Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

31.03.2025 | News

Freudenberg Sealing Technologies Propels Humanoid and Industrial Robots

High-performance seals are used in robotics. Freudenberg Sealing Technologie offers excellent material combinations for these products.

Weinheim — Freudenberg Sealing Technologies is increasingly taking its long-standing sealing expertise in industrial robotics and applying it to humanoid robots. A specialist in high-performance seals, the company combines an in-depth knowledge of materials with state-of-the-art production technologies. In a short time, it can develop precise solutions for a wide range of applications. This manufacturing expertise is especially in demand for industrial automation: In these cases, seals must withstand extreme stresses – whether from aggressive chemicals, high temperatures, or powerful mechanical forces. For example, special elastomers and high-performance plastics in robotic arms make sure that their movements are precise and reliable – even under challenging conditions and over long periods of time.

Sealing competency – paving the way for humanoid robots

The requirements for humanoid robots are even more demanding. Their joints and actuators require highly compact, flexible and resistant seals to produce natural agility and block external influences. At Freudenberg Sealing Technologies, materials are already available to allow ball, pivot and rotary joints to operate in very small installation spaces. The company has also developed a range of high-performance seals for the different drive systems used in humanoid assistants. Their electric motors, hydraulics and sophisticated pneumatics cannot function without special seals for power transmission and motion control.

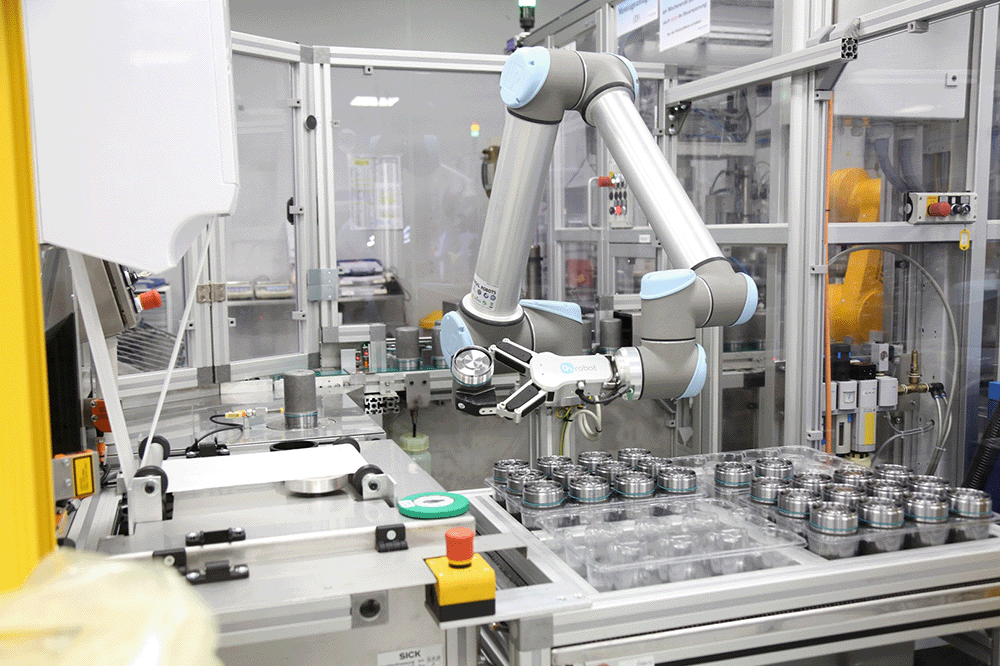

Radial shaft seals – maintaining cobots’ high-performance

Radial shaft seals are key components in robots because they are the interface between rotating and fixed parts. Their job is to simultaneously keep lubricants inside and dirt particles outside the equipment. Especially in the field of collaborating robots, the machines are subjected to extreme mechanical forces: Rapid acceleration, sudden braking and constant rotation exert stress on components. Friction plays a crucial role here. With the help of specific materials and optimized geometries, Freudenberg Sealing Technologies is reducing the effects of friction to a minimum – even at high rotational speeds and low cycle times. Seals in this category also operate with minimal energy losses and low wear. This in turn extends maintenance intervals considerably, which helps to reduce operating costs.

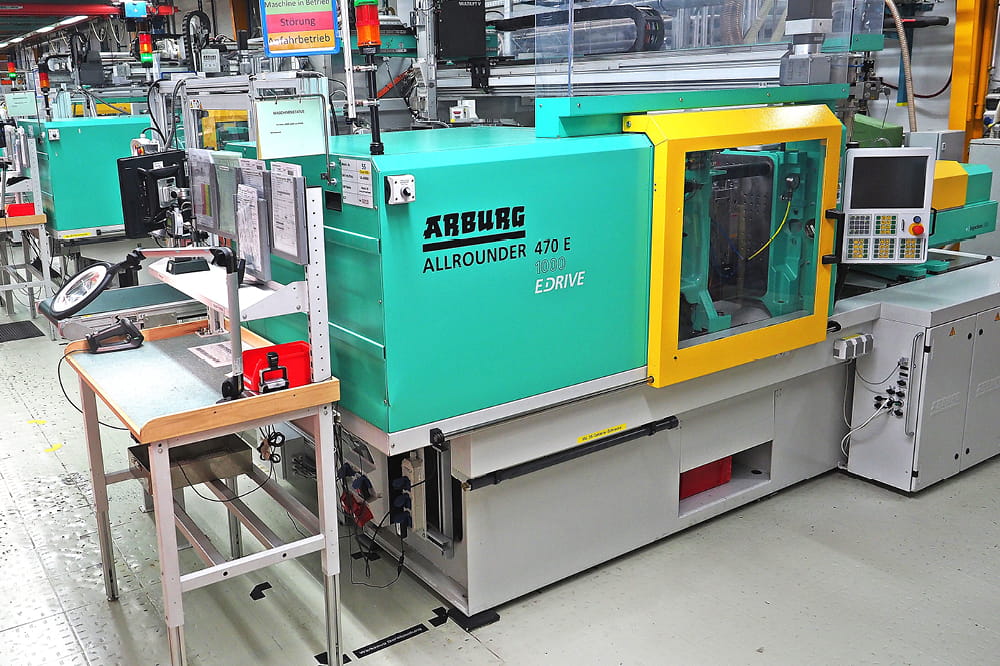

Seals for industrial robots – achieving high robustness and a long operating life

Industrial robots often have to operate under harsh environmental conditions. including high temperatures, dust, water or chemicals. One main challenge is sealing gearboxes efficiently to keep lubricants from escaping and foreign particles out. Freudenberg Sealing Technologies provides the robotics sector with high-performance materials that not only resist mechanical wear but aggressive media as well. These sealing and shock-absorbing solutions help to keep robotics systems running in demanding production environments, including those found in the food industry or in cleanrooms.

Using the test environment – Freudenberg Sealing Technologies testing operations

As part of a vertically integrated production environment, Freudenberg Sealing Technologies has its own testing capabilities. In all, more than 300 test stands are available to the company’s customers on demand, providing comprehensive test and validation capacity for made-to-order tests. The work is done at the world’s largest testing operation for dynamic seals in Weinheim, Germany, and at the company’s test facility in Ashland, New Hampshire (USA). Realistic scenarios are explored to optimize the interplay of gearboxes, lubricants and seals. With comprehensive tests, Freudenberg Sealing Technologies can ensure that its products meet industry’s high standards. Well-known robotics manufacturers are already taking advantage of this expertise to test components under real-world conditions and to improve their product quality long-term.

Looking at a growth market – taking robotics to the next level

With its advanced sealing solutions, Freudenberg Sealing Technologies is making a key contribution to the development of robotics. Hunter Cheng, Global Segment Manager Robotics at Freudenberg-NOK Sealing Technologies, puts it this way: “Ultimately, it is the interplay of gearboxes, lubricants and seals that determine how precise and reliable robots operate. Whether humanoid or industrial robots – our high-performance seals provide maximum performance, a long operating life, and minimal maintenance – an essential condition for the automation of the future.”

Modular plastic seals – sustainable flexibility outdoors

Service robots such as mowing or cleaning robots are benefiting from Freudenberg Sealing Technologies’ sealing solutions. These applications rely on modular plastic seals that are optimized for outdoor use. They keep moisture, dirt and mulch from getting inside the robots’ motors and wheel bearings. The seals stand out for their sustainability, in addition to their robust construction. They are made from recyclable plastics and can be adapted into various configurations. It is possible to produce them flexibly and efficiently while meeting the needs of a growing market for household and garden robots.

More news on the subject Robotics

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.