Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

15.01.2018 | Press release

Meeting the Unique Challenges of the Automotive Industry’s E-Mobility Era

Detroit (USA), Jan. 15, 2018. For the second year in a row, visitors attending the North American International Auto Show in Detroit will be able to experience some of the newest developments in Mobility and E-Mobility at the Automobili-D exposition at Cobo Center. The event offers confirmation that groundbreaking changes are taking place in the automotive industry, and as advanced electric vehicle systems gain traction, Freudenberg Sealing Technologies – a long-term sealing specialist to the global industry – is working to meet current customer needs while also preparing for what the future may hold.

Although both the internal combustion engine and electrified powertrains are expected to grow, Freudenberg is planning on electric vehicles reaching significant volumes by 2025 and beyond. This means that automakers and suppliers are already getting immersed in the product and solution needs specific to E-Mobility advancement.

“Our current focus is two-fold,” said Claus Möhlenkamp, CEO of Freudenberg Sealing Technologies. “We want to help make internal combustion engines more efficient with our solutions, but dually, we are channeling a serious amount of focus into developing components for the new powertrain technologies that will shape the mobility of the future.”

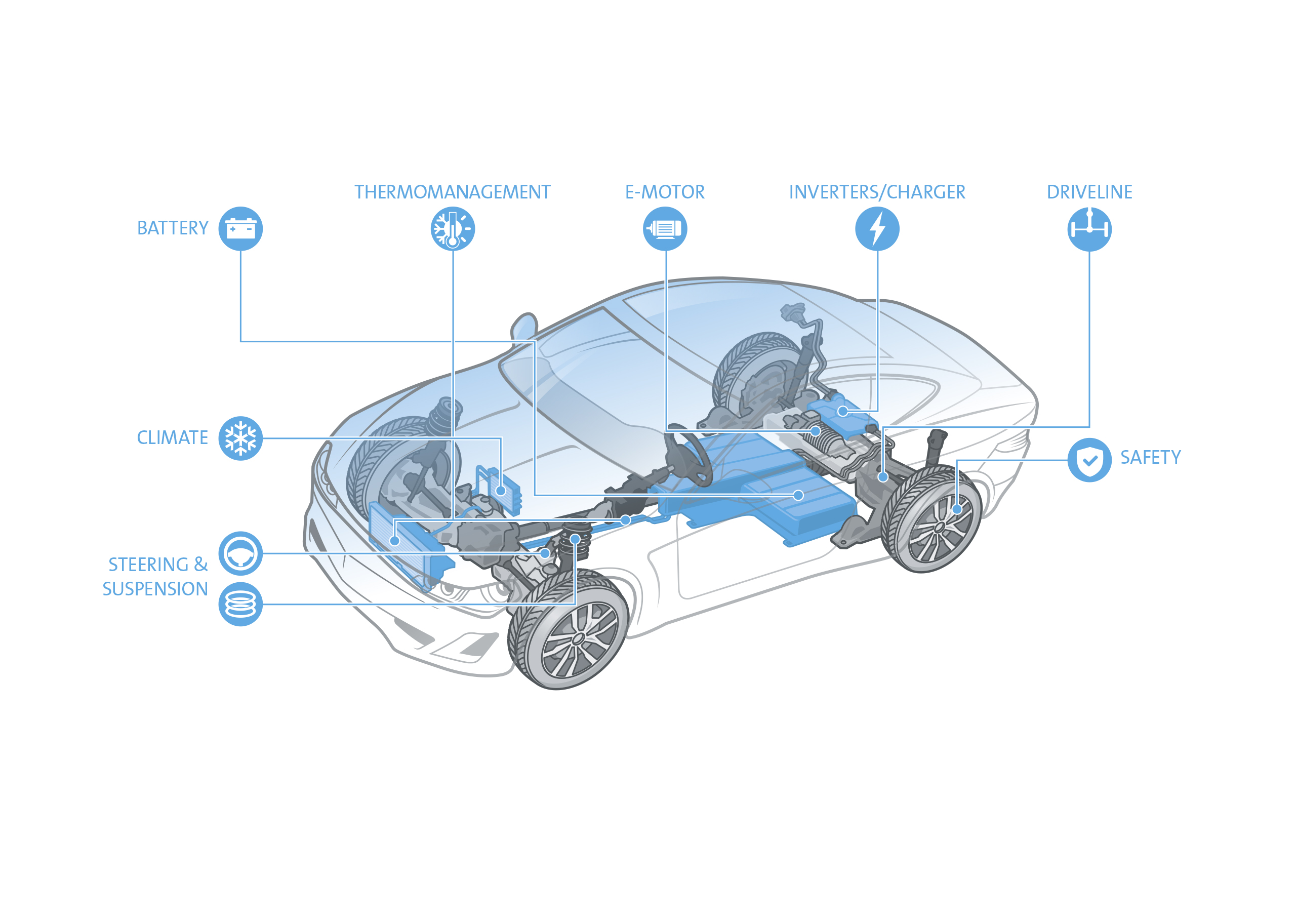

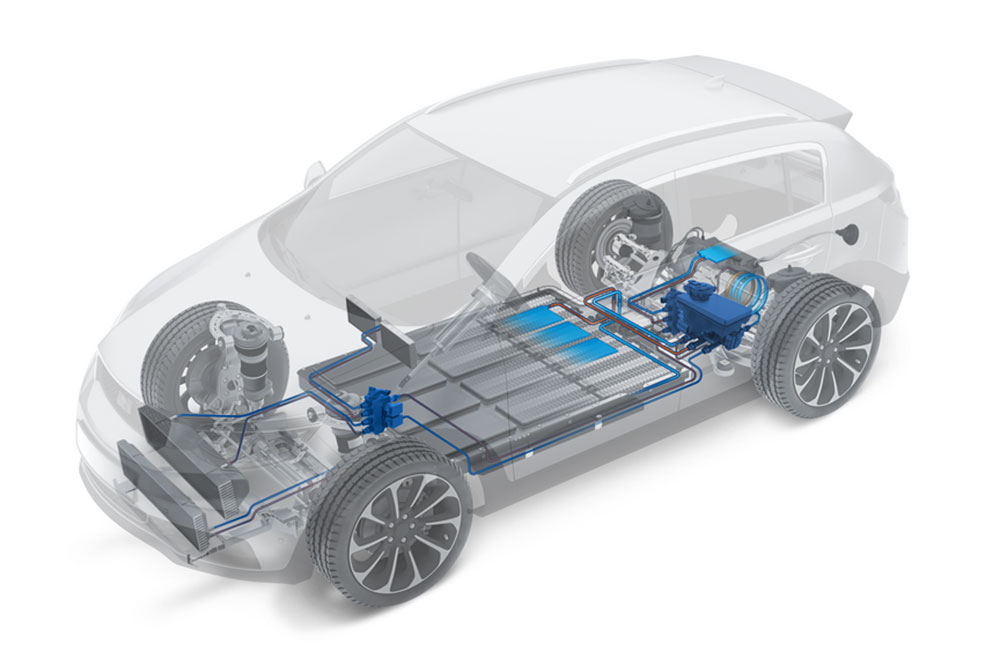

To achieve this, Freudenberg has tapped into its global network of material, engineering and manufacturing experts to design seals that address crucial requirements for optimal E-Mobility powertrains, including thermal management, power efficiency, friction and weight reduction, and compact installation spaces.

“Batteries with a high power density will have a corresponding need for cooling,” said Möhlenkamp. “Having a variety of seal types is indispensable for the transmissions of electrically-driven vehicles. Not to mention, the housings for sophisticated control electronics must be sealed as well.”

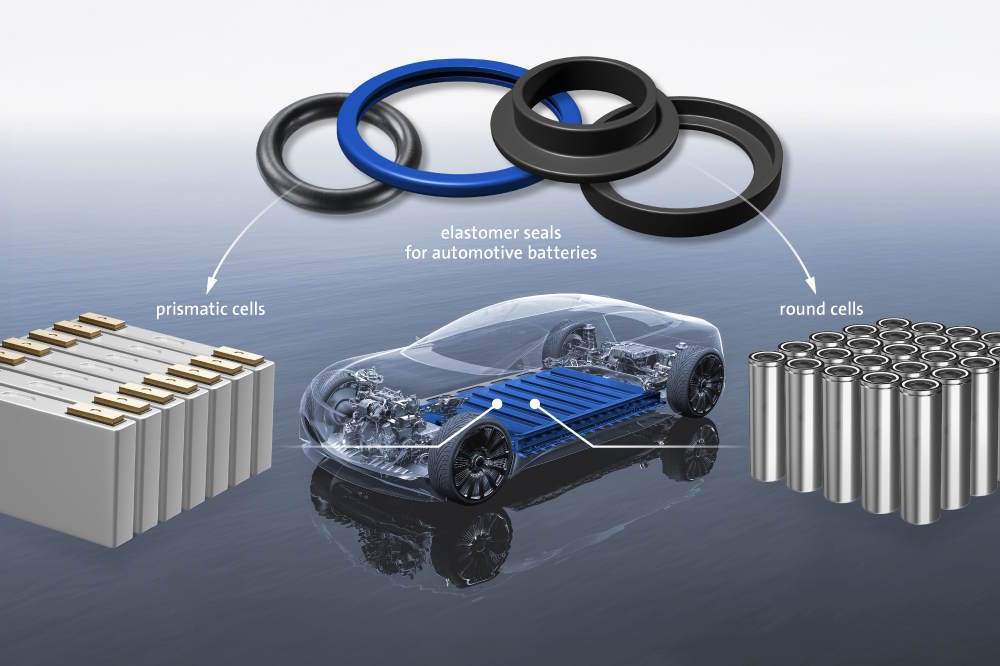

With its expertise in battery safety, Freudenberg has created several sealing solutions in a wide range of materials for lithium-ion batteries that address flammability standards and installation challenges.

Recently, the company also introduced a new housing seal for batteries that optimizes pressure compensation. DIAvent® provides ideal pressure management in large-scale batteries used in electric and hybrid vehicles. DIAvent® is made up of multiple layers of a nonwoven fabric and an umbrella membrane that provide extremely high gas permeation during normal operation. The seal also has a reversible, emergency degassing function in case of a cell malfunction. DIAvent® is water tight and oil resistant, meets multiple protection category requirements for dust, water and particle contamination and can be quickly assembled and installed in the battery.

Freudenberg is also addressing the concern of keeping small volume production of electric vehicles cost-effective by offering a seal for traction battery housings. The patented “Profile to Gasket” concept (P2G) was developed for production volumes of up to 5,000 batteries annually.

Dynamic seals are also needed in electric motors, and Simmerring® Shaft Seals remain indispensable in the transmissions of electrically-powered vehicles. A Simmerring® Shaft Seal featuring a conductive nonwoven element not only saves weight and space but also reduces the risk of a shaft becoming electrically charged and damaging the gearbox.

Freudenberg’s innovative products are also assisting manufacturers with optimization of traditioal internal combustion engines. The company provides solutions such as the Energy Saving Seal (ESS), which can lower friction by up to 40 percent in multi-directional applications, and its Low Friction Simmerring® Shaft Seal (LFS), which reduces friction by as much as 20 percent.

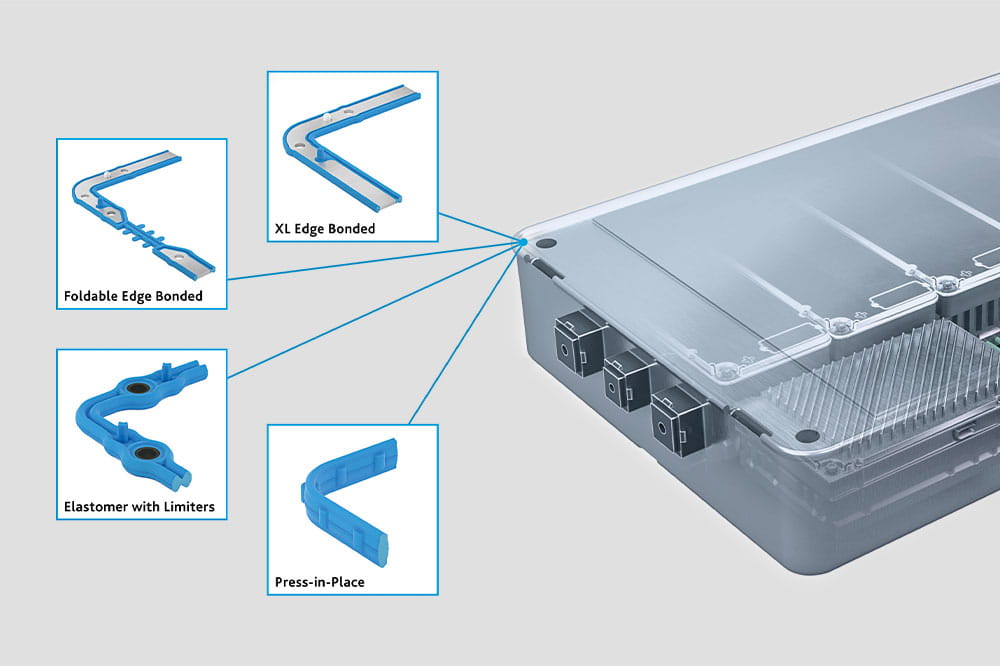

In addition, the benefits of Freudenberg’s 2K Plug & Seal for electric vehicles and hybrids are numerous, offering a reduction in system weight, design customization, complex sealing geometries and chemical bonding between the component’s hard and soft materials, which eliminates potential leakage. The company also offers Encoders, Edge Bonded Seals, Plug and Seal components and Coated Embossed Gaskets for all powertrain technologies.

More information on Freudenberg Sealing Technologies activities in electric mobility can be found here.

Visitors to NAIAS are invited to view all of Freudenberg’s innovative sealing solutions Jan. 16-18, 2018 at its display at the Crowne Plaza Hotel Detroit Riverfront in the Pontchartrain Room.

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.