Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Cover Seals

Gasket O-Ring Seal - Operating Pressure Always Looks for a Way Out

Cover Seals From Freudenberg Sealing Technologies

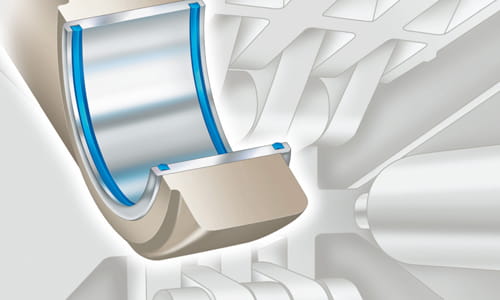

Even if machine elements under pressure are firmly bolted to one another, there is still a so-called static seal gap that must be sealed. O-Rings – or O-Rings with back rings for improved extrusion stability – are most commonly used. If the requirements are more specialized, one-piece sealing elements made of polyurethane come into use. For example, the requirements may involve gaps for breathing due to major pipe expansion, short pressure rise times or alternating operating pressures. Freudenberg Sealing Technologies offers the most suitable cover seal for any application. They stand for the highest possible operating security and extrusion stability.

Simple and Secure Mounting

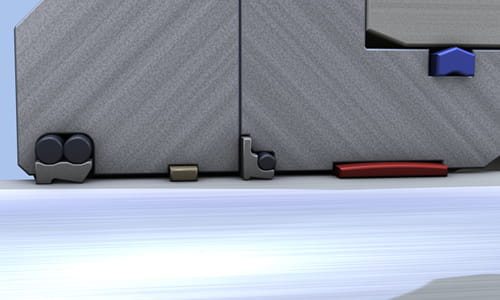

Polyurethane material offers outstanding characteristics relating to robustness and form stability – above all, to resist extrusion. As a result, even complex geometries can be manufactured with injection molding or even with turning technologies if a quick delivery is needed. This characteristic makes it possible to use one-piece seals. This especially offers an advantage during mounting since any potential inverted position – as in an O-rings/back ring combination – can be precluded. The profile rings are designed in such a way that they can even be substituted in existing installation spaces for O-ring/back ring systems (Fig. 1).

The high linear force on the seal edges of polyurethane seals also enables their use in related applications. Merkel® Pinmatic is produced with only slight changes in its geometry. It provides the best possible performance in virtually static applications such as knee lever systems or the bearing or joint bolts of injection molding machines (Fig. 2).

Our Products in Detail

Merkel® Cover Seal PU 82

One-piece, dual-action compact seal made of polyurethane. Internal sealing. High operating reliability and extrusion stability. Suited to existing O-ring installation spaces as well as those for O-rings with a back ring.

Merkel® Cover Seal PU 83

One-piece, dual-action compact seal made of polyurethane. Internal sealing. High operating reliability and extrusion stability. Suited to existing O-ring installation spaces as well as those for O-rings with a back ring.

Merkel® Pinmatic

One-piece, dual-action compact seal made of polyurethane to seal joint bolts. Internal sealing. Insensitive to pressure peaks.

Merkel® Stircomatic SRC

One-piece compact seal made of polyurethane for high operating pressures up to 80 MPa. High operating reliability and extrusion stability. Simple, secure mounting.

O-Rings

Usage mainly for sealing stationary machine parts against liquid and gaseous media. Under certain conditions, their use as a dynamic sealing element is possible when the movements are axial, rotating and oscillating.

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Related Topics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new