Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

10.11.2021 | Press release

Climate-Neutral Travel

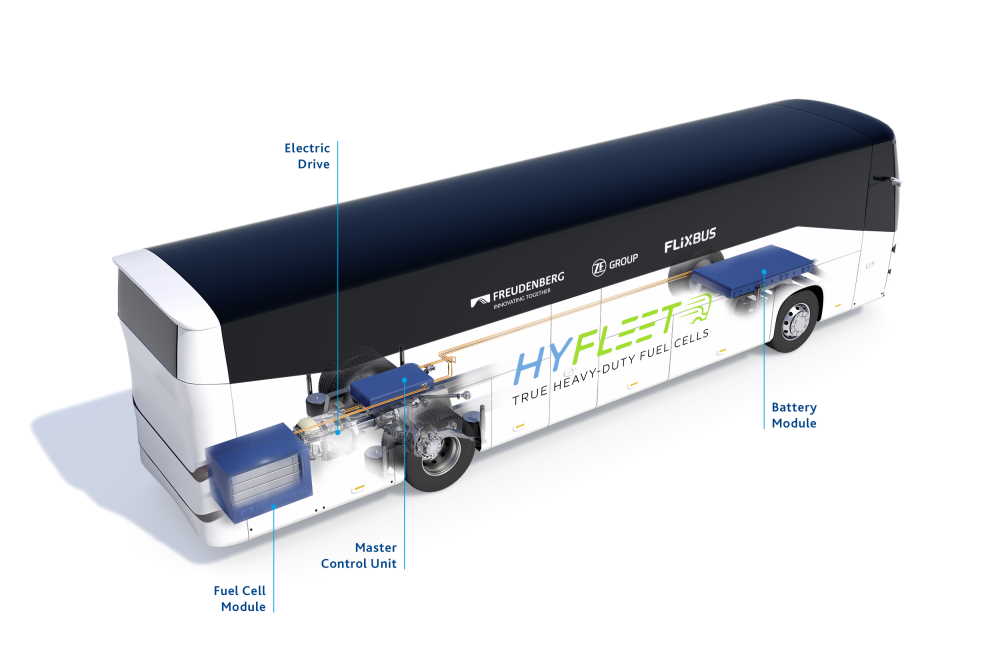

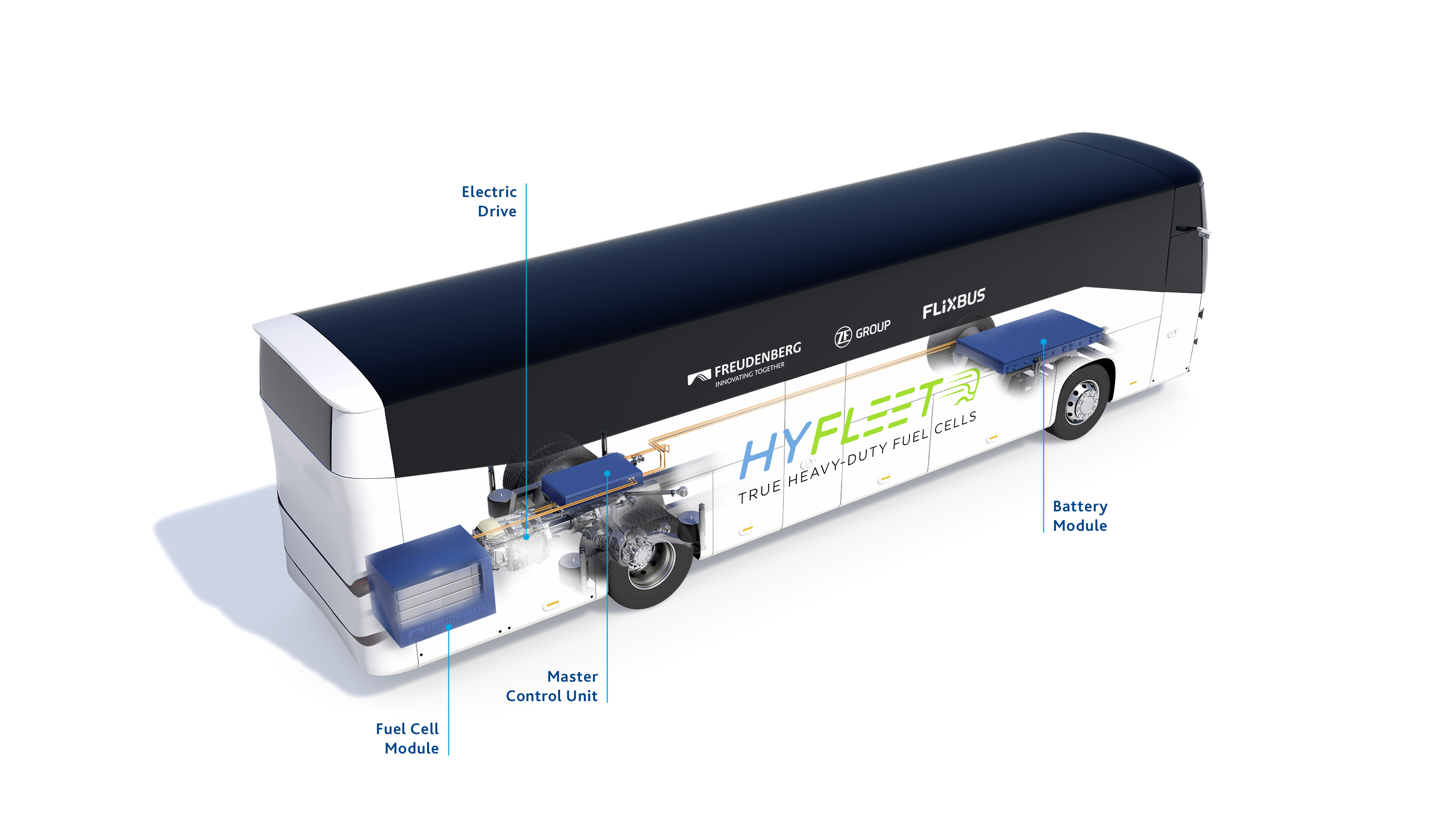

Weinheim/Munich (Germany), November 10, 2021. Technology supplier Freudenberg is starting the research project “HyFleet” together with ZF Friedrichshafen and FlixBus. The partners aim to jointly develop a high-performance fuel cell system until 2024 to completely replace conventional diesel drives. They will also be examining the hybridization of electric powertrains with fuel cells and batteries.

Anyone traveling by long-distance coach instead of using a car already reduces CO2 emissions by 6.6 kilograms on a 400-kilometer (249 miles) trip. However, to date there has been no practical solution for completely carbon-neutral operations of long-distance bus fleets in regular service. The reason is that long-distance services are extremely demanding to operate: Just like long-distance freight trucks, buses are often used day and night and travel well over 100,000 kilometers (60,000 miles) per year. The durations of stopovers must be minimized in the interest of the passengers. And the long charging times for the batteries of purely battery-electric drives as well as the implementation of the cost-intensive charging infrastructure this requires are simply not feasible in this sector.

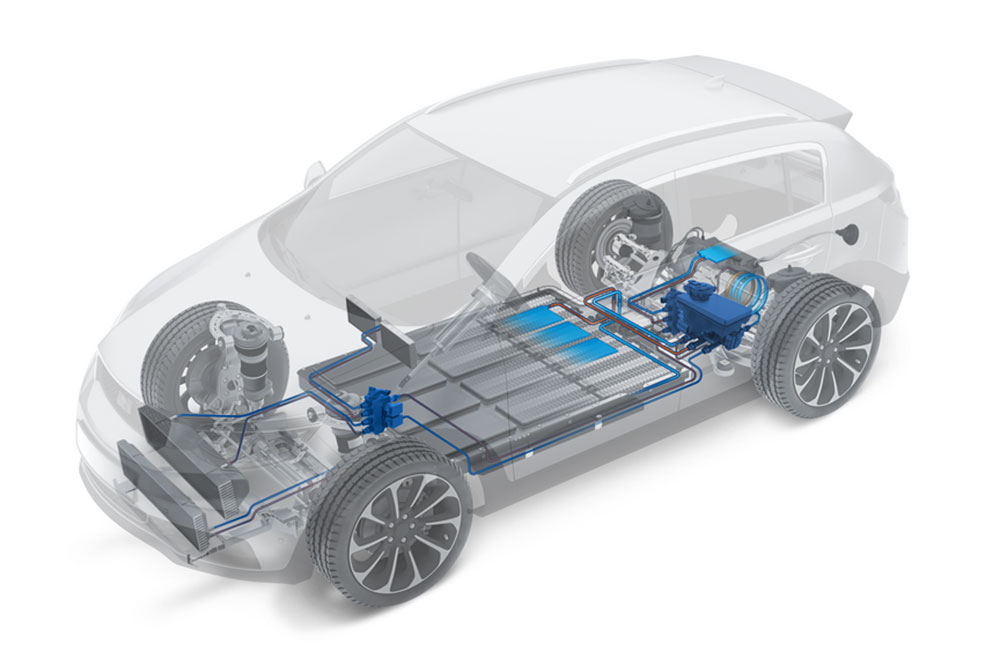

Hydrogen-powered fuel cells that are combined with an electric drive and complementary battery storage to form a hybrid powertrain could be an alternative. Such a solution will now be explored as part of a major fuel cell technology project. A powerful consortium of leading industry players consisting of Freudenberg, ZF, FlixBus and a major European bus manufacturer has joined forces for this purpose. The German Federal Ministry of Transport and Digital Infrastructure has already provided a non-binding letter of intent for funding the project.

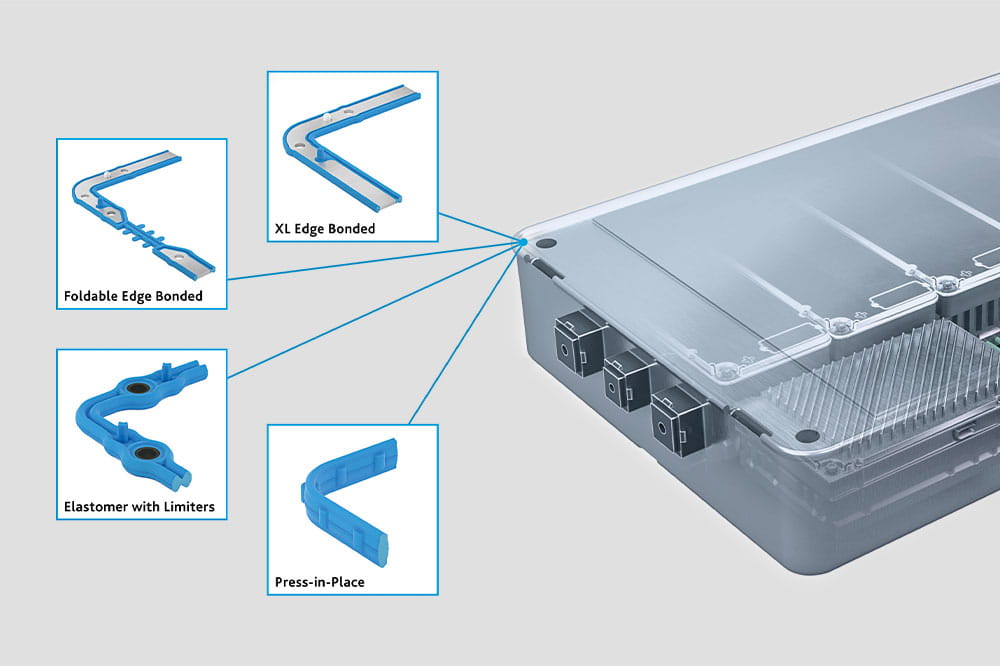

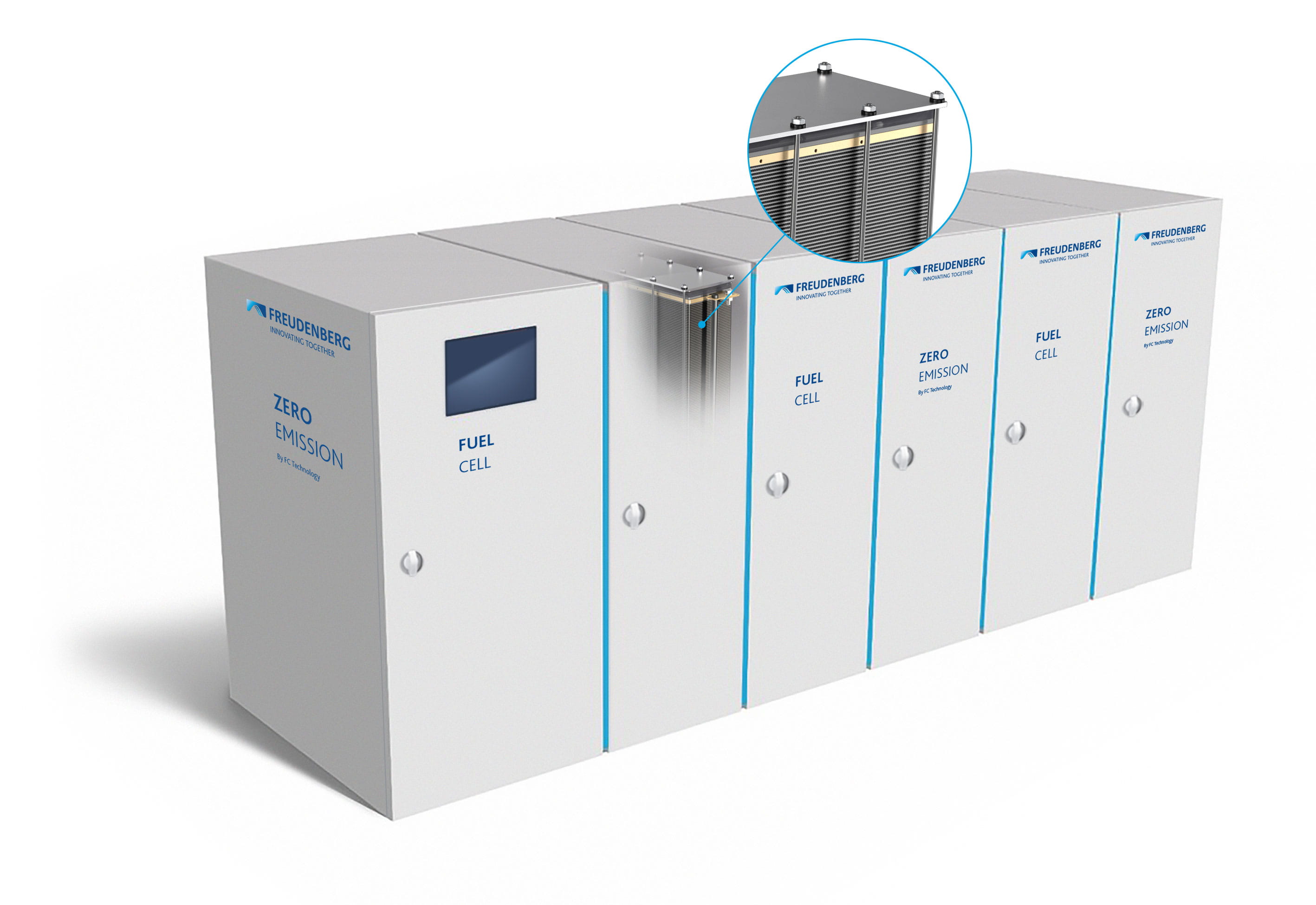

Within the project called “HyFleet”, Freudenberg is developing a long-range fuel cell system that will be tested directly in a demonstrator long-distance bus. “Freudenberg will contribute decades of fuel cell expertise on component and system level to the project,” explains Claus Möhlenkamp, President and CEO of Freudenberg Sealing Technologies. “We aim to significantly advance the long-term durability and efficiency of the technology and set standards for the total cost of ownership.” The project will also focus on hybridization strategies for powertrains, the so-called right-sizing between fuel cells and batteries.

Competent Partners

By researching hybrid fuel cell systems together with the project partner ZF Friedrichshafen, Freudenberg is working on an innovative issue that is highly relevant for all heavy-duty segments. “ZF’s broad technology portfolio and expertise on electrified powertrains and associated systems are already making it easier for vehicle manufacturers to get started in e-mobility. With their range and fast refueling times, fuel cells will play an important role in e-mobility for heavy commercial vehicles in the future,” says Wilhelm Rehm, member of the ZF Board of Management responsible for Commercial Vehicle Technology and Control Systems. “We have always had an open-minded approach to electrification technology – from the very beginning, fuel cells have also played an important role for us as a drive solution.”

To ensure that the fuel cell system can withstand the rigors of practical operation in long-distance buses, the first stage of the HyFleet project will center on the fuel cell’s technical performance. Among other things, this includes optimizing the behavior of the fuel cell system in continuous use with a minimum operating time of 35,000 hours. This means that the degradation mechanisms must be controlled, thus maximizing the system’s efficiency over the entire service life. Fleet operators will notice low fuel consumption as a result. At the end of the project, Freudenberg’s innovative fuel cell system will be tested in a demonstrator bus provided by the bus manufacturer.

The partner FlixBus contributes the expertise of a global mobility provider to the project. With the constant improvement of alternative drives and sustainable travel alternatives, FlixMobility is playing a key role in the shift to green mobility, explains André Schwämmlein, co-founder and CEO of FlixMobility. Together with over 500 partner companies, the business is already operating Europe’s largest fleet with more than 4,000 long-distance buses in regular service. “Fuel cell technology will make an important contribution to the drive train technology shift in mobility. And it gives bus manufacturers, for example, the opportunity to actively help shape the future of travel. We are proud to be part of the HyFleet project to develop the first fuel cell-powered long-distance bus in Europe until 2024 together with Freudenberg and ZF,” adds Schwämmlein.

The non-profit organization atmosfair is calculating the amount of the CO2 reductions of a FlixBus hydrogen fleet achieved due to the innovative fuel cell technology across the entire energy chain, including hydrogen production and distribution.

Sending a Message

Even if HyFleet is focusing on coach fleets, one of the project partners’ priorities from the outset is that the achieved results can be transferred to all heavy-duty segments, especially to freight transport with heavy trucks. Freudenberg also believes that coaches could play a pioneering role in the rapid switch to hydrogen mobility – because thanks to the long-distance buses, the refueling infrastructure created along the most heavily traveled highways would be reliably used to capacity. “We need pragmatic, climate-neutral drive solutions for long-distance freight transport,” says Claus Möhlenkamp. “Our fuel cell systems provide such a solution. Together with our partners, such as ZF Friedrichshafen and FlixBus, we are now developing the scientific basis for rapid industrialization and upscaling of the technology.”

In addition to the HyFleet project, ZF Friedrichshafen and Freudenberg are jointly researching additional applications to develop fuel cell solutions for mobility applications and industrial use.

Since 2018, Freudenberg has already launched various cooperation projects with renowned partners to develop fuel cell systems for the heavy-duty sector. Among other things, the company is a technology partner in the “Pa-X-ell2” project. The goal is to develop a new generation of fuel cells to be used for passenger ships on the open seas. In addition to Meyer Werft, the project consortium includes Lürssen Werft, the classification society DNV GL, the German Aerospace Center, AIDA Cruises represented by Carnival Maritime GmbH, besecke and EPEA GmbH.

Press Release Downloads

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_right

Freudenberg Fuel Cell Technology Products

True Heavy-Duty Fuel Cell Systems for Carbon-Neutral Mobility

Read more open_in_newMore news on the subject Automotive & Transportation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.