Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

21.01.2020 | Press release

Accurate Long-Term Predictions

Weinheim (Germany). January 21, 2020. The static seals used in large energy and industrial facilities can be challenging to install and difficult to replace. They must, therefore, function flawlessly for periods longer than 20 years. Up until now, the existing tools used to calculate the long-term performance of sealing materials for these kinds of applications have often led to the components being larger than actually necessary. Freudenberg Sealing Technologies has now developed a method that takes material changes at the molecular level into account when predicting the long-term durability of seals. The new methodology is more reliable than previous models and ensure fewer materials to be used.

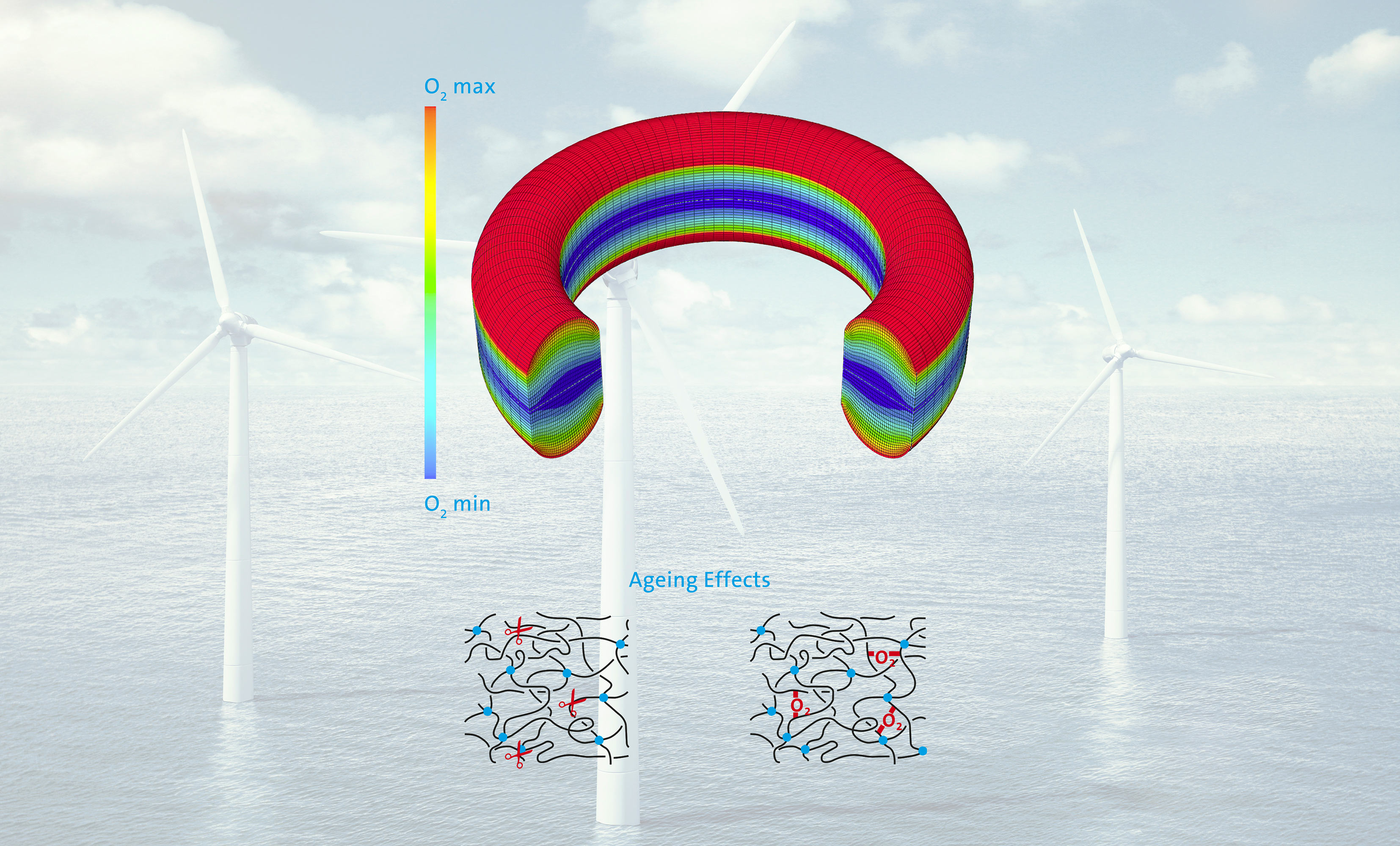

The seals used in plant engineering must have a very long service life. Once they are installed – to protect offshore wind turbine towers from salt corrosion, for example – customers (typically) require that they perfectly for more than 20 years. The service life of a seal is limited on the one hand by setting or stretching (physical relaxation). On the other hand, the material loses its elasticity over time due to chemical changes. Under the influence of atmospheric oxygen or ozone, two basic effects that influence the aging of seals can be observed: First, the polymer chains and networks can fracture under mechanical stress, and second, additional oxygen bridges can develop in the network as a result of oxidation processes. Both effects influence important properties of relevance for seals such as stiffness, contact pressures or the ability to regain their original shape after deformation, also referred to as resistance to deformation.

Extrapolation with the Arrhenius Equation

To determine whether a material actually meets the requirements for a specific application, engineers usually conduct so-called “storage tests” in which the test specimen is exposed to temperatures well over 100° C for a longer period of time – usually 1,000 hours – to predict temperature-dependent aging. Engineers typically extrapolate the measured values using the Arrhenius Equation, a method named after the Swedish chemist and Nobel Prize winner Svante August Arrhenius. The equation is a formula for the temperature dependence of reaction rates where an increase in temperature by 10 °C leads to a doubling of the reaction rate. This enables predictions to be made using accelerated aging tests at elevated temperatures. When the correct test parameters are chosen, the test method functions reliably. In the absence of correct parameters, however, prediction of service life is inaccurate and can only be checked with measurements that require long testing periods. An improved methodology was required.

Freudenberg’s material experts used a dual approach to develop a new process. They significantly improved the service life model by coupling chemical oxidation equations – for example, the oxygen attack on the elastomer – with the structural-mechanical behavior of the material. In order to efficiently calculate any possible geometry, the new method was numerically based and employed a commercial finite element program. It is now possible to calculate local oxidation processes and their effect on materials’ mechanical behaviors using the Freudenberg method.

At the same time, Freudenberg experts also further developed the measurement methods used to determine the parameters for the material model – to calculate the amount of oxygen consumed during the aging process, for example. The amount of oxygen is an important parameter for estimating the extent of the chemical attack.

Joint Development with Freudenberg Technology Innovation

“Thanks to the improvement of the measurement methods as well as the material model and the applicability to three-dimensional components, a precise method for predicting the service life has now been developed,” said Dr. Boris Traber, who is responsible global advance material development at Freudenberg Sealing Technologies.

The process was developed jointly with Freudenberg’s corporate research department, Freudenberg Technology Innovation, and was first verified on material samples with different diameters. It is now being applied to initial applications including construction of offshore wind turbines. Traber sees this as only the beginning of a new simulation era, however.

“In the future, we will be able to provide our customers in plant construction with a reliable best-before date even over very long periods,” he said.

At present, a library with models for various materials and component geometries is being set up. At the same time, simulation is being expanded so that application-specific cycles with changing temperatures and mechanical loads can also be calculated.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.