Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

30.09.2025 | News

Reliable Seals For Busbar Pins In Low-Voltage Applications

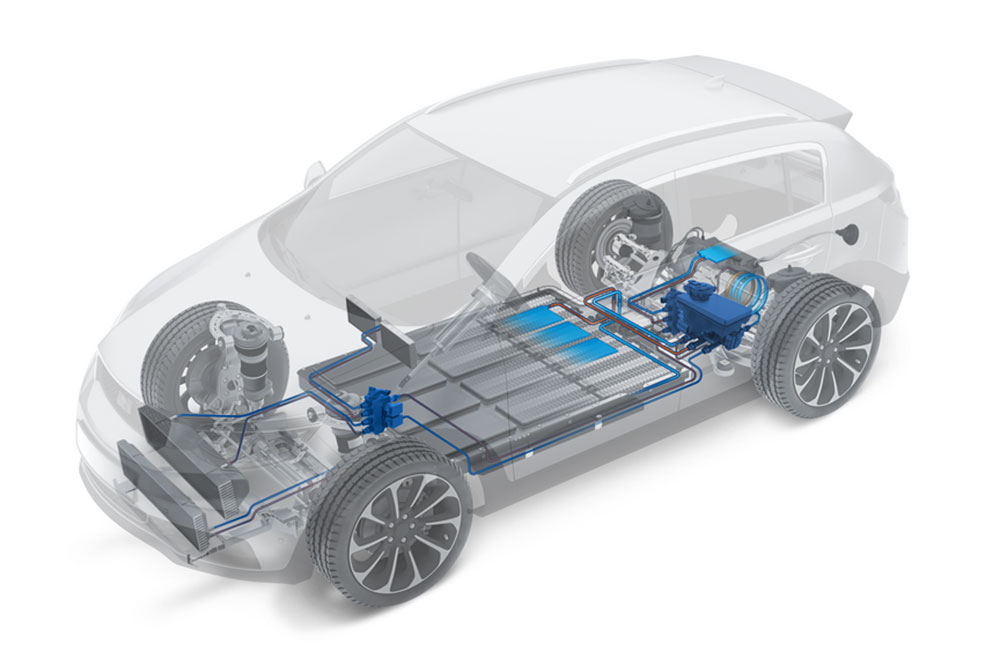

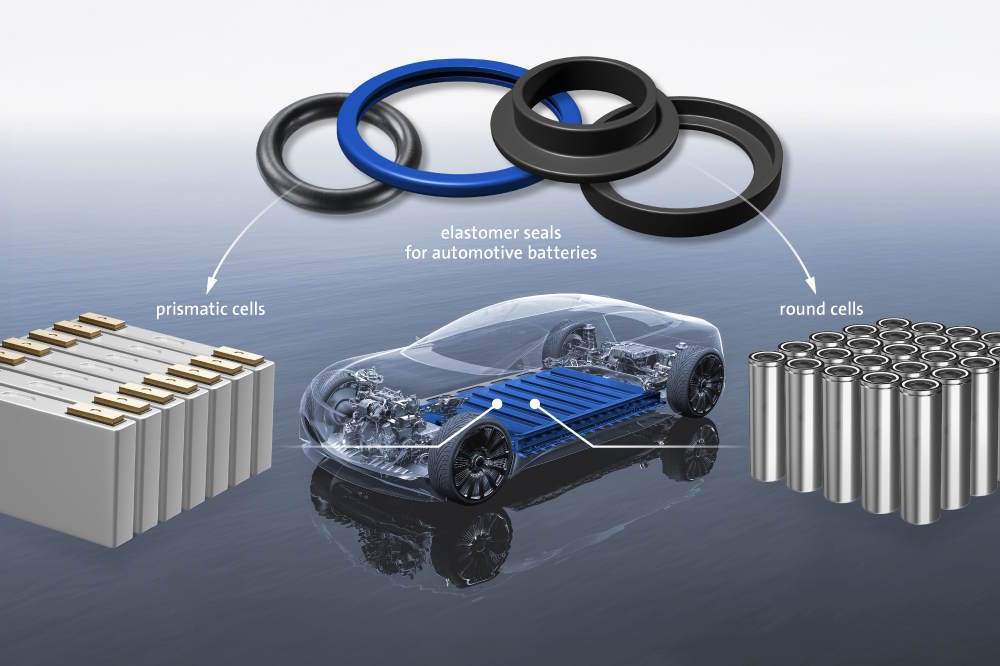

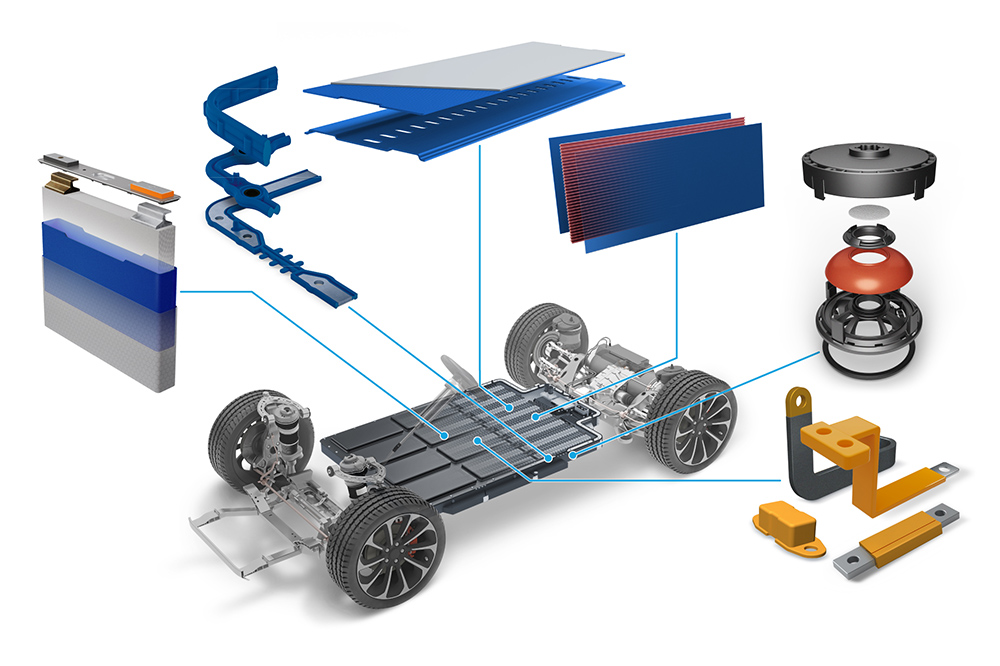

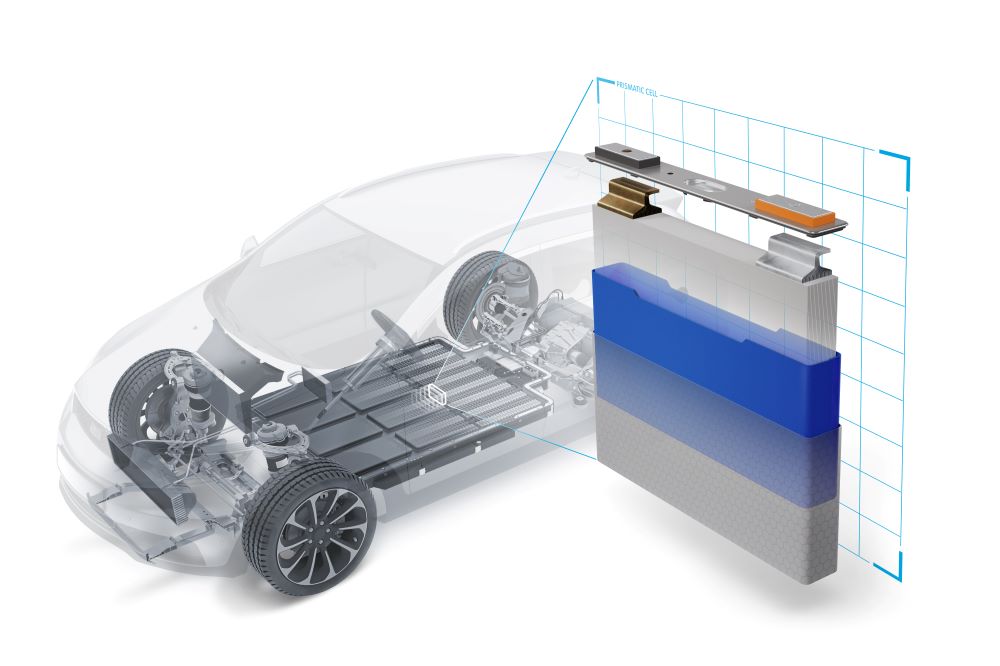

As electrification continues to advance, developers and system suppliers are increasingly focusing on low-voltage applications. Unlike in the high-voltage sector, these are defined by compact components, tight installation spaces and miniature parts. This places especially high demands on the sealing technology.

Seals for busbar pins and electrical plug connections in the low-voltage range

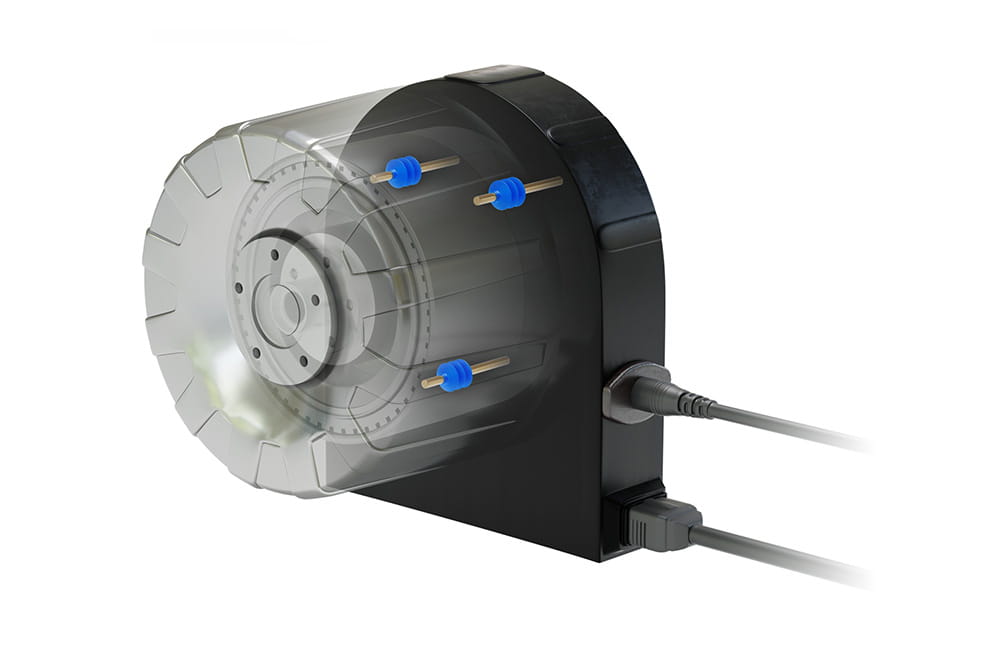

Freudenberg Sealing Technologies has developed new seals for plug connections, electric pumps and compact air conditioning compressors specifically for these applications. The goal is to ensure reliable, media-resistant sealing even with very small dimensions.

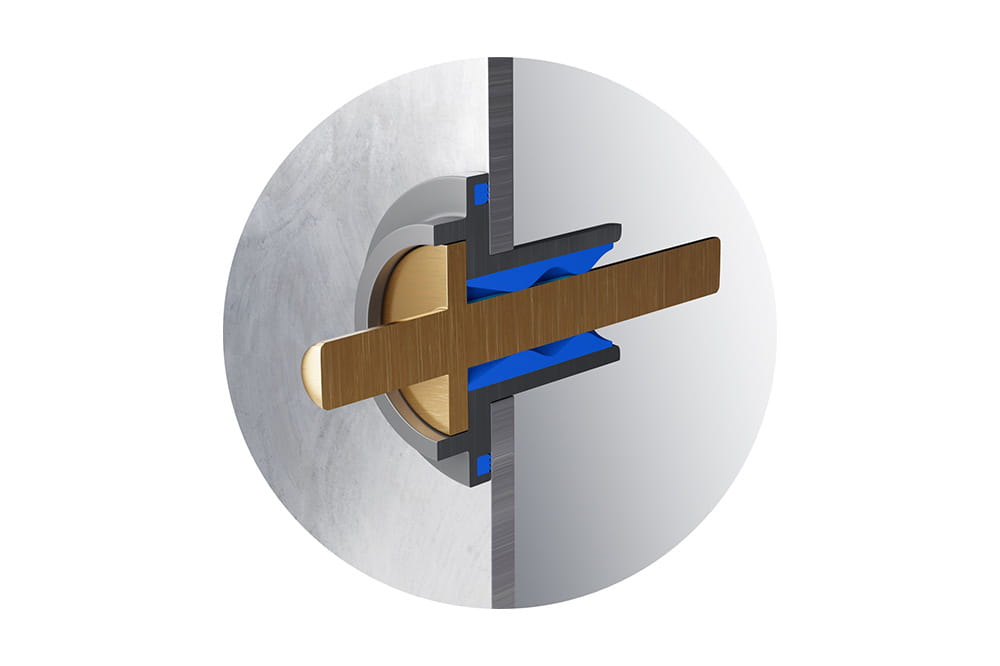

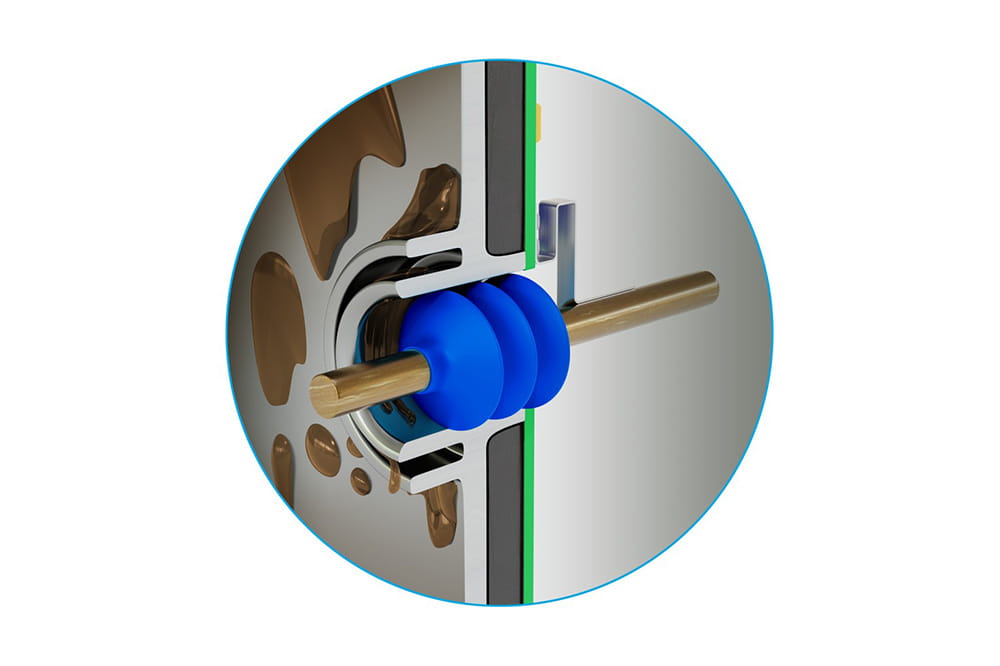

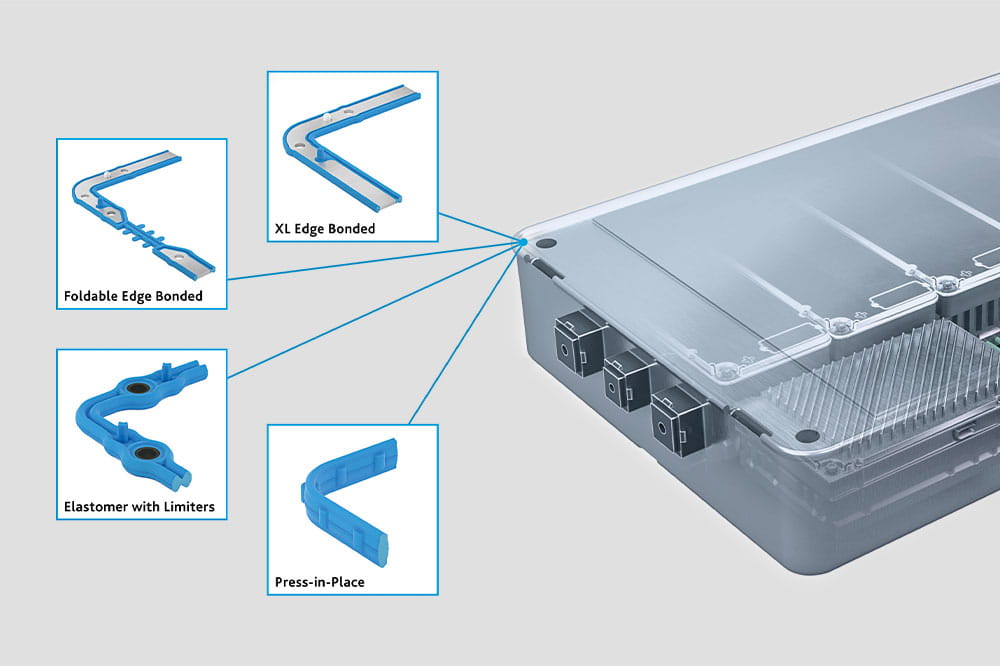

A special focus lies on multi-pin connectors and other small plug connections where numerous pins are housed in tight spaces. Sealing these kinds of miniature components presents unique challenges, particularly with respect to impermeability, protection classes (e.g. IP ratings), material compatibility and thermal stress. Freudenberg Sealing Technologies offers a reliable solution in the form of new sealing concepts – such as the application of an elastomer layer via chemical adhesion, special elastomer coatings or the use of plastic-elastomer composite seals. These approaches make it possible to reliably seal even the smallest geometries, compensate for manufacturing tolerances, integrate multiple sealing functions and simplify the installation. More details on the sealing concepts: Busbar Sealing

Many customers approach us with the challenge of reliably sealing their small busbar pins

Christian Jaschke, Product Manager Incubator Busbar

“Many customers approach us with the challenge of reliably sealing their small busbar pins,” explains Christian Jaschke, Product Manager Incubator Busbar at Freudenberg Sealing Technologies. “Our task is to develop the right technology for them to ensure a high level of functional reliability even in low-voltage applications.”

The added benefit: further integrable functions

Thanks to precise material selection and intelligent seal design, additional features such as tolerance compensation, easier assembly and multiple sealing levels can also be integrated into a single module. The seals are relevant not just for automotive components such as coolant pumps and air-conditioning compressors, but also for applications in general industry.

The low-voltage sealing concepts are the result of continuous technical development with a clear focus on current and future market requirements. Once again, this shows how technological innovation and market insights go hand in hand at Freudenberg Sealing Technologies.

More news on the subject E-Mobility

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.