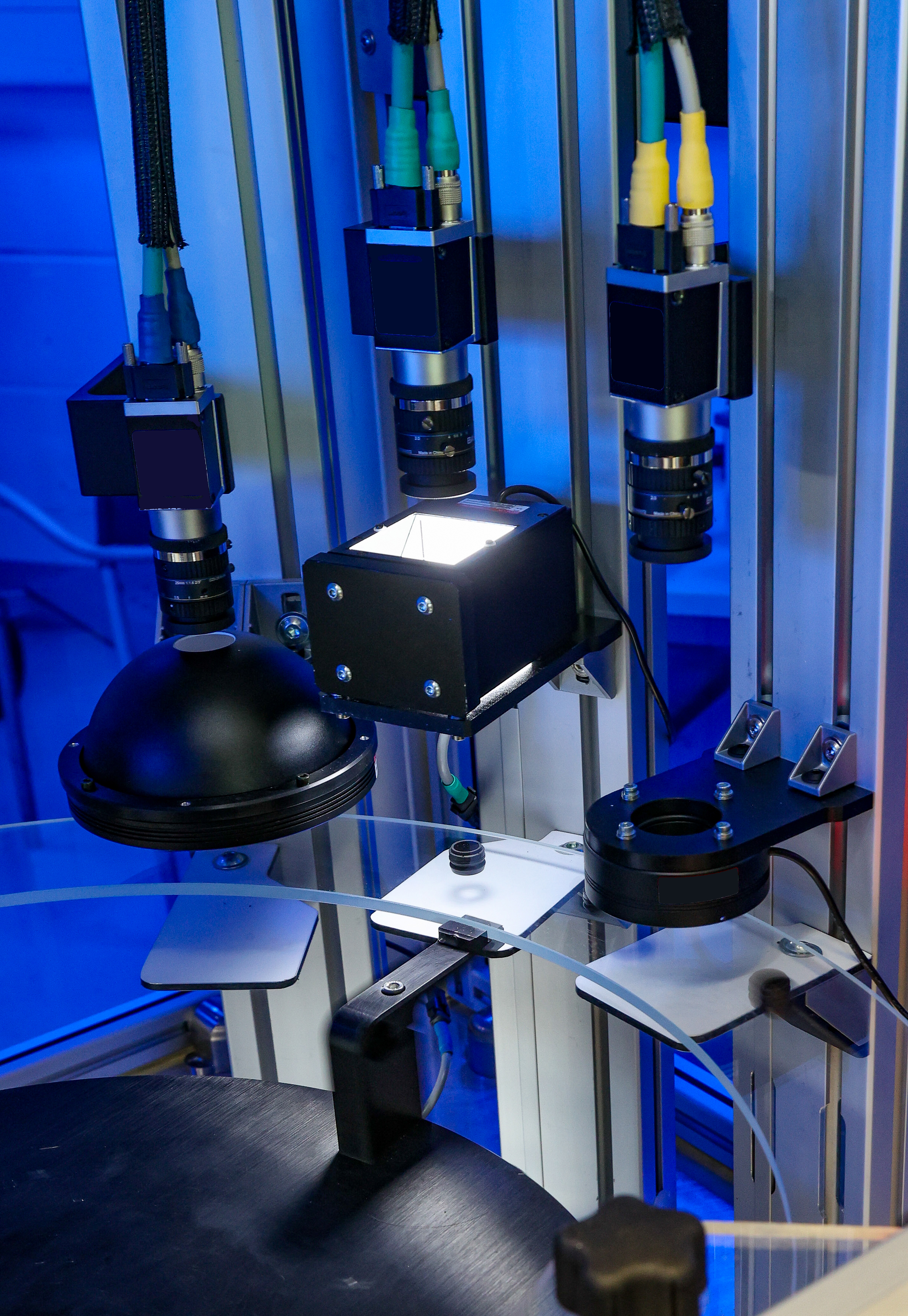

Weinheim (Germany), March 29, 2022. Freudenberg Sealing Technologies is stepping up its own zero-defect, quality efforts with the installation of a next-generation, advanced machine vision inspection system. The system combines proprietary vision control technology with advanced automation, thus eliminating some process steps involved in quality inspections on small parts. Developed and built by company engineers, the machines are smaller, more flexible and efficient and less expensive to build than commercially available inspection units.

The first rotary, glass plate FVision GP 50 device, which was developed by Freudenberg engineers in Germany and the U.S., was installed in the company’s Morristown, Ind., facility in early January. The plant has ordered additional units for installation in 2022, and other sites of Freudenberg Sealing Technologies like Oehringen, Oberwihl and Weinheim, Germany and Bristol N.H. are in discussion about installing the new technology.

Developing the FVision GP 50 technology internally has enabled Freudenberg Sealing Technologies to tailor individual inspection machines to specific production applications and defect parameters, explained Robert Scavuzzo, Vice President of Freudenberg’s Global Advanced Manufacturing Technology group. The automated system also minimizes the need for manual inspections, which typically take more time and are less likely to detect tiny defects.

“We’re constantly looking for ways to improve our production processes,” Scavuzzo said. “The updated machine vision technology is the next step in the evolution, helping us to more effectively meet zero-defect mandates, while providing clear benefits to our customers and end users.”

Small, Fast and Flexible

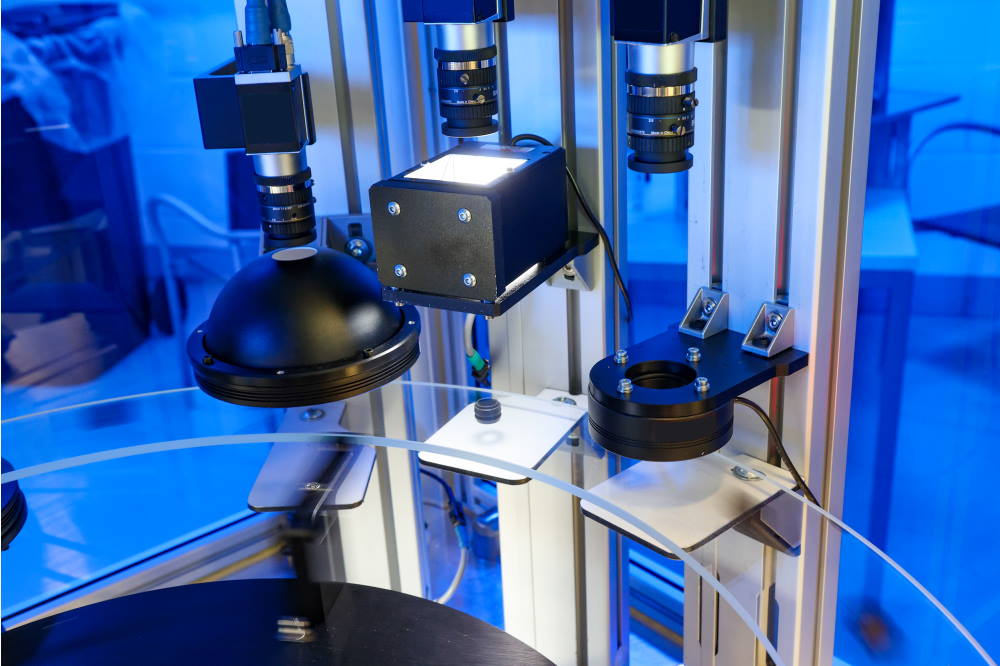

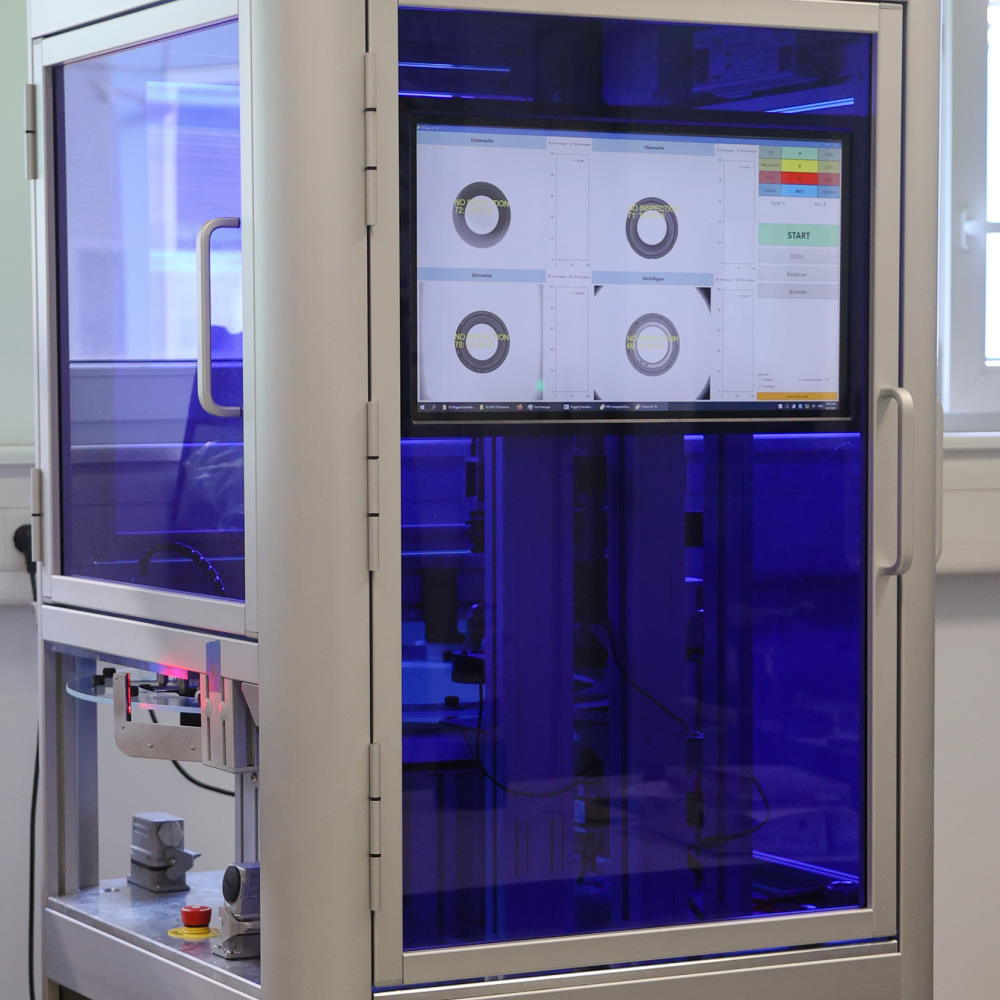

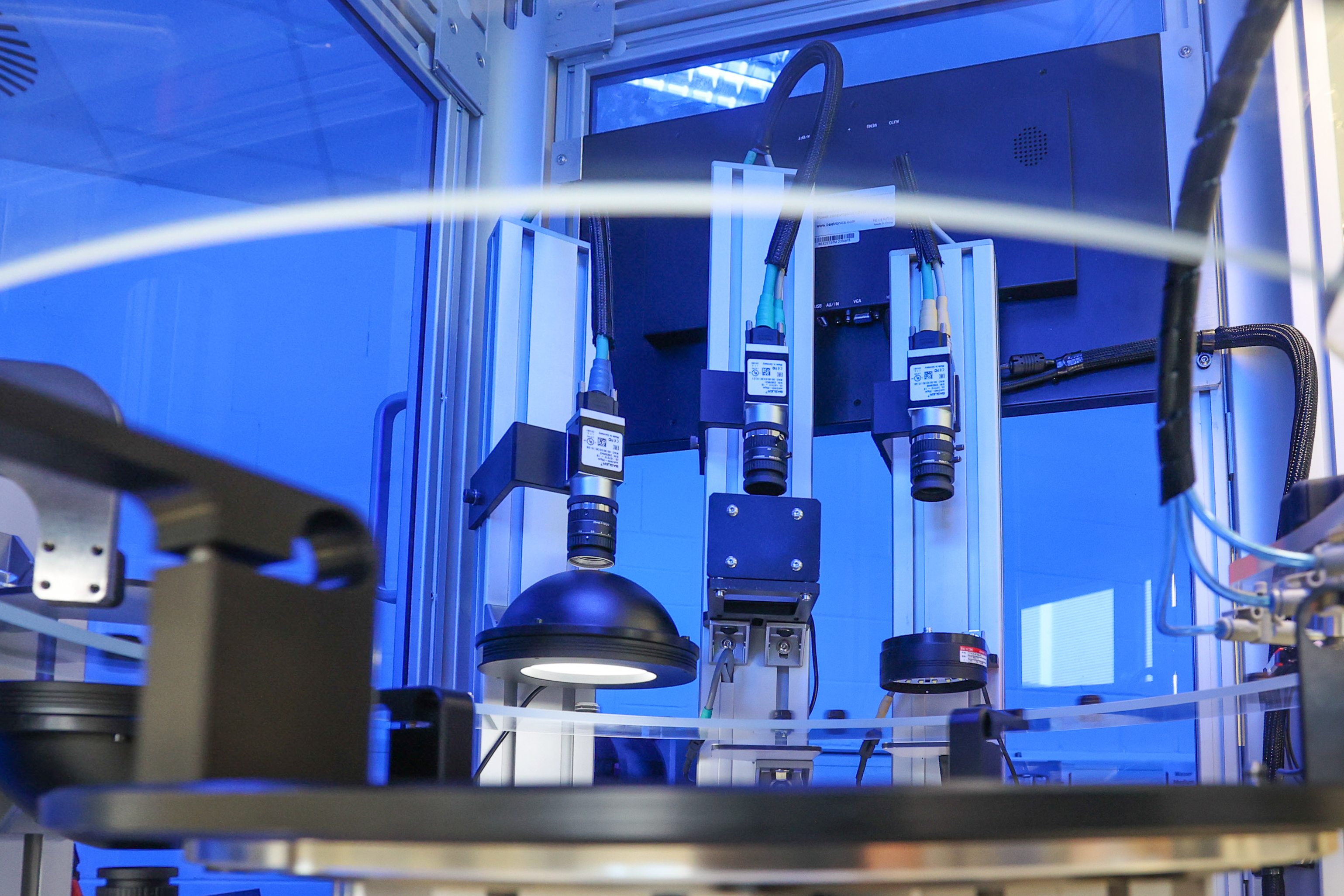

The FVision GP 50 machine can be used to inspect a wide variety of components, including small automotive seals, springs and O-rings, made of different types of materials and with different production processes. It features new image processing technology – including the ability to self-adapt to process variations – and can support as many as four cameras.

Measuring just 80 cm by 80 cm (not including feeder and packaging components), the streamlined unit is about one-third the size and cost of current glass-plated inspection machines. The machine is stationed at the end of a production line or process to measure variances in parts as they are completed. It can inspect up to 10 parts per second, although feeding rate limitations will likely result in some throughput variation among production applications.

Each new part is compared with hundreds of previously approved parts to detect differences, as well as distinguishing between actual defects and random process variations such as those caused by dirt or dust. The initial application is designed to conduct about 20 different surface inspections. Additional surface inspections and/or adherence to dimensional tolerances can be added as needed.

Most defects appear during the molding process as a result of material damage within the mold. Other potential problems can occur during finishing operations, such as in trimming to remove excess rubber flash.

Significantly, the FVision GP 50 inspection units will reduce the possibility of expensive customer recalls through a more robust production inspection process. The units will identify defective parts and reject them. They will also categorize and visually record the defects and produce visual alarms when too many are detected, making it possible for machine operators to access this data and apply it upstream to permanently eliminate defects from the injection process.

The data can be transferred between inspection units operating at any Freudenberg manufacturing site, creating a communication network dedicated to the elimination of product defects and the improvement in quality results.

The Big Picture

FVision GP 50 is part of Freudenberg’s efforts to standardize equipment and processes throughout its production facilities. To this end, Scavuzzo estimates that the new inspection machine could eventually be used in about 80 percent of Freudenberg’s Sealing Technologies manufacturing plants with minimal design changes, while the camera, illumination and software would be customized for specific applications.

The system also supports “Industry 4.0” initiatives and the trend toward increasing automation on the plant floor.

“Most FST vision control machines are connected to some sort of database, producing live status information about the process and machine conditions,” explained Dr. Helmut Hamfeld, Senior Engineering Specialist in Advanced Manufacturing Technology for Freudenberg Sealing Technologies. The integrated system notifies operators of incidents, he said, and, in some cases, such feedback can be immediately applied to correct problems or improve efficiencies during a running process.

The ultimate goal for the FVision GP 50 technology is to create a real-time communications network between the units and Freudenberg’s injection molding machines that will stop the injection process as soon as too many defects are detected. Misalignments and other issues can be addressed immediately by operators, dramatically increasing the company’s ability to eliminate production of defective components in the first place. “There is no room for product defects,” he concluded. “Customers want perfect parts every time. Our new machine vision inspection technology makes such demanding requirements easier and considerably less expensive to achieve.”

Press Release Downloads

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.