Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

02.09.2019 | Press release

Fuel Cells for Long-Distance Bus Transport

Weinheim (Germany), September 2, 2019. FlixBus and Freudenberg Sealing Technologies are collaborating on a future-oriented project for sustainable, CO2-free mobility. Together, Europe's largest operator of long-distance bus travel, the FlixBus brand, and global technology specialist Freudenberg Sealing Technologies are working to put fuel cell-powered coaches on the road. The two companies will further extend their partnership in the near future through participation from a bus vehicle manufacturer. FlixBus and Freudenberg are holding talks to finalize project parameters.

During the past few years, the bright green FlixBus buses have grown to become an indispensable part of Europe’s long-distance transportation network. They connect destinations across Europe and carry passengers to roughly 30 countries. Green is not only the color of their buses and trains. The modern long-distance buses of the FlixBus fleet are one of the most environmentally friendly means of transport. The same applies to FlixTrains, which operates on 100 percent green electricity. Collaboration between FlixBus and Freudenberg will take these even further, said Fabian Stenger, Managing Director of FlixBus DACH. "We want to help shape the future of mobility,” Stenger noted. “The modern FlixBus and FlixTrain fleet is already extremely environmentally friendly. Nevertheless, we are constantly asking ourselves how we can make travel even more sustainable and further reduce CO2 emissions per capita. Following the successful launch of three electric long-distance buses, we now want to develop the first long-distance bus with fuel cell drive together with Freudenberg and set another milestone in the history of mobility."

Against the background of ever-stricter CO2 limits, Freudenberg Sealing Technologies has been helping car and commercial vehicle manufacturers address fuel consumption and emissions requirements with innovative sealing solutions for decades. At the same time, the Freudenberg Group began researching alternative drive concepts as early as the mid-1990s, developing technically sophisticated components for fuel cells and batteries.

Strategic acquisitions

In early 2018, Freudenberg Sealing Technologies further strengthened its fuel cell expertise by acquiring a fuel cell manufacturer. During the same period, the company also expanded its technological expertise in battery technology by acquiring a minority interest in US battery manufacturer, XALT Energy. Freudenberg Sealing Technologies now holds a majority stake in the company.

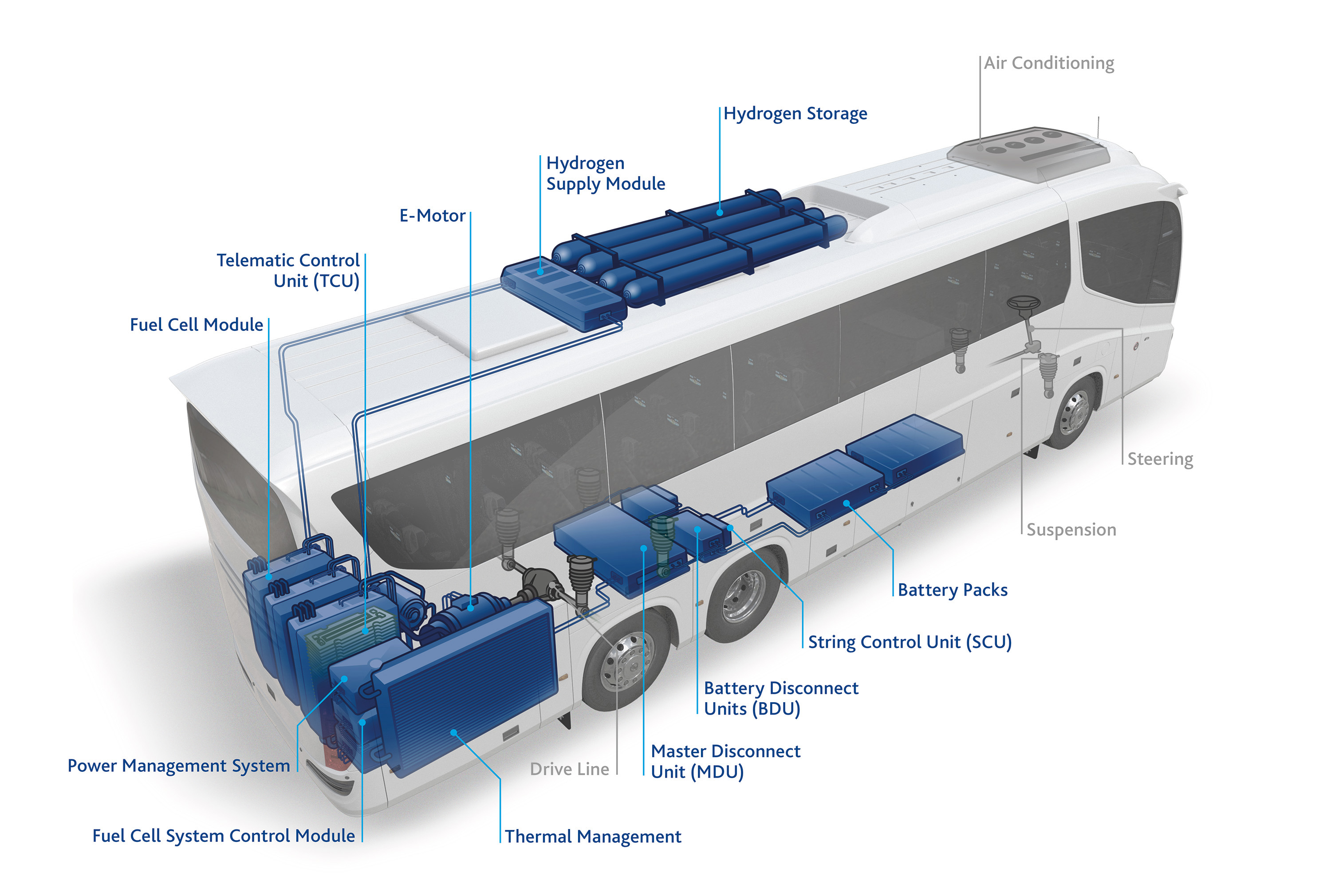

These strategic acquisitions have solidified Freudenberg Sealing Technologies’ position as an excellent provider of fuel cell and electric battery powertrain solutions. The company is pursuing integrated battery-fuel cell systems that will address power, base load and unique operating cycles in a range of heavy-duty applications that include truck, bus, commercial marine and rail transportation. Through unique vertical integration, Freudenberg Sealing Technologies will become a single source supplier of complete battery, fuel cell and hybrid energy systems that include all of the components, modules and subsystems necessary for their operation.

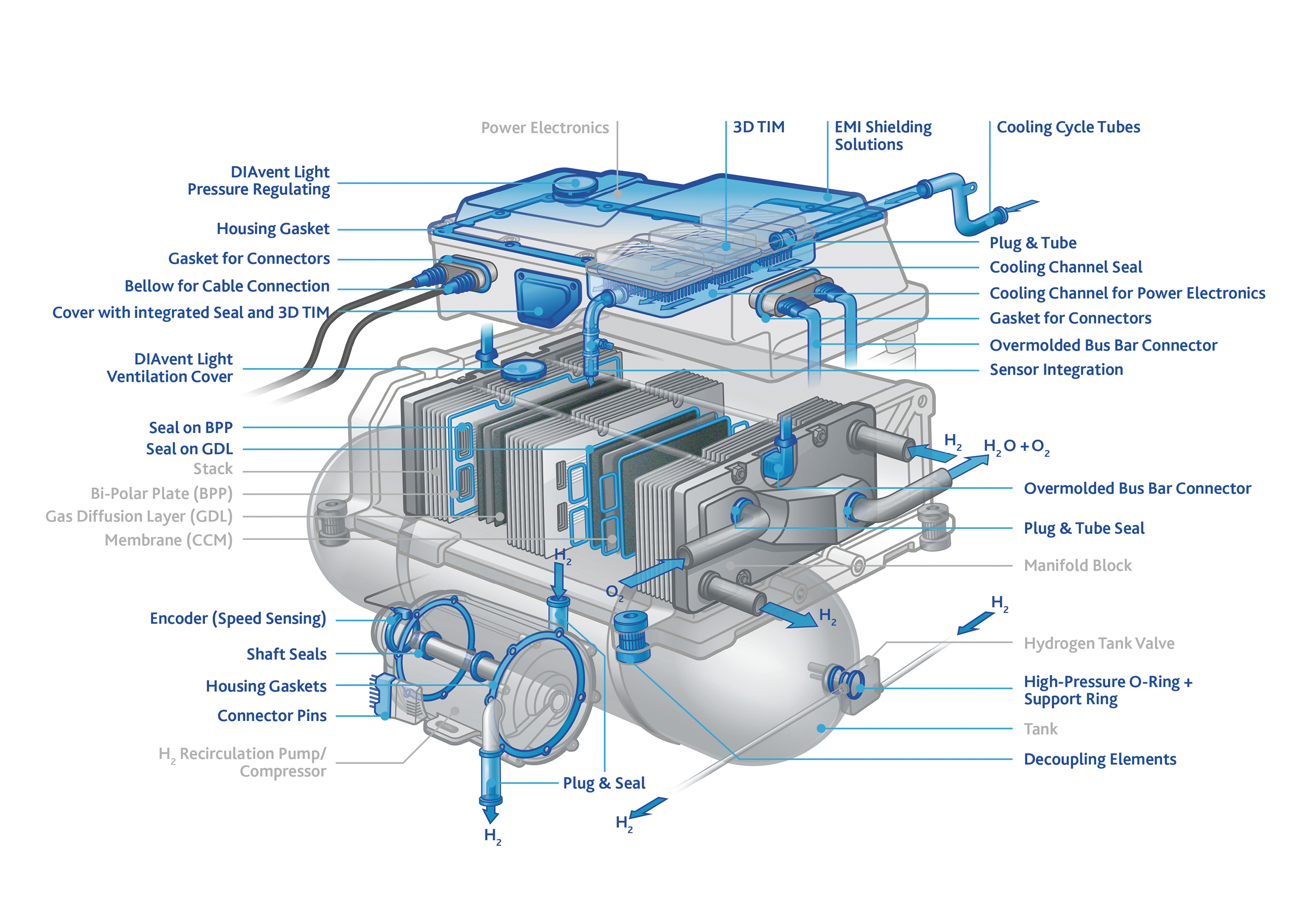

This gives Freudenberg Sealing Technologies an industrywide, unique in-house depth of value added in both batteries and fuel cells. This ranges from the separator to the cell to the complete battery system or from the gas diffusion layers (GDL) to the membrane electrode assembly (MEA) and the stack to the finished fuel cell. The modular systems can be customized to accommodate different performance requirements that offer customers better efficiency, value and total cost of ownership opportunities for their unique circumstances.

Clear requirements

"The technical requirements for performance and long-term reliability are particularly high in heavy-duty businesses. This is in line with our technological and innovation expertise," says Claus Möhlenkamp, CEO of Freudenberg Sealing Technologies. "We see the fuel cell in combination with electric batteries as an integral part of the mobility of the future. With FlixBus, we have found a partner for this zero-emission application and are looking forward to working together on this groundbreaking project.”

FlixBus has clearly defined the requirement profile for its vehicles. Performance characteristics such as acceleration should correspond to those of today's diesel-powered, long-distance buses that are compliant to the Euro IV standard. These fuel cell vehicles should cover at least 500 kilometers of continuous use without refueling. Hydrogen refueling, itself, should be possible in 20 minutes or less – a time similar to what is required to refill a diesel fuel tank.

The hybrid system, which intelligently combines battery and fuel cells, can be used in long-distance bus transportation and heavy commercial vehicle applications. Initially, a representative bus fleet of 30 vehicles will be equipped with a hybrid powertrain to validate system performance. The two companies are also aiming for public funding within the framework of the German "National Innovation Program Hydrogen and Fuel Cell Technology" (NIP). The aim is to ensure that this technology quickly reaches market maturity and thus makes a significant contribution to reducing CO2 emissions in the atmosphere.

"The electrification of drive technology is making huge strides. We are therefore pleased that with FlixBus we have another well-known customer that relies on our innovative strength and quality," Möhlenkamp concluded.

What is being set in motion with Freudenberg and FlixBus in Europe could well travel to new continents and eventually encompass clean rail transportation as well.

Press Release Downloads

Download Images

Claus Möhlenkamp

JPG | 4.1 MB

Download

JPG | 2.48 MB

Download

FST Freudenberg FlixBus Bus

Copyright 2019, Freudenberg Sealing Technologies | JPG | 2.7 MB

Download

FST FuelCell Bus Illustration

Copyright 2019, Freudenberg Sealing Technologies | JPG | 870 KB

Download

FST Freudenberg FlixBus Fuel Cell System

JPG | 1.44 MB

Download

FST Freudenberg FlixBus Fuel Cell System Illustration

JPG | 2.17 MB

DownloadUlrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.