Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

14.05.2018 | Press release

Freudenberg Addresses Current and Future System Challenges in the Automotive Industry

Plymouth, Mich., May 14, 2018. The vehicle landscape is changing. By 2025 – just seven years from now – experts at Freudenberg Sealing Technologies believe electric vehicles will reach significant production volumes. But even as they do, internal combustion engine (ICE) cars and trucks will maintain an important role in the transportation industry for the foreseeable future.

With dual product development paths guiding its efforts, Freudenberg will showcase a portfolio of sealing innovations this week at the 12th International CTI Symposium USA Automotive Transmissions, HEV and EV Drives in Novi, Mich. The company’s technologies address common system challenges including friction, heat, pressure, installation space and efficiency.

“The automotive industry is undergoing profound transmission and driveline changes,” said Michael Tercheck, Global Sales Director for Freudenberg’s E-Mobility sector. “Vehicle electrification strategies are driving unprecedented technological innovations and we are developing new technologies to support them."

“But at the same time, companies still want to improve the operation of traditional ICE cars, trucks and SUVs,” Tercheck continued. “The E-Mobility research and development strategies our customers are pursuing are being funded by the success of their current vehicles. So it’s crucial that we continue to help our customers address efficiency in both arenas.”

Energy Management for E-Mobility

The automotive industry’s need to effectively and efficiently harness energy, whether generated from batteries, fuel cells, gasoline or other fuels, is the common denominator for Freudenberg’s research and development efforts. The company is successfully pursuing fuel cell developments as well as a growing portfolio of lithium-ion battery components that focus on thermal management, safety and multi-function capacity.

Freudenberg’s Simmerring® Shaft Seal with Electrically Conductive Nonwoven Material, for example, will be on display at CTI. While traditional radial shaft seals can be used in hybrid and pure electric vehicles, the input shaft can become electrically charged and can send damaging charges through the gear box and other components.

Freudenberg’s Simmerring® with electrically conductive nonwoven materials eliminates these risks through a fleece ring glued onto the air side of the seal. Because the carbon fiber-PTFE nonwoven material contacts both the shaft and the housing, the design forms a conductive bridge which grounds the gear box and prevents mechanical system damage. This integrated function saves costs, weight and space. It can also protect against electromagnetic interference (EMI) which helps with radio reception quality.

Other innovations will also be highlighted at the show. The company’s DIAvent® pressure compensation element handles pressure compensation during normal operation and emergency situations via one component consisting of a nonwoven layer and umbrella valve with reversible switching. Its patented „Profile-to-Gasket” (P2G) seal for traction battery housings was designed to accommodate small production volumes of up to 5,000 batteries per year. Batteries with substantial power densities and the resulting cooling requirements create a need for flat seals or the so-called Plug & Seals that Freudenberg Sealing Technologies manufactures as well. Another promising area is lightweight design for electric motors, using plastics that conduct electricity or heat or insulate against them.

ICE Innovations Still Abound

Freudenberg is still pursuing cutting-edge technology for traditional powertrain systems as well. The company’s award winning Low Emission Sealing Solution (LESS) portfolio of engine, transmission and E-Mobility product solutions, for example, have been designed to help the industry universally achieve more eco-friendly cars and trucks. LESS products include a variety of low friction seals, gaskets, encoders, accumulators, sealing modules and lightweight housings.

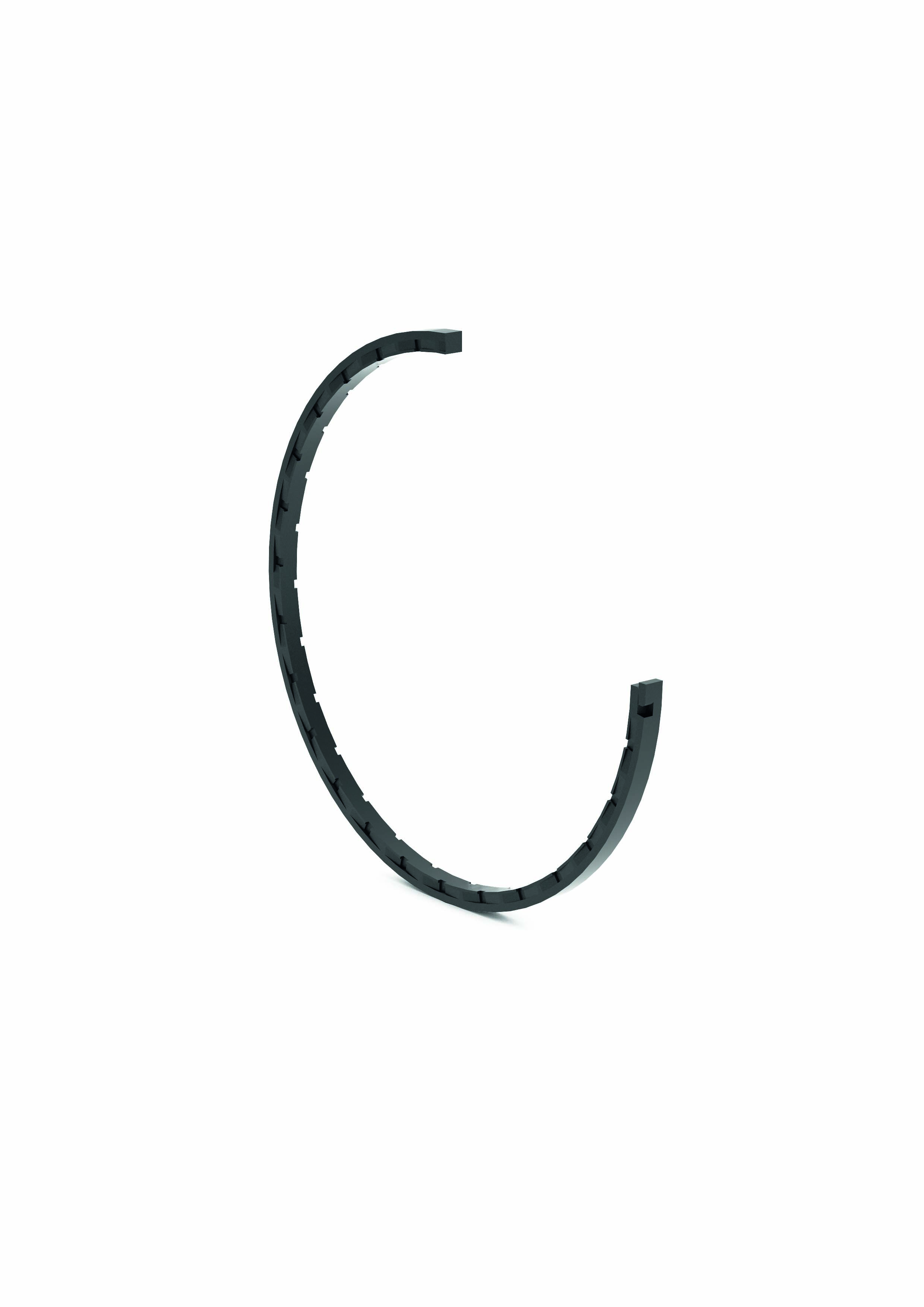

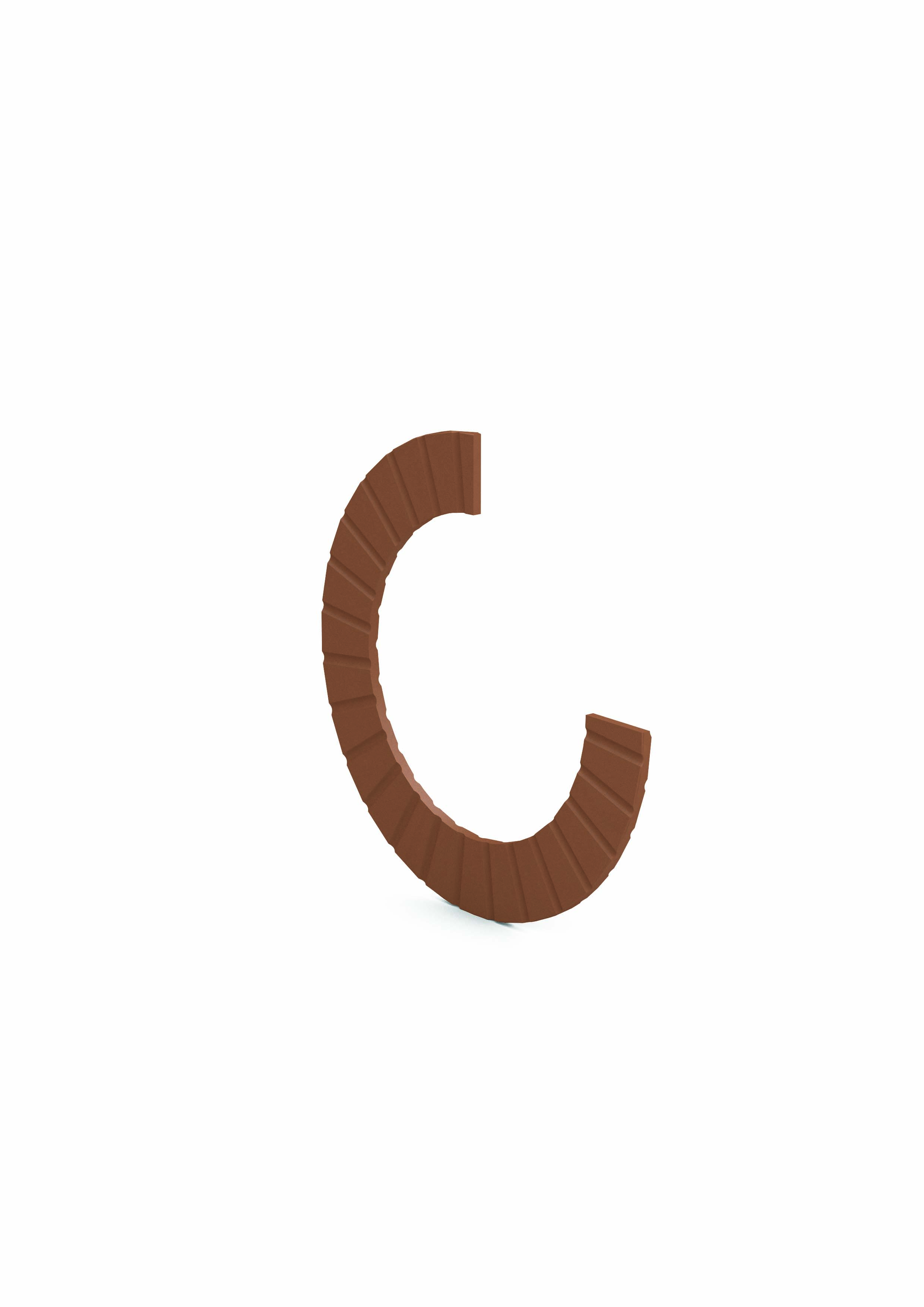

Founded on its flagship gas-lubricated mechanical face seal Levitex® -- which cuts friction by 90 percent and lowers CO2 emissions by up to 1 g of CO2 per kilometer during driving – the LESS portfolio has been recently expanded to include the Levitas low torque seal ring and the Levitorq thrust washer. These sealing options both rely upon hydrodynamic oil film technology to reduce transmission and driveline friction. Levitas seal rings reduce friction and wear to an absolute minimum resulting in significant reductions of CO2 emissions. Levitorq thrust washers enable engineers to replace heavy, torque robbing, metal thrust washers with washers made of thermoplastic or thermoset alternatives, These innovative products help reduce weight, decrease friction, and improve thickness/flatness control. More information on Freudenberg’s LESS portfolio is available at less.fst.com.

Press Release Downloads

Freudenberg Addresses Current and Future System Challenges in the Automotive Industry

Last update: 14.05.2018

English | DOCX | 482 KB

DownloadDownload Images

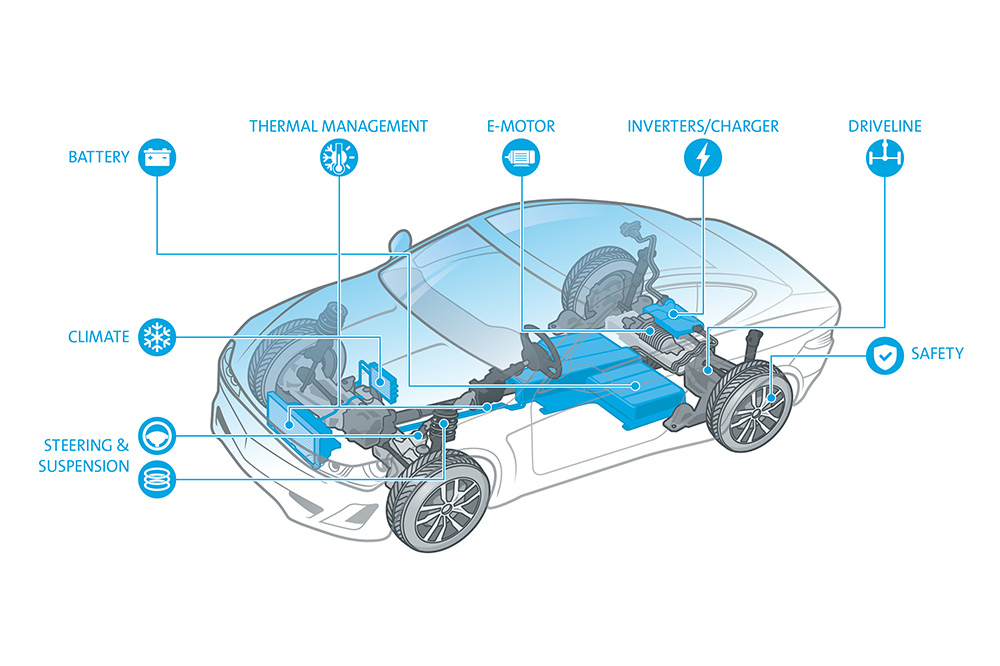

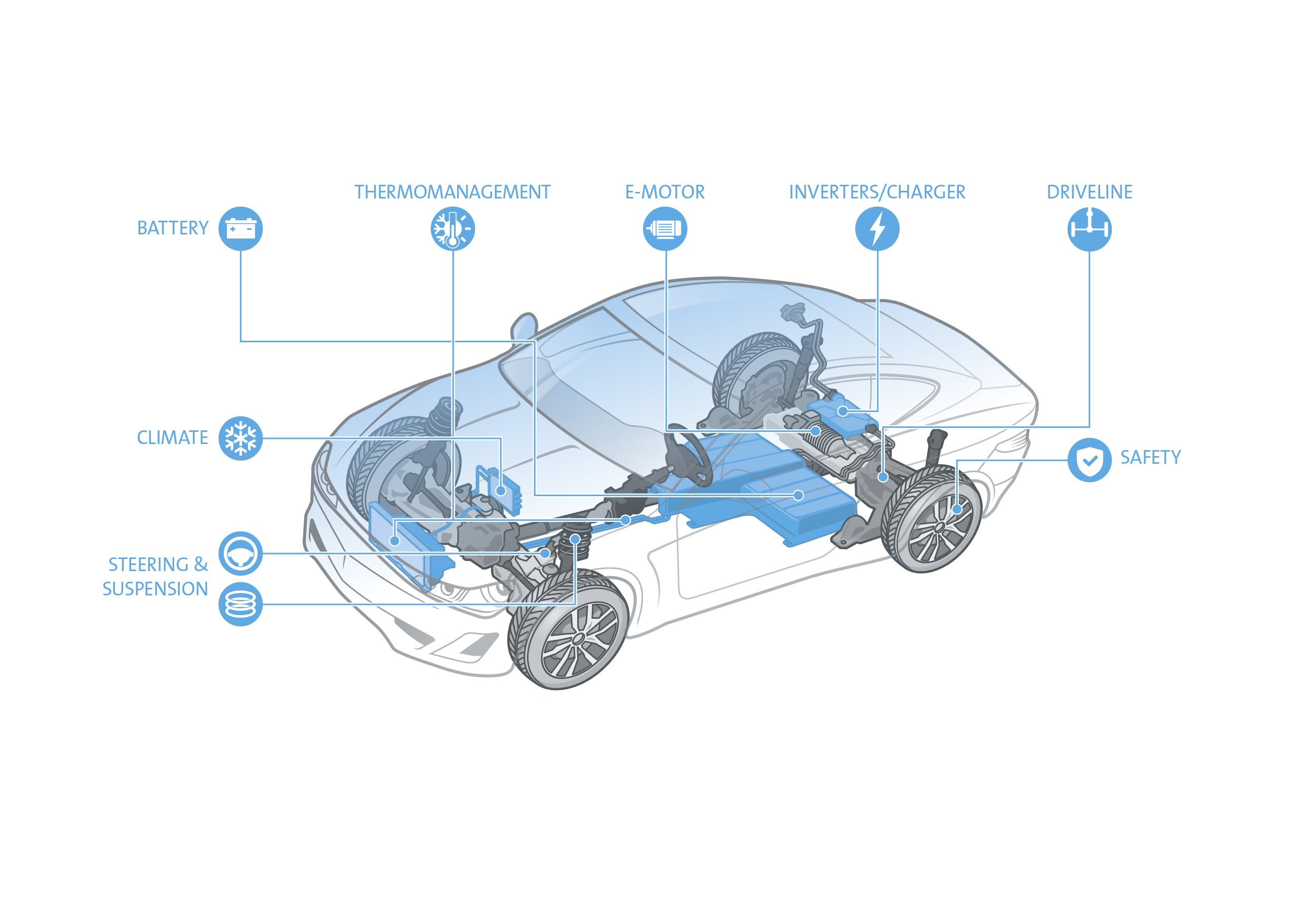

FST e-mobility battery electric vehicle

JPG | 921 KB

Download

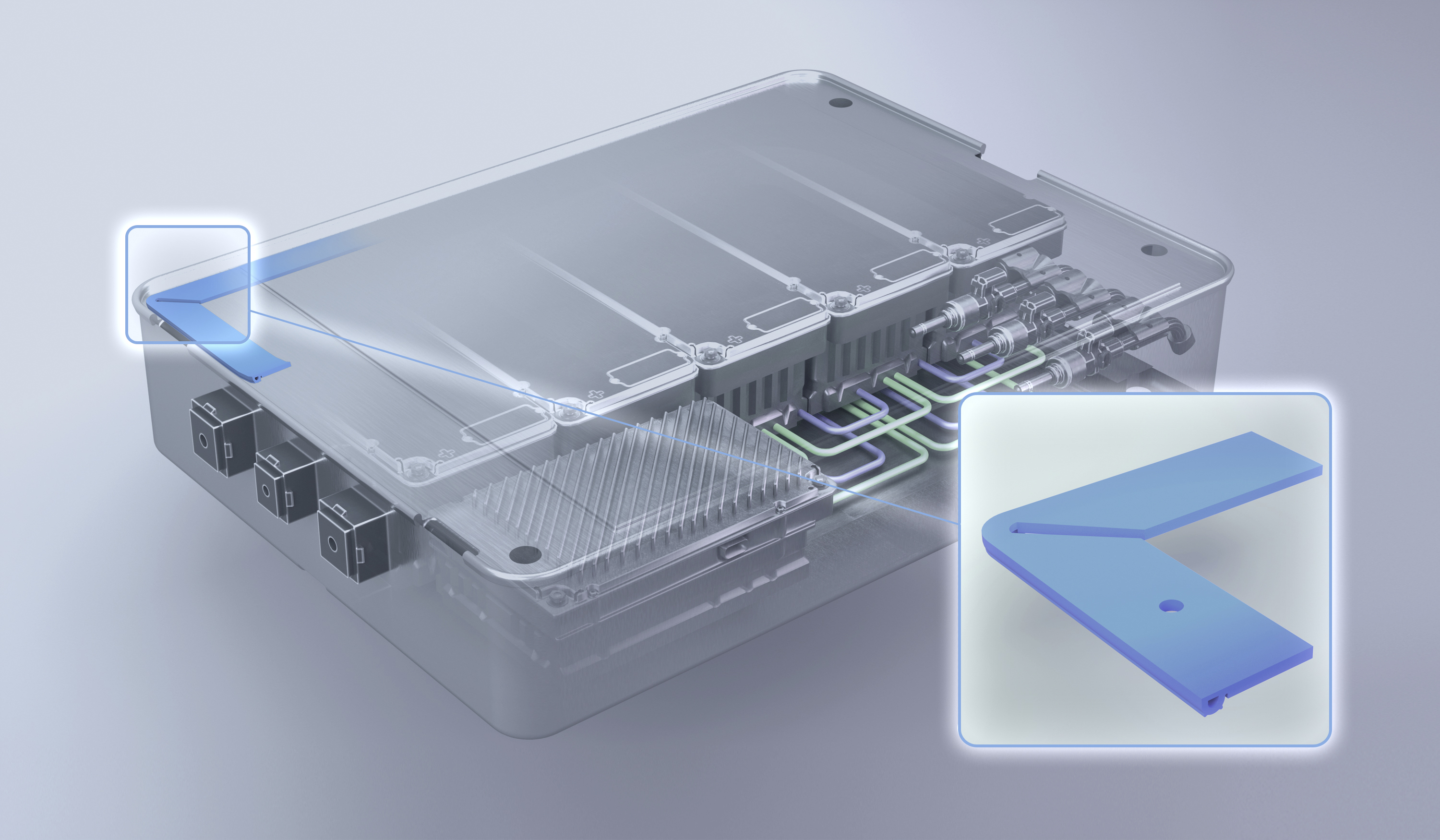

FST PP P2G

DANIELFORTMANN·COM | JPG | 1.89 MB

Download

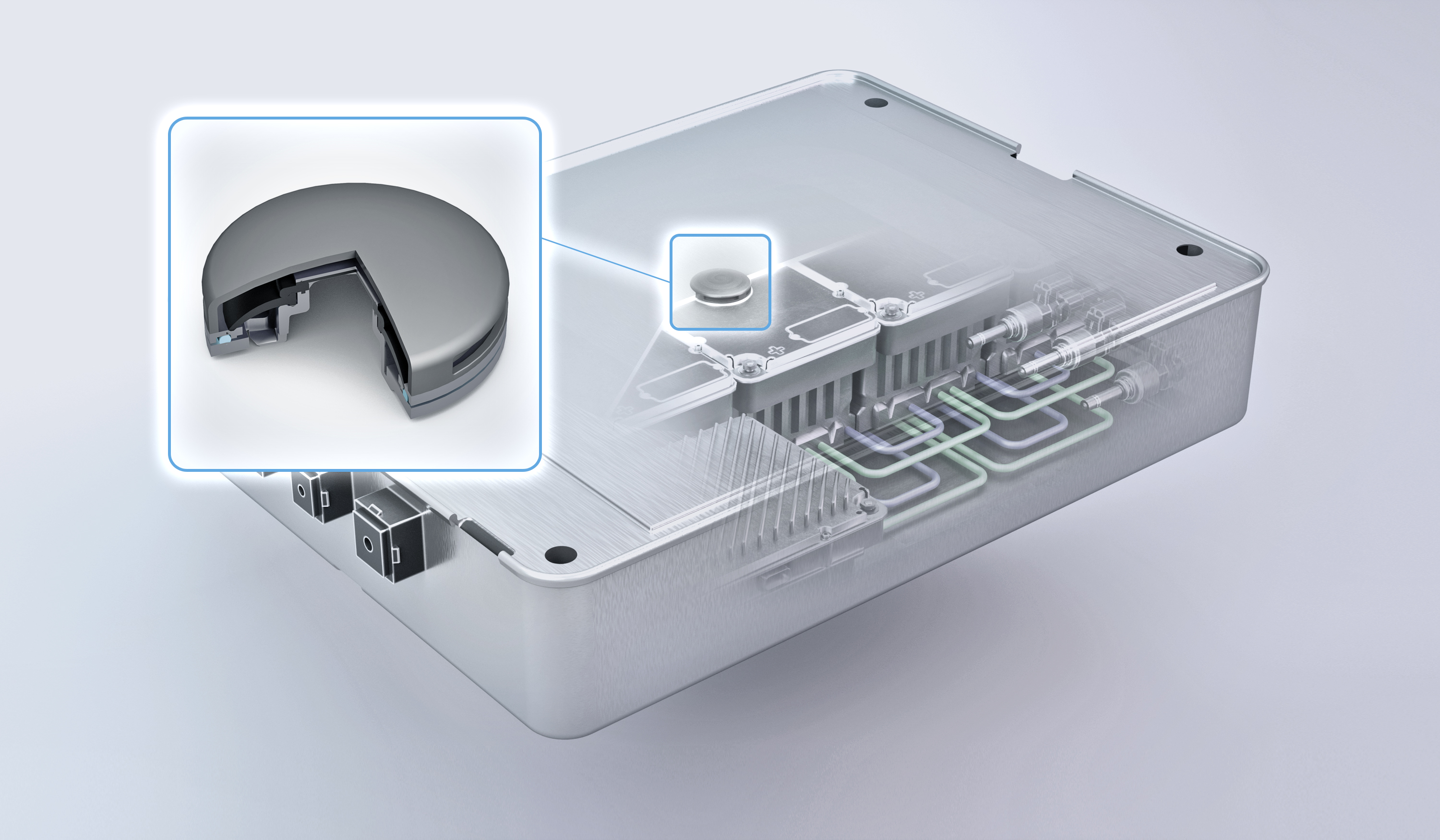

FST DIAvent

DANIELFORTMANN·COM | JPG | 1.64 MB

Download

FST Levitas standing profile

JPG | 2.04 MB

Download

FST Levitorq standing profile

JPG | 2.03 MB

Download

FST Simmerring nonwoven

JPG | 1.8 MB

DownloadNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.