Seals for Engines and Auxiliary Power Units (APU)

Seals for Engines, Auxiliary Power Units (APU), Nacelles and Pylons

Engine seals from Freudenberg Sealing Technologies: The driving force of modern aircraft

Powerful engines and auxiliary power units (APUs) are key components of global aviation. While the main engines generate the propulsion required to get and keep aircraft in the air, auxiliary power units ensure that the lights in the cabin do not go out even when the aircraft is on the ground. They can also provide emergency power to critical flight controls in the event of an emergency.

Innovative sealing solutions and materials are essential for the safety, efficiency and sustainability of aircraft components. This is because they have to reliably withstand the high requirements over a long service life.

Freudenberg Sealing Technologies develops highly specialized seals and materials for these demanding systems. They protect engines and associated systems such as pylons, nacelles and thrust reversers from extreme temperatures, high speeds and aggressive operating media. They help to reduce fuel consumption and optimize operating costs.

The Challenges

Engines - the power plants of the air

As the most powerful systems on an aircraft, engines operate under extreme conditions and are crucial for efficiency and performance.

What challenges do seals in aircraft engines need to overcome?

- Extreme temperatures: Temperatures above 1,000 °C in combustion chambers and turbines.

- High speeds: Shafts and bearings require precise, heavy-duty seals.

- Aggressive media: Seals must withstand aviation fuels such as AVGas, Jet-A, SAF fuels, oils and hydraulic fluids.

-

High efficiency requirements: Seals must minimize friction losses in order to ensure the efficiency and thrust of the engines in the long term.

Auxiliary power units (APU) - Power supply on the Ground and in the Air

Auxiliary power units (APUs) are indispensable for the operation of modern aircraft. They are usually located at the rear of an aircraft and supply energy for electrical and pneumatic systems, especially when the main engine is switched off - for example during the ground phase or when preparing for take-off. APUs work under constant loads and must be efficient, durable and reliable.

What are the challenges in sealing of APUs?

- Continuous load: APUs must provide energy over longer periods of time.

- Moderate temperatures: Operating temperatures are lower than for main engines, but require robust materials.

- Vibrations: Seals must be flexible in order to withstand vibrations and movements.

- Efficiency: Low weight and reliable functionality are crucial.

Freudenberg Sealing Technologies offers specially developed seals and materials that are tailored to the challenges of APUs and ensure long-term functionality with minimal maintenance.

Nacelle and Pylon Sealing: Ensuring Safety and Performance in Extreme Conditions

Sealing in nacelles and pylons is critical for ensuring the safety and efficiency of aircraft engines. These components face unique challenges that require specialized solutions.

What are the challenges?

- Extreme Temperatures: Nacelles and pylons must withstand high temperatures, often exceeding 1,000°C, which can compromise the integrity of standard seals.

- Vibration and Mechanical Loads: The constant vibration and mechanical stresses in these areas demand seals that can maintain their performance without degradation.

- Aggressive Operating Media: Exposure to kerosene, oils, and hydraulic fluids necessitates seals that are highly resistant to chemical attacks.

Freudenberg Sealing Technologies (FST) addresses these challenges by producing fire-proof seals that comply with AC20-135 and ISO2685 standards, ensuring no burn-through of materials for 15 minutes at 2000°F. This advanced sealing technology provides reliable protection and enhances the overall safety and performance of aircraft engines.

Aerospace Sealing Product Range

Elevating Aviation Standards

Our O-rings excel in aircraft functions, delivering Six Sigma quality and exceptional resistance to temperature and chemicals. Available in AS568, BS1806, and metric sizes, our exclusive elastomer formulations promise versatility across diverse applications, meeting industry demands with unparalleled performance.

Versatile Performance

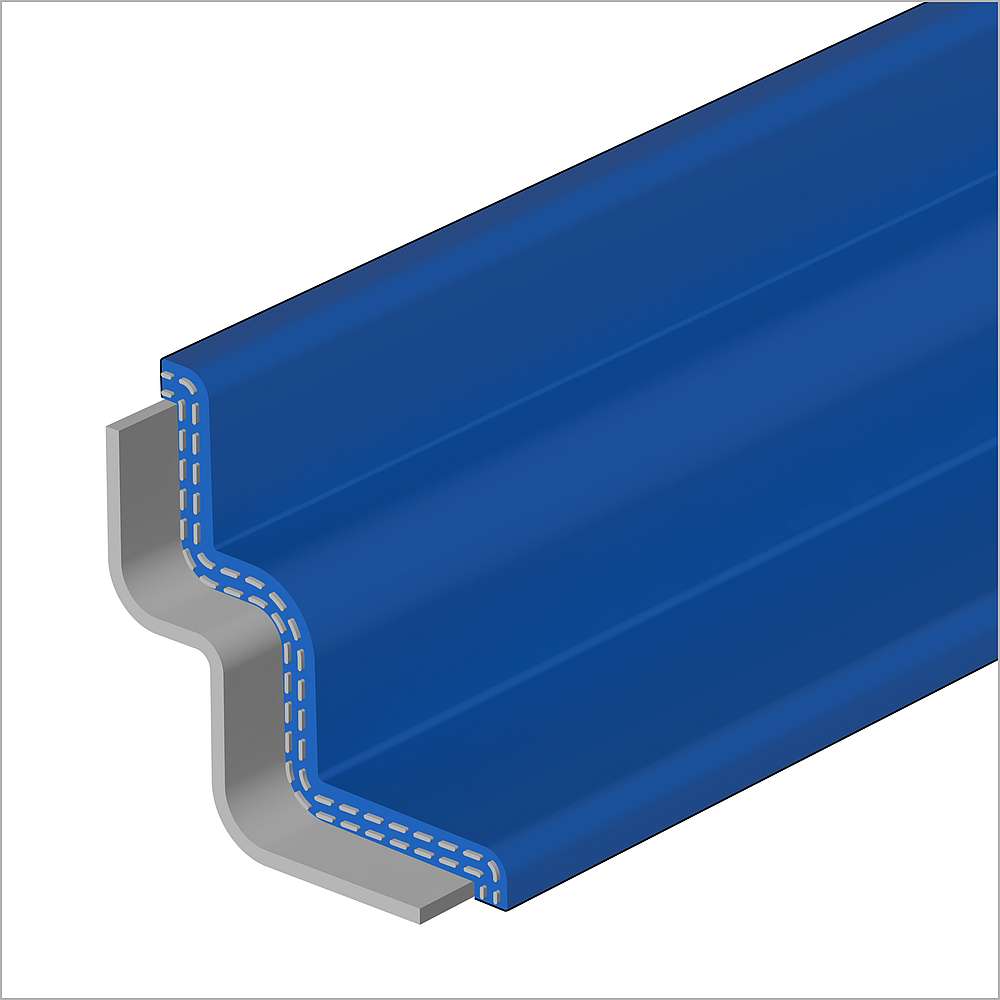

Our plate seals provide cost-effective versatility with specialized carrier and sealing materials, guaranteeing resilience in engine, fuel, and hydraulic systems against extreme temperatures and diverse media. Innovative designs streamline assembly, reduce costs, and offer an alternative sealing approach, optimizing efficiency.

Resilience in Extreme Conditions

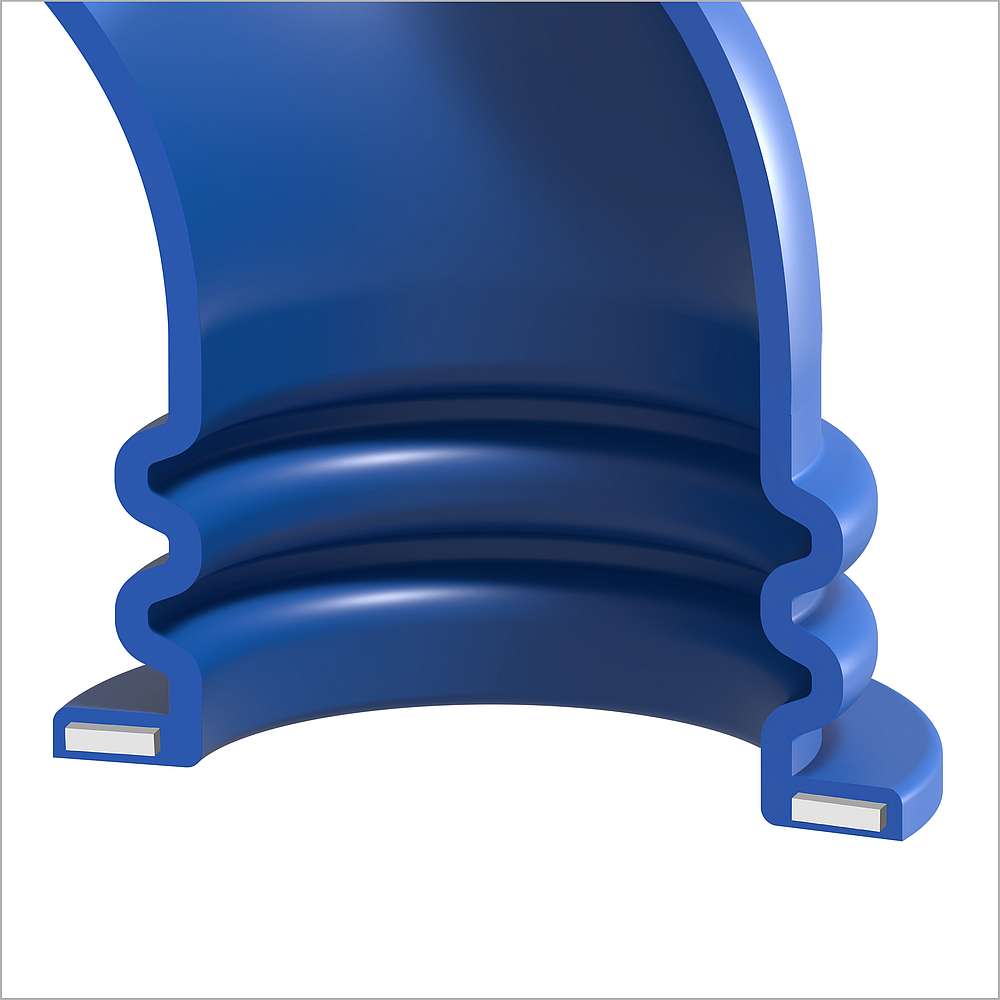

Our fire-resistant seals, crafted from proprietary elastomers and fabrics, endure 2,000°F / 1,100°C fires for 15 minutes according to AC 20-135 / ISO 2685 standards. With or without fabric reinforcement, our expertise ensures customers achieve test success on the first attempt, bolstering their trust in our capabilities amid extreme conditions.

Flexible Fluid Transfer Solutions

Our elastomeric ducts, offering flexibility and lightweight construction, facilitate smooth liquid or gas transfer between rigid interfaces. Engineered for extensive movements and tolerances, they exhibit fatigue resistance. Utilizing proprietary materials, these ducts guarantee prolonged durability in extreme conditions and aggressive environments, with the option for added fire protection.

Strengthening Sealing Reliability

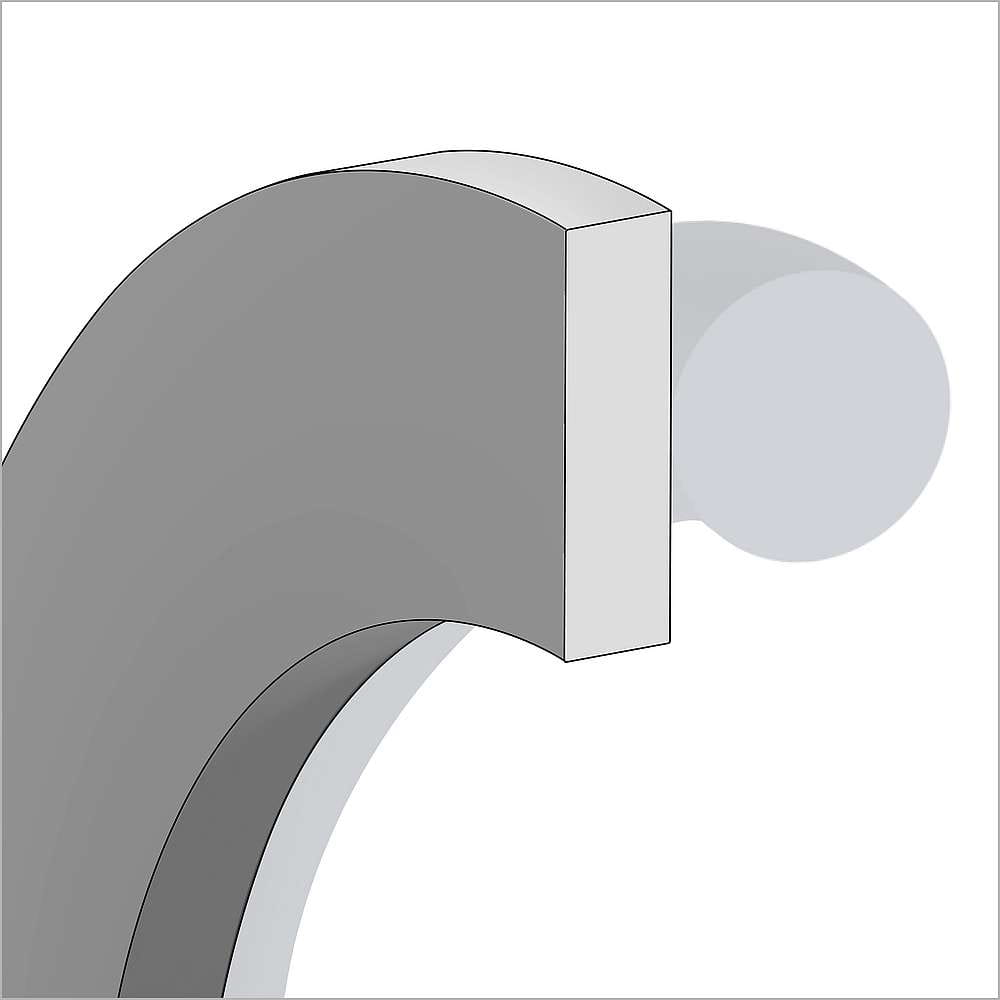

Our PTFE back-up rings elevate the sealing performance of O-rings and elastomer seals by averting extrusion. Available as solid, scarf cut, or spiral rings, these retainers harness our exclusive Quantum® materials, meeting AMS-3678 standards. They significantly extend seal lifespan, particularly in high-pressure and extreme temperature environments, ensuring heightened reliability.

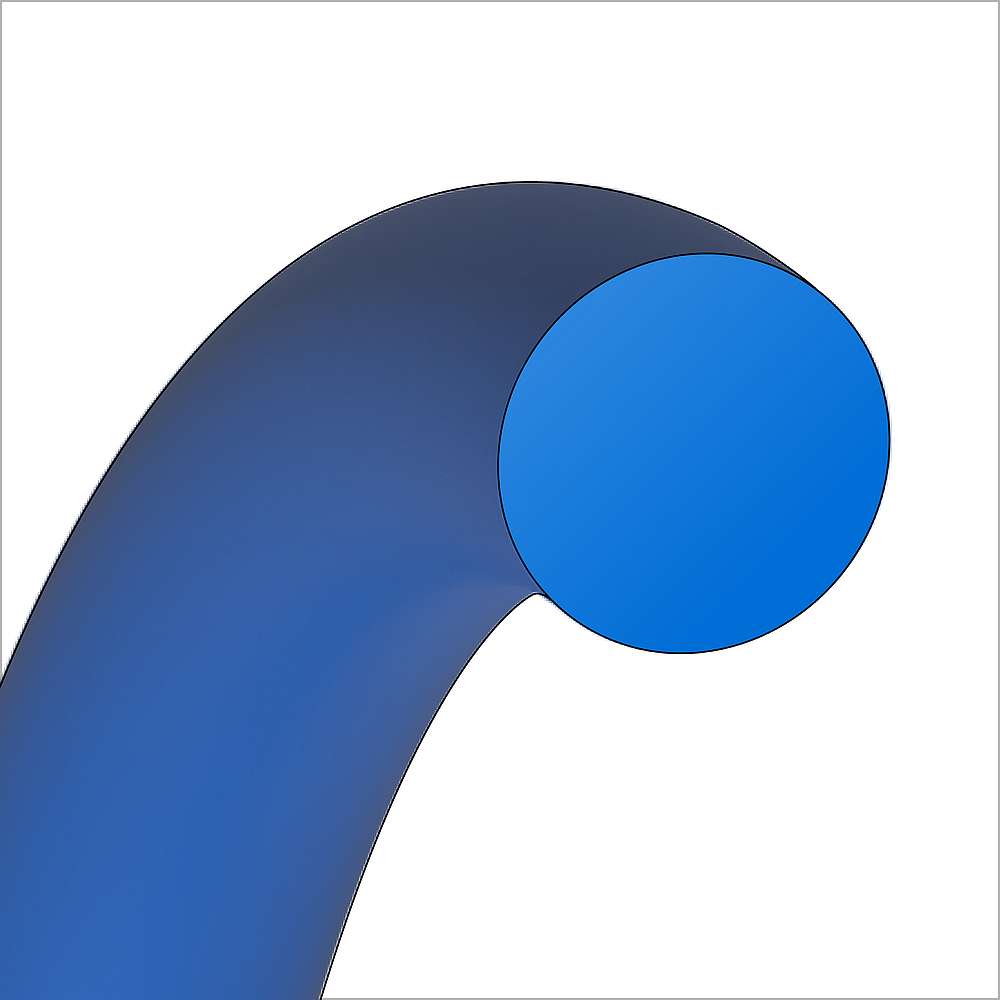

Kiss-Seals

Freudenberg Kiss-Seals: low-friction, durable sealing solutions ideal for rotating aircraft components.

Safeguarding Engine Components

Our proprietary materials provide robust protection for engine and nacelle components, shielding against extreme heat and fire. These thermal barriers seamlessly integrate with the substrate or function as blankets, utilizing elastomer, plastic, and/or composite constructions. Lightweight and cost-effective, they offer efficient customer safeguarding solutions.

Enhancing Airframe Integrity

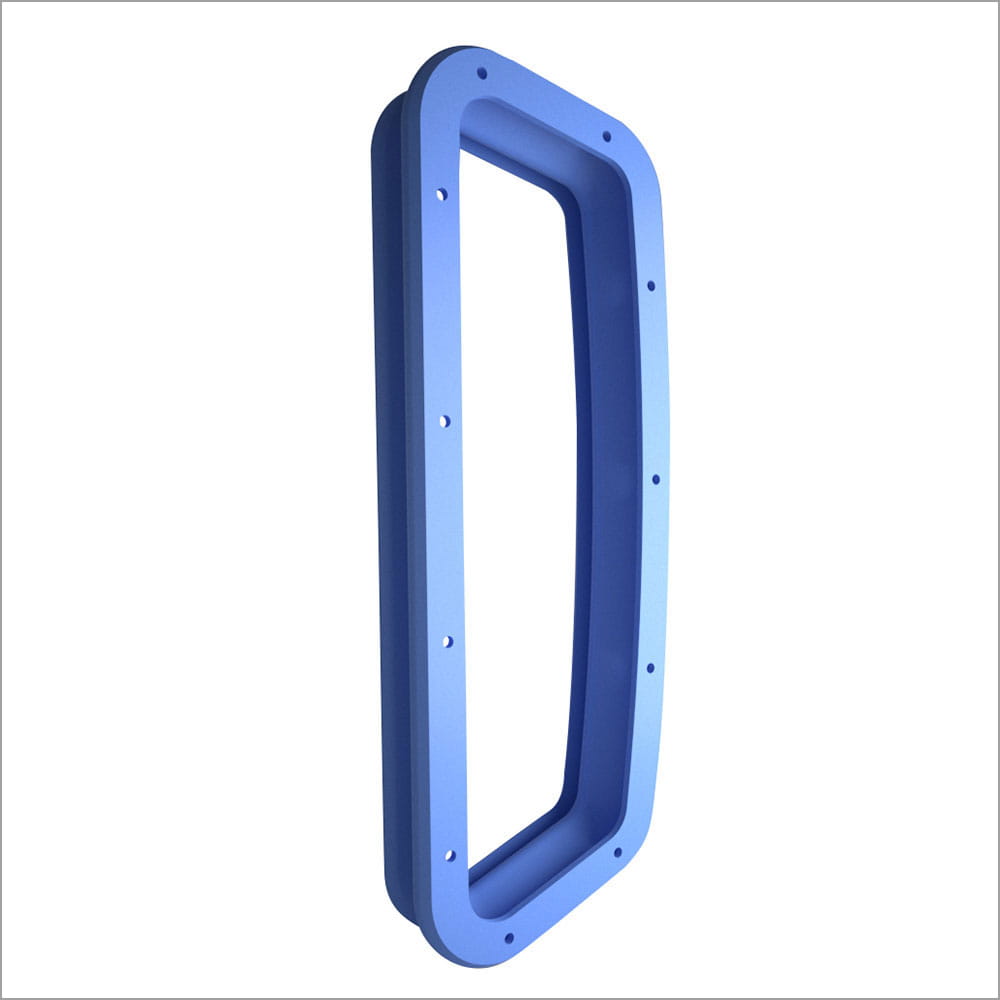

Our innovative designs and materials provide comprehensive airframe sealing, ensuring coverage for cabin pressure zones such as doors, windows, hatches, and high-performance seals on flight control surfaces. With proprietary low-friction, abrasion-resistant, and low-density materials, we enhance our customers' efficiency and reliability goals, contributing actively to their objectives.

Door Seals

Aircraft door seal from Freudenberg Sealing Technologies, ensuring airtight closure, cabin pressure stability, and passenger safety.

Adaptable Sealing Solutions

Our silicone tape forms an airtight, watertight seal around electrical connections, bonding permanently within 24 hours. With no-adhesive technology, it allows easy, clean re-entry without substrate bonding. Additionally, it's available with fabric reinforcement, enhancing tear resistance and flame retardancy, ideal for applications requiring durability, such as hot air ducting.

Tailored Protection Solutions

Our bespoke grommet designs guarantee exceptional protection for pass-through assemblies, securing wires, tubes, ignitors, connectors, and compressor vanes. These designs offer comprehensive defense against electrical, chafing, thermal, impact, and vibration risks. Moreover, they ensure effective gas/fluid sealing and, when necessary, fireproof capabilities, addressing diverse application requirements.

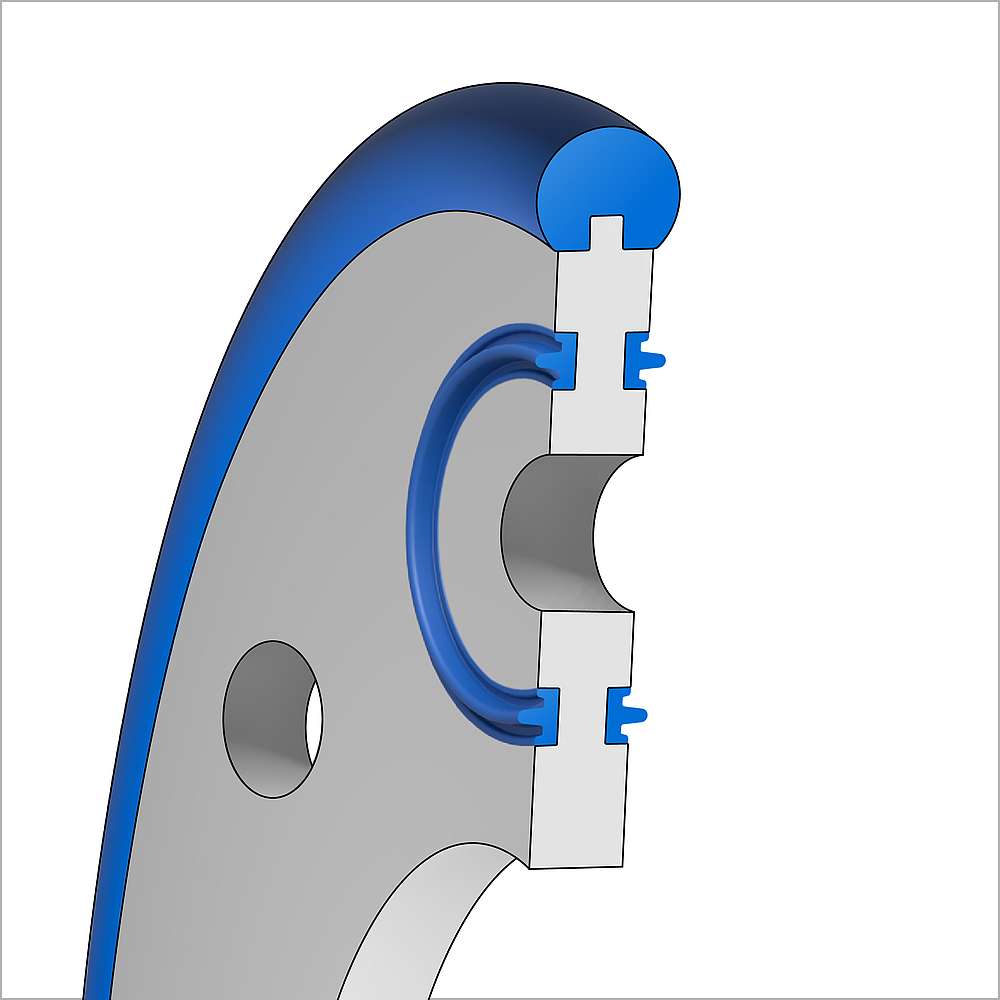

Engine Vane (Grommet)

The Vane Grommet is a component used in turbine engines, designed to secure and insulate the vanes within the engine assembly. It ensures proper alignment and reduces vibration, contributing to the overall stability and efficiency of the engine.

Clamp Blocks

Clamp Blocks are components used to secure and organize tubing and wiring in aerospace applications, ensuring stability and protection against high-vibration and extreme temperature conditions. They are essential for maintaining the integrity and performance of various aerospace systems.

What Types of Engines Are There in Commercial Aviation?

In commercial aviation, large long-haul jets are mainly used to transport passengers and freight, but smaller regional aircraft are also used. While large commercial aircraft are mainly powered by turbofan engines, regional aircraft also fly with turboprop engines. Rotor-based applications such as helicopters are powered by turboshaft engines.

Requirements of Turbofan, Turboprop and Turboshaft engines

The requirements for seals and materials vary considerably depending on the type of engine. The engines used in modern aviation were developed for specific applications.

How do modern turbofan engines work?

Modern turbofan engines are highly complex systems that are essential for the reliable and efficient propulsion of commercial aircraft. A large fan is used in these engines, which draws in the ambient air and divides it into two main streams: One part supplies the engine core, while a large proportion is routed around the core as bypass air to increase efficiency. In the core, several compressor stages ensure that the intake air is compressed before it is mixed with fuel in the combustion chamber and ignited. The resulting hot gases drive the mechanics of the engine in the turbine and supply the energy that keeps the compressor and fan moving. In addition, some of the compressed air is diverted as bleed air to support important aircraft systems such as cabin air, de-icing or hydraulic and pneumatic systems.

Requirements for seals

- High temperatures in the combustion chamber.

- Chemical resistance to kerosene and oils.

- Precise rotary seals for high speeds.

Application examples

Long-haul jets such as the Airbus A350, Boeing 787 and medium-haul aircraft such as the Airbus A320 and Boeing 737MAX.

How does a turboprop engine work?

A turboprop engine combines the efficiency of a propeller with the power of a gas turbine. Unlike a turbofan, the main thrust is not generated by the hot exhaust jet, but by a large propeller driven by a turbine.

The air is first drawn into the engine by a compressor and compressed there. Kerosene is injected into the combustion chamber and ignited, producing hot gases. These gases drive a turbine, which in turn turns the propeller shaft via a gearbox. This sets the propeller in motion and generates most of the thrust. Turboprop engines are particularly efficient at lower flight speeds (up to approx. 800 km/h) and are therefore ideal for short and medium-haul flights with regional aircraft. They offer low fuel consumption and good take-off and landing performance, which also makes them attractive for smaller airports with short runways.

Requirements for seals

- Vibration resistance.

- Moderate temperatures.

- Lightweight seals to save weight.

Application examples

Regional aircraft such as the ATR 72 or Bombardier Dash 8.

How does a turboshaft engine work?

A turboshaft engine is based on the principle of a gas turbine engine, but is specially designed to generate mechanical energy instead of direct thrust. It is mainly used in helicopters and certain industrial applications such as power generators or marine propulsion systems.

The way it works is similar to that of a turboprop engine: air is drawn into the compressor, compressed and mixed with kerosene in the combustion chamber. The resulting hot gases drive a turbine stage which, however, does not use the energy to generate an exhaust jet, but turns a drive shaft via a gearbox. This shaft transmits the power to the main rotor of a helicopter or other mechanical systems.

A decisive advantage of the turboshaft engine is the independent power output: the freewheel turbine can rotate independently of the main turbine, which enables precise control of the propulsion power. This enables smooth, efficient and flexible power adjustments - an essential factor for helicopters that require frequently varying power during flight.

Requirements for seals

- Mechanical strength and wear resistance.

- Oil tightness for transmission components.

- Heat resistance for moderate temperatures.

Application examples

Helicopters such as the Sikorsky S-92 or Airbus H145.

Critical Engine Components: Thrust Reverser, Nacelle and Pylon

How do innovative sealing solutions protect engine components?

In addition to the drive components, there are other essential parts that ensure the functionality and efficiency of an engine. These include the thrust reverser systems, which apply a targeted redirection of thrust in order to increase the braking effect during landing. The engine cowling, known as the nacelle, encases the engine, protects it from thermal influences and optimizes aerodynamics. Pylons securely connect the engine to the aircraft fuselage. Essential components such as fuel lines, hydraulic and electrical systems run through them. They must therefore be able to withstand high temperatures, extreme mechanical loads and vibrations, while at the same time being as light and aerodynamic as possible.

These key areas place special demands on seals and materials: from thermal protection to vibration resistance and lightweight construction. Freudenberg Sealing Technologies offers customized solutions that meet these challenges while ensuring maximum safety and efficiency.

Materials for Aerospace

Pioneering proprietary formulations, meticulously crafted in-house, exceed customer requirements.

How Does an Aircraft Engine Work During Flight?

A flight begins long before takeoff. Invisible but essential, countless components work together to prepare the engine for each phase. Heat, pressure, rotation – a highly complex system that functions only through precise engineering and reliable sealing solutions.

-

How is an aircraft engine prepared before takeoff?

-

How does an engine generate thrust during takeoff?

-

Why do engines operate more efficiently at high altitudes?

-

How does engine performance change during descent?

-

What happens to an engine after landing?

-

How does an engine remain reliable in every phase of flight?

How is an aircraft engine prepared before takeoff?

The aircraft is still at the gate. The auxiliary power unit (APU) starts up, providing electricity and compressed air. The main engines are ready – air is flowing into the compressors, and the fuel lines are filling. Seals perform their first crucial task: they containing the compressed air, preventing leaks, and ensuring a safe fuel supply. One last check – then the first engine ignites with a powerful hiss.

How does an engine generate thrust during takeoff?

The throttles move forward – the engine unleashes its full power.

- Air is compressed and temperatures rise above 1,000°C.

- Fuel ignites, and the expanding gases drive the turbine.

- Thrust is generated, propelling the aircraft forward until it lifts off.

Extreme forces act on every component. Heat-resistant seals protect the combustion chamber and high-pressure lines, while rotary seals keep oil precisely where it is needed.

Why do engines operate more efficiently at high altitudes?

High up in the thin air, the engine runs smoothly. Now, the focus shifts to minimizing losses and maximizing efficiency.

- Bypass airflow optimizes fuel consumption.

- Aerodynamic seals reduce air leakage and vibration.

- Temperature-resistant materials protect delicate components.

Behind the scenes, specialized sealing systems keep the engine running optimally – hour after hour, mile after mile.

How does engine performance change during descent?

As the aircraft descends, thrust decreases, and air pressure and temperature change. Elastic seals compensate for material stress, maintaining performance and safety.

On landing, thrust reversers abruptly redirect the exhaust stream – an extreme mechanical challenge. Fire-resistant and high-pressure seals must withstand this stress in mere fractions of a second to ensure smooth operation.

What happens to an engine after landing?

At the gate, the engines shut down, while airflow dissipates residual heat. Corrosion-resistant seals protect the systems until the next flight.

How does an engine remain reliable in every phase of flight?

An engine is subjected to extreme stresses, from the explosive thrust of the takeoff to precise control of landing. Each phase requires perfectly coordinated mechanisms, supported by invisible yet essential helpers: sealing solutions.

Aerospace News

Services for Aerospace

Ready for the next generation of aviation?

Put your trust in our sealing solutions that meet tomorrow's requirements today. Talk to us about your individual requirements. Together we will shape the future of aviation

Contact us