Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

20.12.2023 | News

Hydrogen: Setting Benchmarks Again

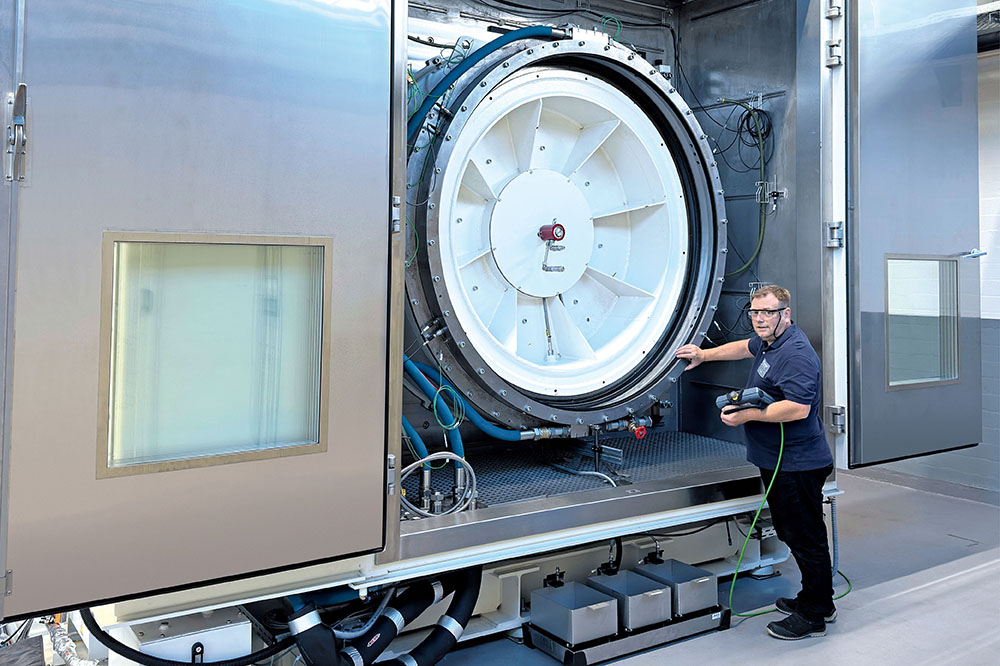

Weinheim, December, 20, 2023. Innovating Together: Thanks to the interaction of several lead centers and departments, it has been possible to develop a market-ready extruded profile seal for use in the production of hydrogen. It was developed in short order and is now being used in alkaline electrolysis processes. The participants in a second project are now planning new, fundamental developments for the next generation of electrolyzers.

“Hydrogen – A Resource for the Decarbonized Future.” That is a headline in a guide to hydrogen that Freudenberg Sealing Technologies (FST) authored for the chemical industry. The white paper describes the development capabilities of Freudenberg Sealing Technologies (FST) relating to ¬hydrogen applications.

In a project for a well-known European maker of alkaline electrolyzers, FST has shown that these descriptions are not merely theoretical – they represent real-life practice. Several specialist departments have developed a new sealing solution together with the customer for a well-known European manufacturer of alkaline electrolyzers.

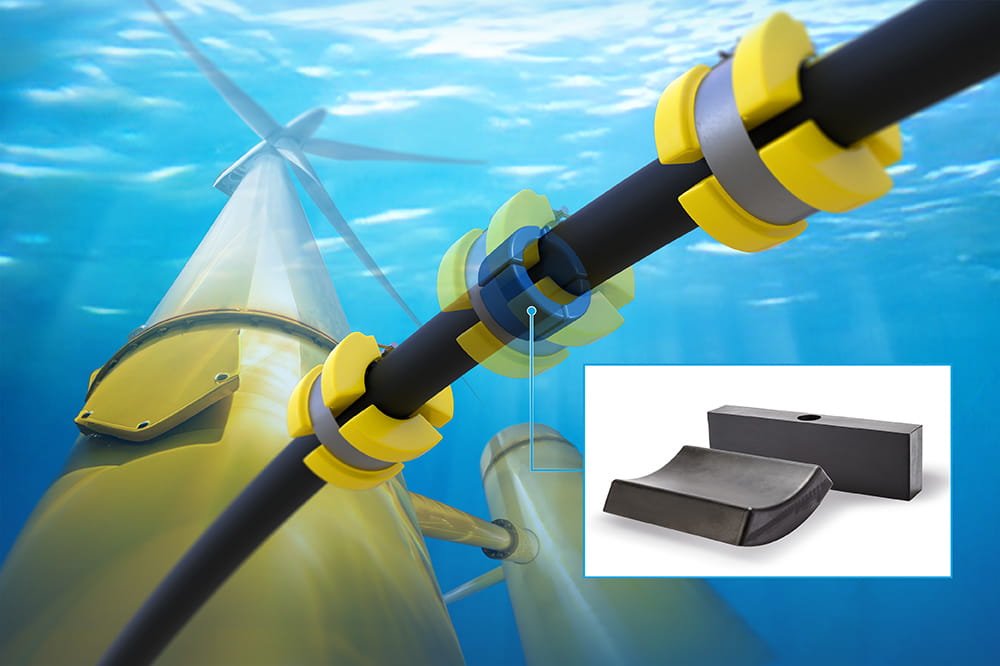

The timeframe was tight, and, as the electrolysis stacks already existed, the degree of freedom in designing the seal was limited. The installation space was already set. The design of the profile seal was successfully optimized through extensive analyses, calculations and tests. With the unaided eye, one can see the change from the original flat design of the competitive product that had been used. It now has the spherical geometry of a profile seal. The functionally relevant overlap to the contact partners was thus increased while at the same time reducing the critical groove filling of the initial design.

The second focus was on development of a permanent and sustainable material to replace asbestos, a known health hazard. The challenge: In alkaline electrolyzers, the sealing material must withstand a highly concentrated potassium hydroxide solution, as well as oxygen, “which drive deterioration.” It must also have a long lifespan and withstand enormous pressure and increased temperatures.

The experts of FST immediately analyzed FST’s portfolio of materials. In the short time available, an EPDM material emerged as the best solution. In specially executed storage trials, it exhibited better resistance to potassium hydroxide and oxygen than the material of a rival company.

500 Kilometres per Year

Since a single profile measures about 5 metres in length for each electrolysis cell, the seals needed to be manufactured via endless extrusion. The project team assumes an annual production volume of 500 kilometers. Currently (Status at the end of September), the seals were at the customer for evaluation and the first series quantities were ordered.

But there is more. Shortly after the first contact, it turned out that the customer was interested in a more in-depth collaboration with FST with the next generation of electrolyzers in mind. The team working on the first project is currently defining the content and framework conditions for this second, much more far-reaching development project. FST can then also incorporate its existing expertise into the design of the sealing environment - to improve the overall system.

Based on projections, the demand for hydrogen is expected to grow explosively in the chemical industry and in sustainable energy carriers, storage systems and fuels for fuel cells, serving as a key resource for a decarbonized future. In this light, these kinds of basic development projects with customers are tremendously important for FST’s future. The project team agrees that “Innovating Together” offers the opportunity to gain experience, learn and develop while collaborating with customers. The projects become a good reference and demonstrate expertise in development. Never standing still, always making progress, and setting standards in new fields of application – in the end, that is a component of FST’s DNA.

More news on the subject Renewable Energies

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.