Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Rod Seals

High-performance rod seals for hydraulic cylinders – precise sealing, maximum efficiency

How modern sealing systems from Freudenberg Sealing Technologies boost performance, extend service life, and improve energy efficiency

For safe, energy-efficient, and long-lasting operation of hydraulic cylinders, a high-performance rod sealing system is essential. The rod seal reliably retains the operating fluid inside the cylinder and prevents the ingress of dirt, moisture, or dust. Even under high system pressures, heavy dynamic loads from alternating movements, and extreme environmental conditions, sealing solutions from Freudenberg Sealing Technologies ensure maximum functional reliability. Our rod seals combine technical precision with long service life – engineered for global use in industrial, mobile hydraulic, energy, and process applications.

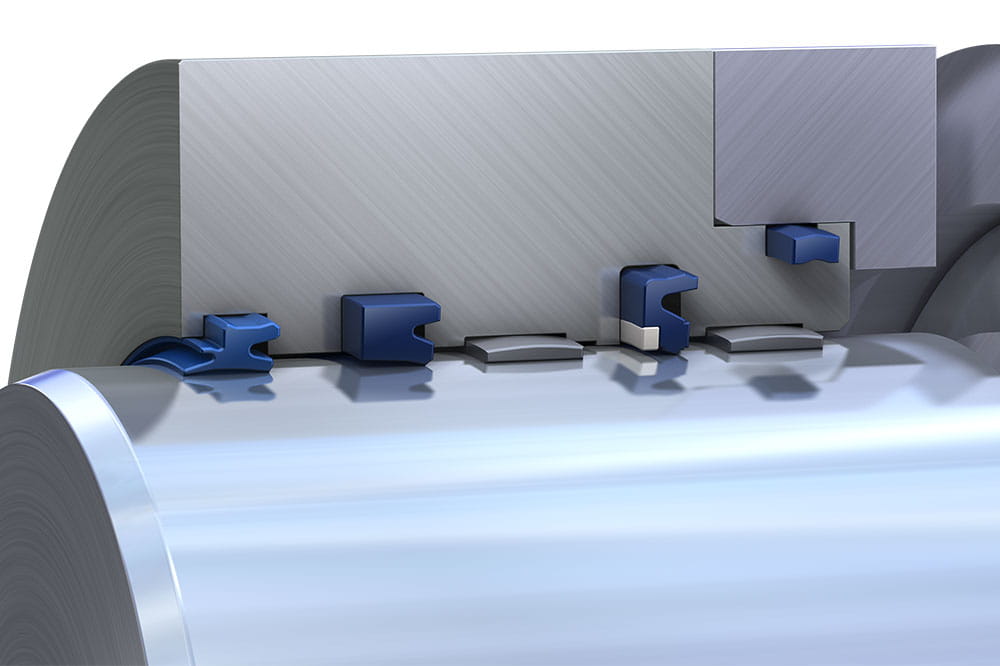

What is the design of a modern rod sealing system?

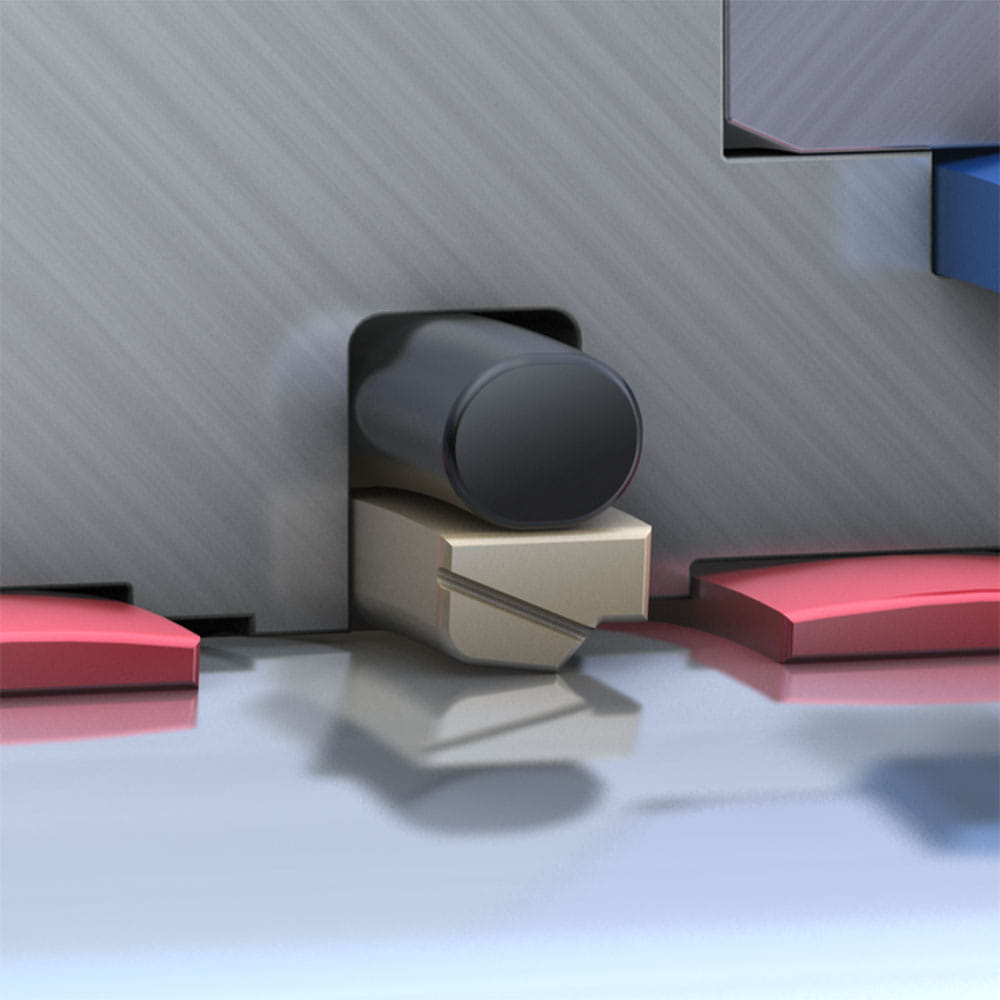

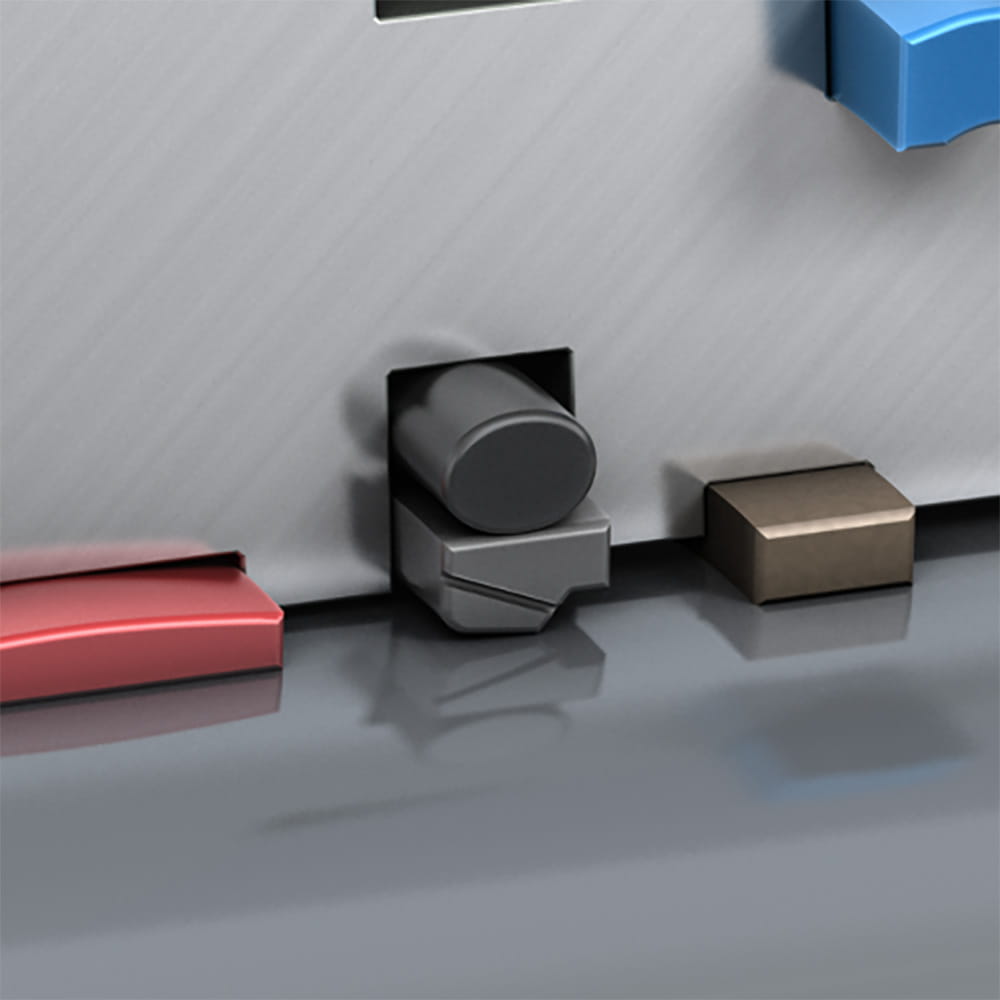

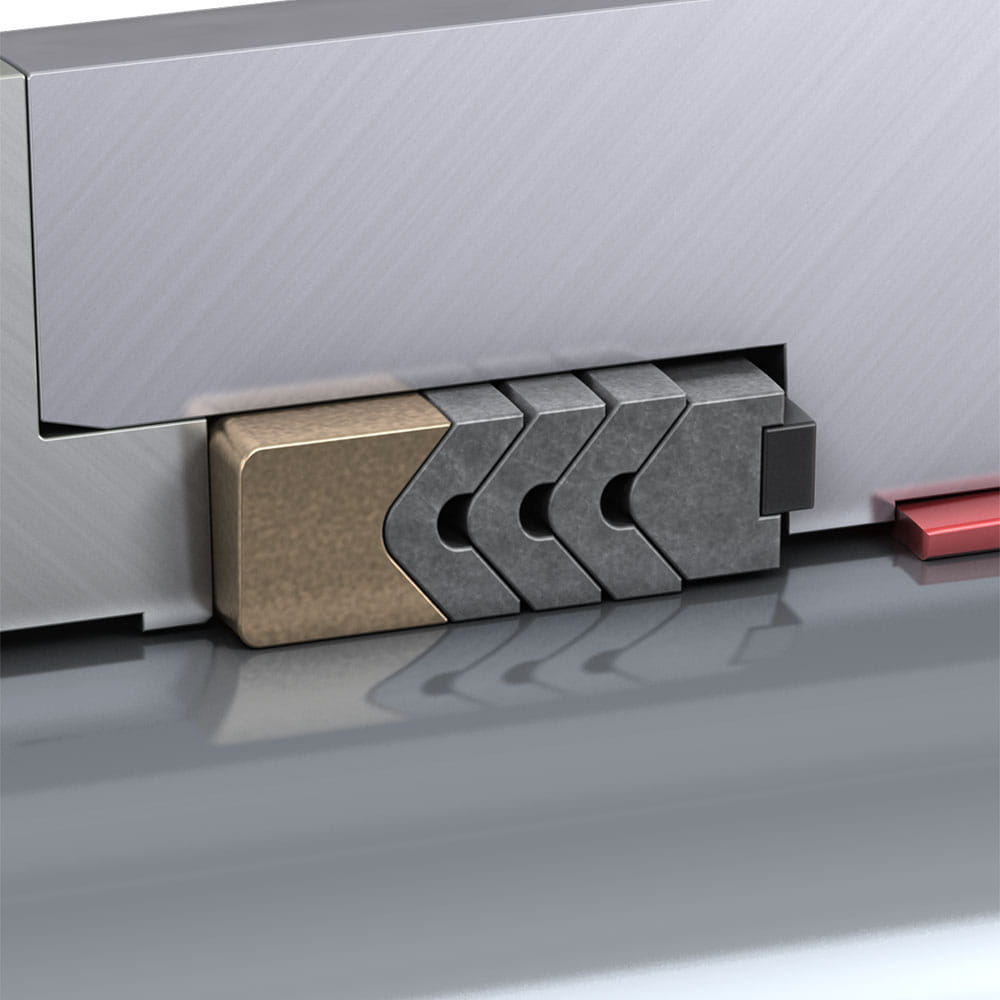

A modern rod sealing system for hydraulic cylinders – as shown in the illustration on the right – consists of several perfectly matched components:

The Primary Seal

Located on the pressure side of the cylinder, facing the working chamber, the primary seal ensures reliable sealing against operating pressure and pressure peaks. For this demanding task, various high-performance seals are available – optionally with integrated pressure-relief functionality for maximum efficiency and service life.

The Secondary seal

Positioned behind the primary seal, the secondary seal minimizes the remaining oil film on the piston rod during extension. Seals with a defined sealing lip are used for this purpose, finely wiping the medium and ensuring external tightness of the hydraulic cylinder.

The Guide Element

Guides stabilize the piston rod, absorb transverse forces, and prevent direct metal-to-metal contact between moving and stationary components.

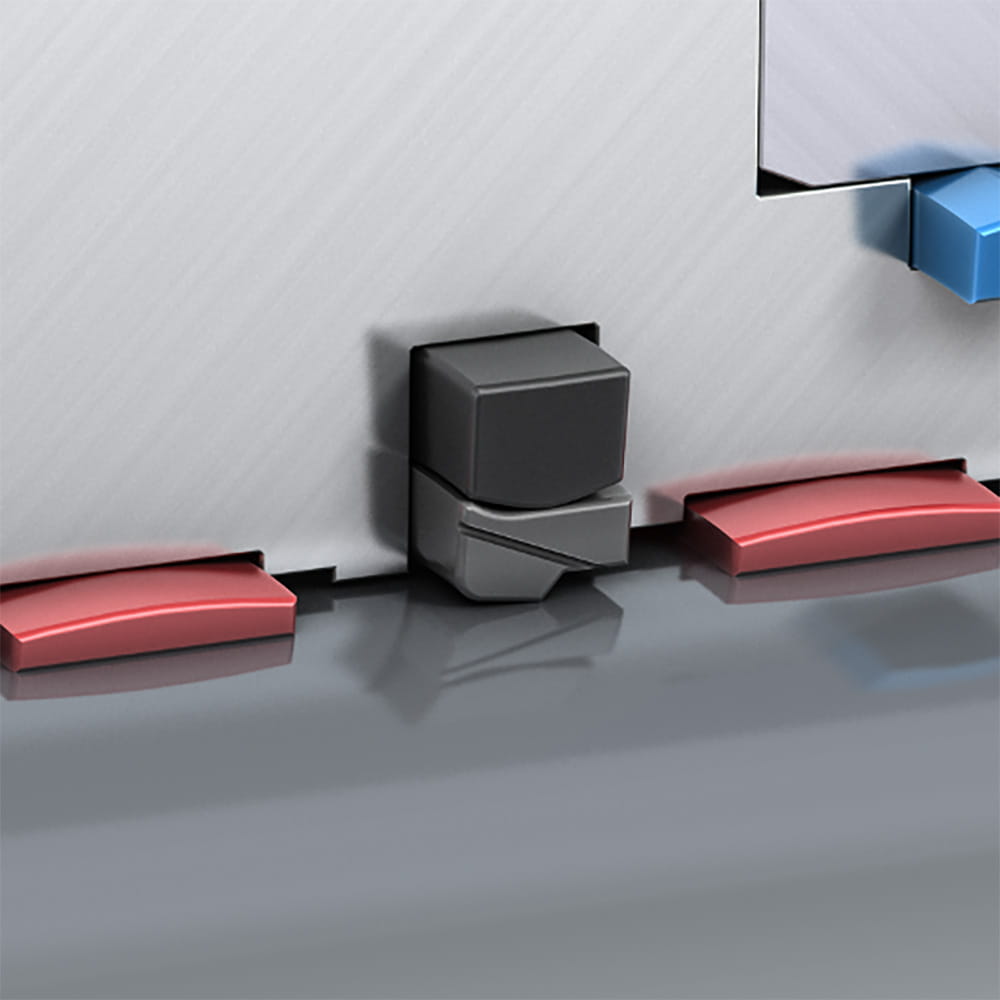

The Wiper

Located at the outer edge of the cylinder housing, it reliably protects the sealing system against dirt, moisture, and particles. Depending on the design, it can also provide a secondary sealing function, further increasing the operational safety of the hydraulic cylinder.

Only the perfect interaction of these elements guarantees maximum efficiency, low friction, and long service life of the hydraulic system.

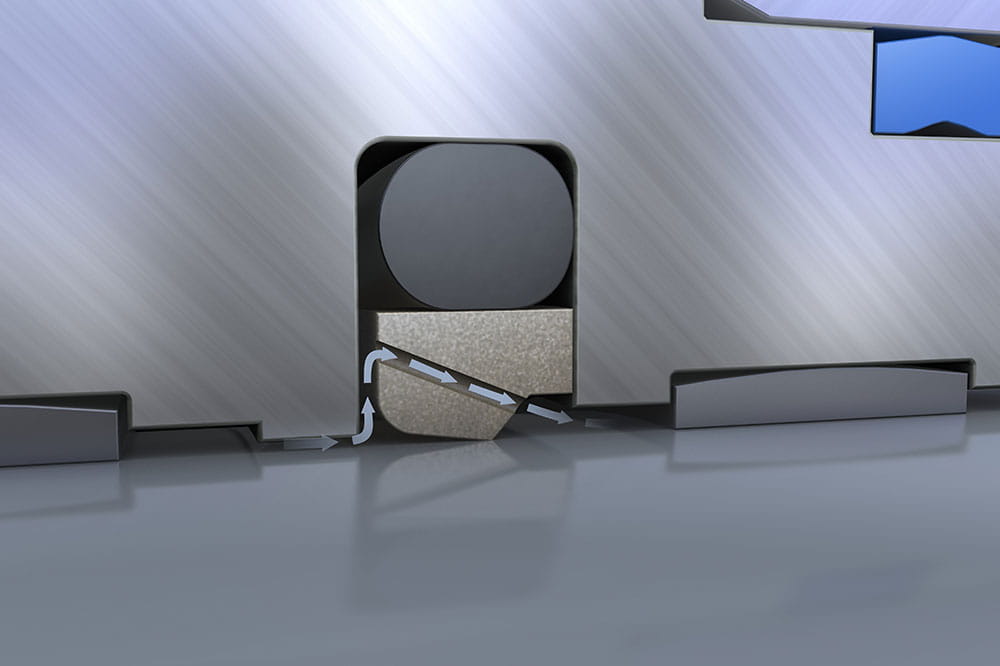

Pressure relief in sealing systems – a must, even beyond long strokes

Large stroke movements, vibrations, or highly variable extension and retraction speeds of the piston rod can place significant stress on a hydraulic cylinder’s rod sealing system. Under such conditions, operating fluid tends to accumulate in the space between the primary and secondary seals, which – even with good return capability of the primary seal – cannot be transported back into the working chamber.

The result: excessive pressure in this intermediate space, acting on both seals and, in extreme cases, exceeding the system pressure. This can lead to extrusion – where sealing material is forced into the metallic gap under high pressure. In the worst case, parts of the seal tear off, causing complete loss of sealing function.

A pressure-relief function on the primary seal reliably prevents this phenomenon. Once the pressure in the intermediate space reaches a critical level, a valve-like feature enables immediate pressure equalization between the intermediate space and the working chamber.

At Freudenberg Sealing Technologies, different technical concepts are used:

Omegat Rod Seals

Here, a specially integrated pressure-relief bore performs the valve function. In case of overpressure, the seal briefly “floats,” detaches from the groove wall, and opens the bore. This allows the excess pressure to be safely discharged back into the working chamber – quickly and reliably.

Syprim Rod Seal

In this design, a defined tilting motion of the sealing lip provides the pressure-relief function. The excess pressure is directed along the slightly inclined sealing lip and dissipated toward the working chamber.

The result: The seals remain fully functional, and the overall service life of the hydraulic system is significantly increased.

Rod seals – our key designs sorted by material

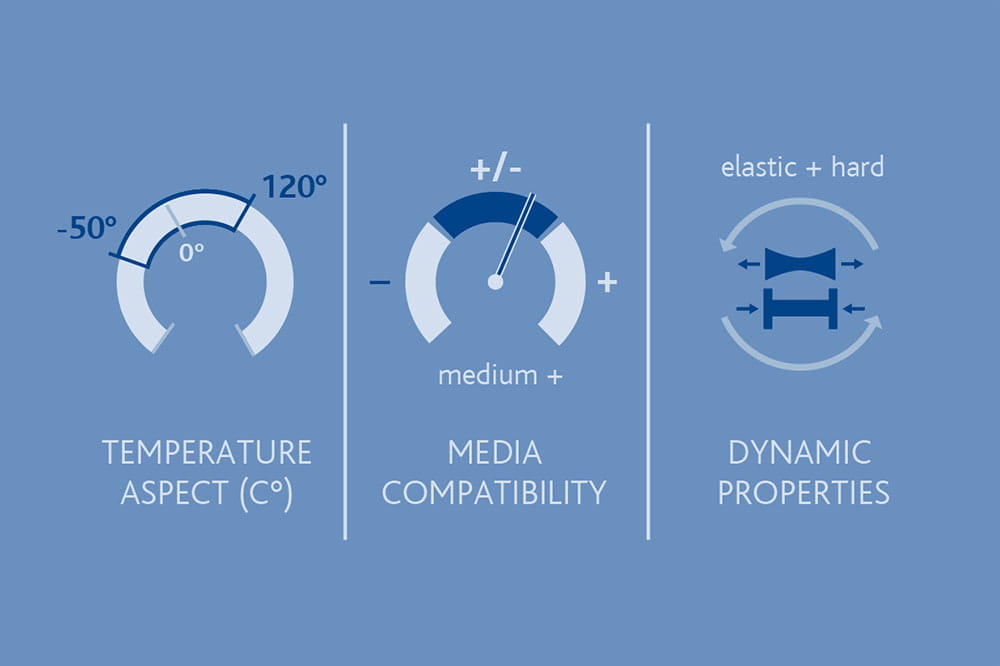

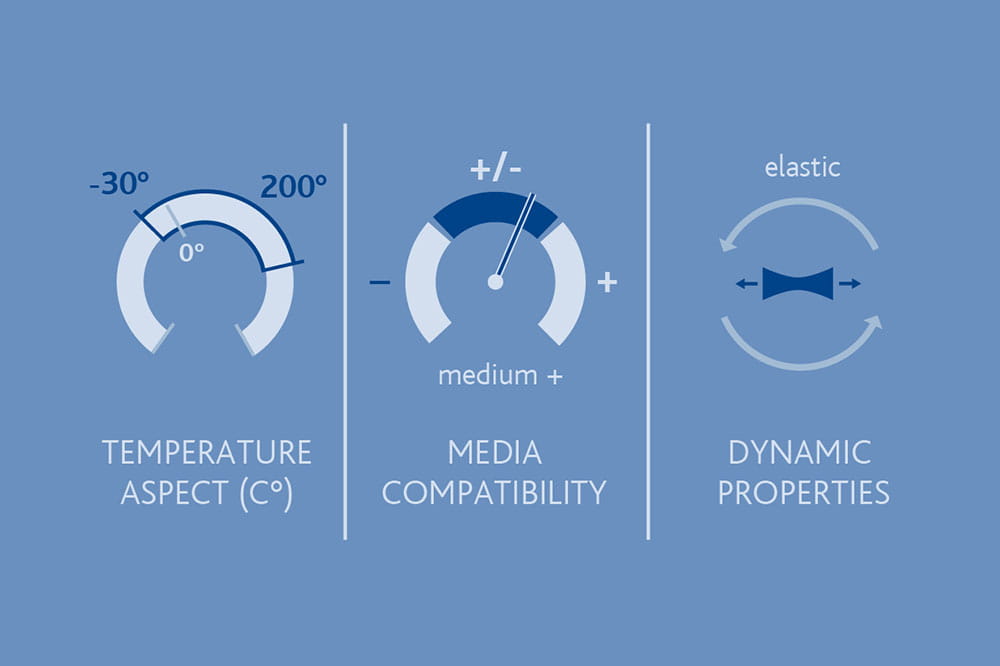

PU – Polyurethane

For more than 60 years, polyurethane has proven to be an ideal material for seals—especially in hydraulic applications. Its outstanding properties include high mechanical strength, excellent elasticity, and exceptional tear and abrasion resistance. This profile is complemented by good media resistance and long service life.

Tailor-made polyurethane sealing solutions are available for a wide range of applications, covering a broad temperature range from -50 °C to +120 °C. In addition, they meet special requirements such as hydrolysis resistance or industry-specific certifications.

Rod seals – our most important designs made of polyurethane

U-ring T20 / TM20

The T20 or TM20 U-ring is a high-performance polyurethane seal with an asymmetric profile for reliable sealing of piston rods. Ideal as a secondary seal in a sealing system, but also suitable for use as a single seal.

-

Long service life thanks to optimized extrusion volume under pressure and a robust PU profile ring

-

High functional reliability even with radial deflection due to large profile overlap

-

Resistant to extrusion even under high operating pressure

-

Easy installation thanks to a one-piece, assembly-friendly sealing element

Note: The T20 variant is predominantly manufactured using the injection molding process for sizes up to approx. Ø 320 mm. TM20 is the machined version, designed especially for large diameters and custom sizes.

Download Product Data Sheet TM20

Download Product Data Sheet T20

LF300

The LF300 U-ring is designed for demanding hydraulic applications. The grooved design ensures extremely low friction values and effectively prevents stick-slip effects. The result: smooth, uniform movement – even at low speeds.

-

Single-acting rod seal suitable for standardized installation spaces according to ISO 5597

-

Excellent static and dynamic sealing performance

-

Versatile applications: Can be used as a primary or secondary seal – ideal for example in industrial trucks

-

Easy installation thanks to a one-piece, simple-to-install sealing element

Download Product Data Sheet

HDR-2C

The HDR-2C is a high-performance U-ring for sealing piston rods. It is made of two chemically bonded polyurethane materials, features an asymmetric profile, and includes an integrated, molded back-up ring that reliably prevents gap extrusion. This ensures operational safety at high working pressures – even when used as a single seal without a primary seal.

-

Suitable for pressures up to 50 MPa and temperatures from -50 °C to +110 °C

-

Material combination for optimal performance: highly elastic polyurethane in the sealing lip area, high-strength polyurethane on the low-pressure side

-

High functional reliability and protection: extrusion resistance allows large sealing gaps while ensuring reliable adjustment during radial deflection

-

Cost-effective: eliminating the need for a primary seal enables a compact, economical sealing arrangement

-

Easy installation: one-piece element prevents assembly errors (Poka Yoke)

-

Fits into standardized installation spaces according to ISO 5597

Download Product Data Sheet

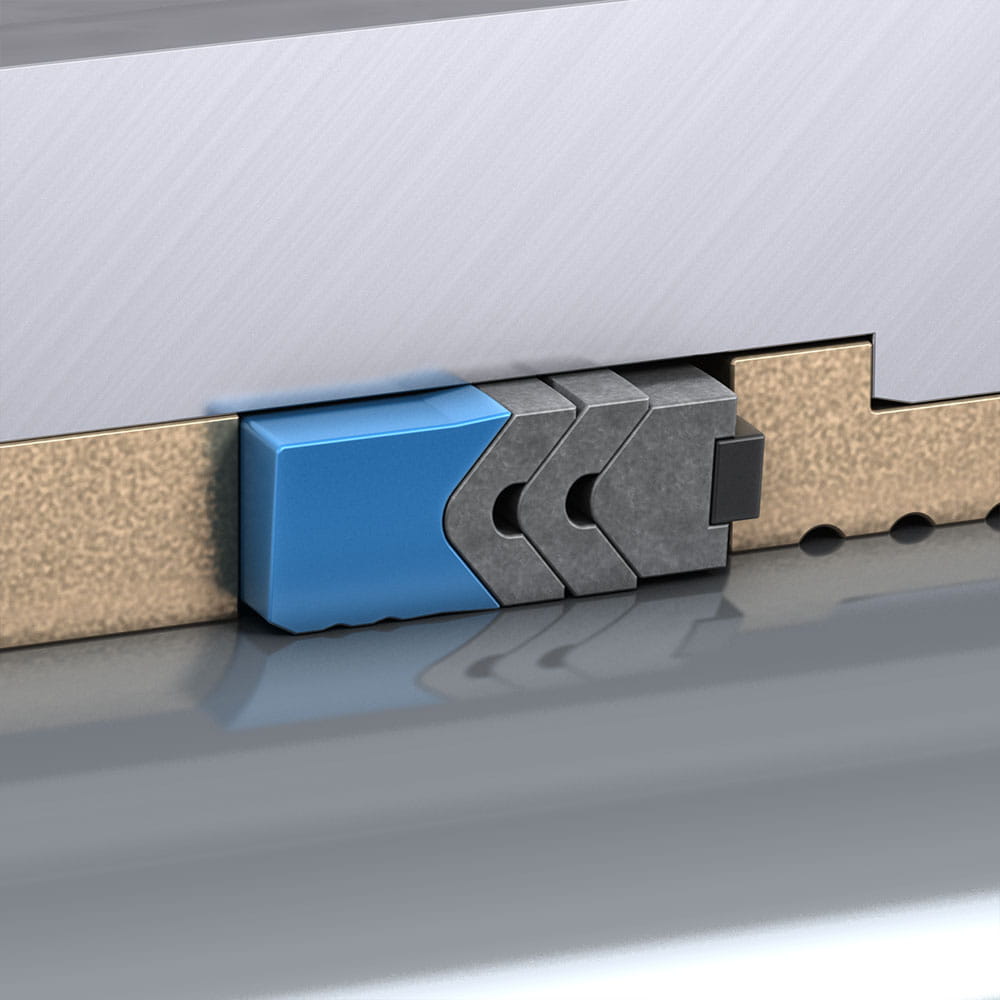

Syprim SM

The two-part Syprim SM sealing set is specifically designed as a primary rod seal within a sealing system. In combination with a U-ring such as the T20, it ensures reliable sealing and optimal functionality in demanding hydraulic applications.

-

Space saving primary seal that can be installed in existing PTFE installation spaces according to DIN ISO 7425-2

-

No excessive pressure build-up between primary and secondary seal thanks to the tilting function of the sealing lip, which reliably relieves pressure into the inner area

-

Low friction, even at low speeds

-

Highly wear-resistant for long service life

-

Extrusion resistance ensured by back-up ring

Download Product Data Sheet

Merkel® Omegat OMSU-MR

Two-piece compact seal with integrated pressure relief function, designed for single-sided pressure application. When combined with a preloading element made of FKM, it is also suitable for higher operating temperatures. The seal is installed in a housing groove and provides a durable, stick-slip-free sealing solution for dynamic operating conditions.

-

Proven seal ensuring top quality, long service life, and reliable operational safety

-

Reliably prevents pressure build-up in the intermediate space of a sealing system during long strokes, vibrations, or significantly varying extension and retraction speeds

-

Outstanding wear resistance and low friction for uniform, stick-slip-free stroke movements

-

Free from potential PFAS restrictions compared to PTFE solutions

Download Product Data Sheet

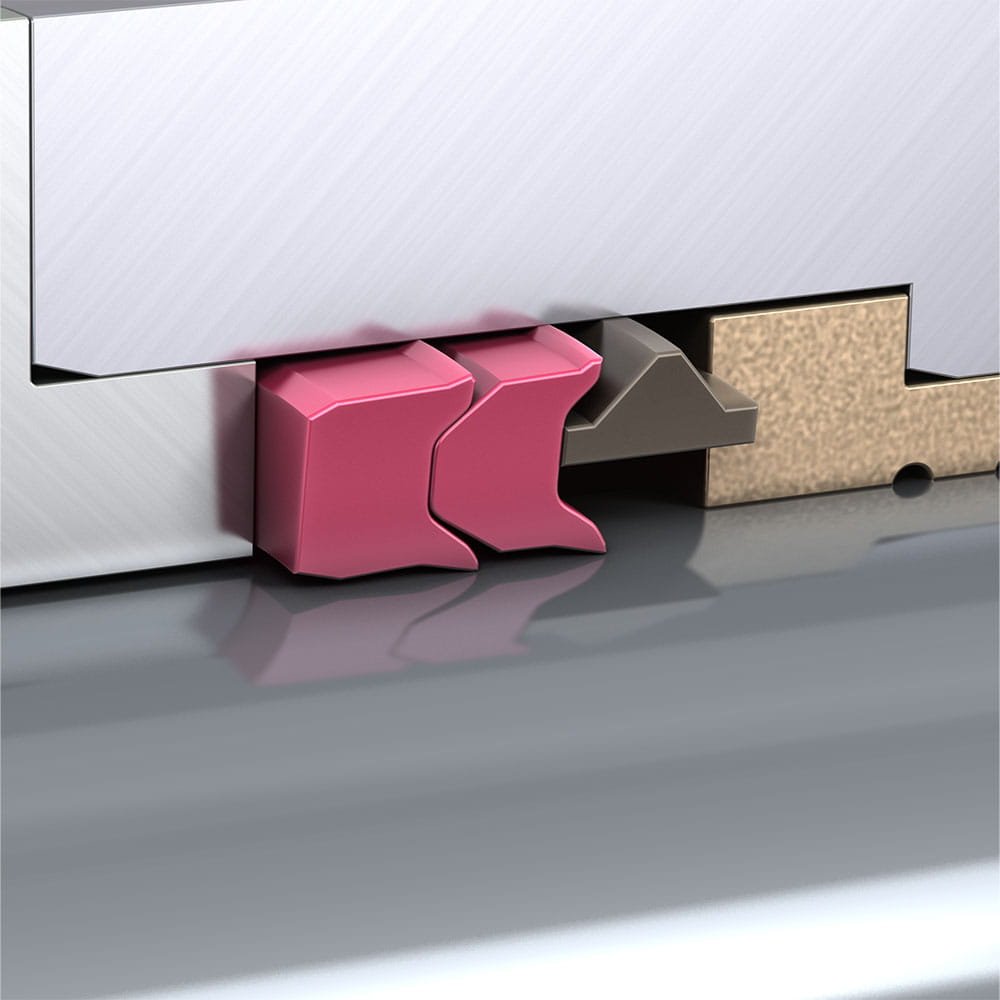

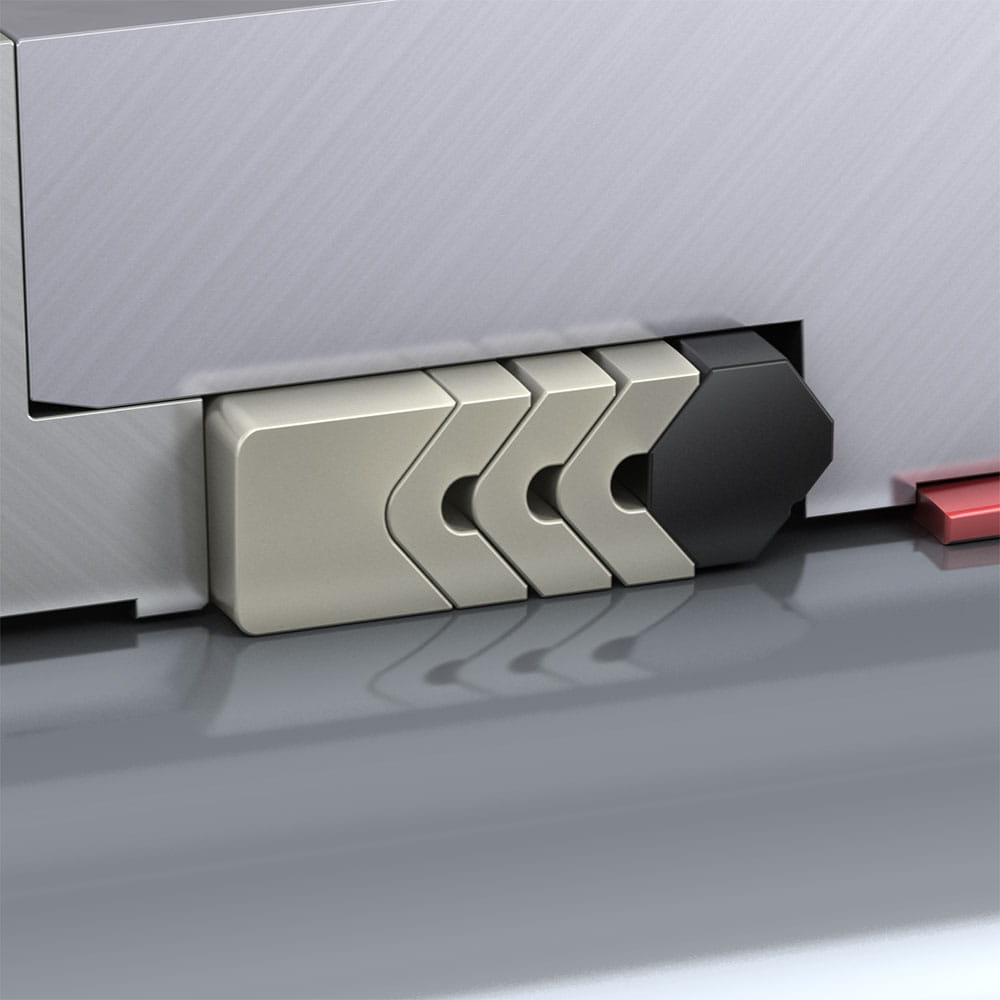

Merkel® Compact Seal VPS40

Multi-part sealing set for piston rods, consisting of a pressure ring, one or two polyurethane V-rings, and a self-adjusting support ring made of elastomer material. The innovative design combines low friction, high functionality, and a universal, installation-friendly construction for all installation spaces – whether as an open ring or in endless form.

-

Reliable sealing performance – even under high side loads and large sealing gaps

-

Versatile application – replaces traditional V-packing sets, even in older installation spaces

-

Extended service life thanks to robust, wear-resistant polyurethane

-

Fast, ready-to-install delivery for diameters from

Ø 80 to 2200 mm, with no tooling costs

Download Product Data Sheet

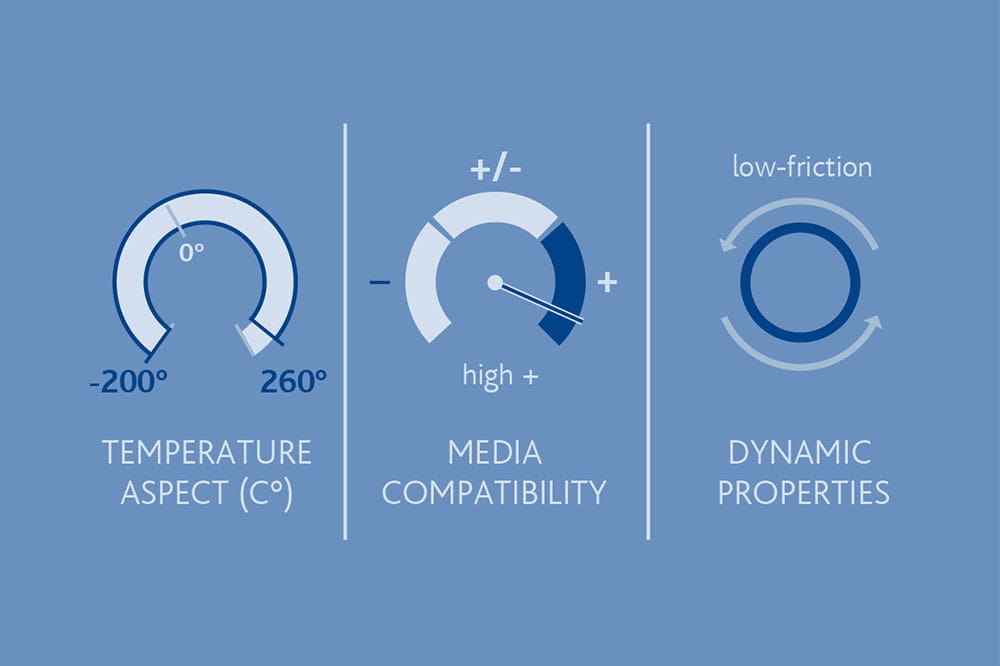

PTFE – Polytetrafluoroethylene

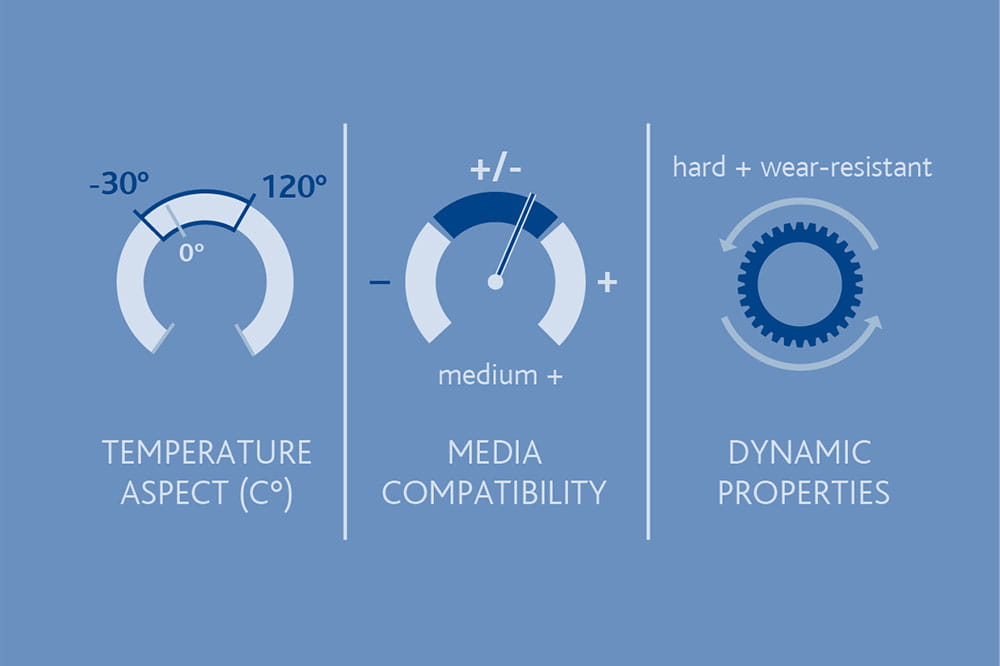

PTFE compounds can be used across a wide temperature range from −200°C to approx. 260°C. When used as a sealing element, the required elastomer preloading component limits the operating range to −30°C to 200°C.

PTFE compounds are hard, barely elastic, and offer very high extrusion resistance. Minimal deformation under compressive or tensile load is almost completely reversible. Their excellent sliding properties – even under poor lubrication – and high chemical resistance make PTFE the ideal material for a wide variety of sealing applications.

Rod seals – our most important designs made of polytetrafluoroethylene

Merkel® Omegat OMS-MR PR

Two-piece compact seal with integrated pressure relief function, designed for single-sided pressure application. When combined with a preloading element made of FKM, it is also suitable for higher operating temperatures. The seal is installed in a housing groove and provides a durable, stick-slip-free sealing solution for dynamic operating conditions.

-

Proven seal ensuring top quality, long service life, and reliable operational safety

-

Reliably prevents pressure build-up in the intermediate space of a sealing system during long strokes, vibrations, or significantly varying extension and retraction speeds

-

Outstanding wear resistance and low friction for uniform, stick-slip-free stroke movements

Download Product Data Sheet

Merkel® Omegat OMS-S PR

Two-piece compact seal for heavy-duty applications with integrated pressure relief function, designed for single-sided pressure loading. The profile ring used as a preloading element is twist-resistant and highly robust, ensuring reliable performance even at higher operating temperatures when combined with an FKM preloading element. The seal is installed in a housing groove and provides a long-lasting solution for demanding hydraulic systems.

-

Proven seal for heavy-duty applications, offering high quality, long service life, and reliable functional safety

-

Effectively prevents pressure build-up in the intermediate space of a sealing system during long strokes, vibrations, or strongly varying extension and retraction speeds

-

Excellent wear resistance and low friction for smooth, stick-slip-free stroke movements

Download Product Data Sheet

PE – Polyethylene

Polyethylene is a versatile thermoplastic material. As UHMWPE (Ultra-High-Molecular-Weight Polyethylene), it is an excellent choice as a sealing material, for example in combination with ceramic counter surfaces. It is extremely resistant to abrasive wear and has a low coefficient of friction, which increases the efficiency and service life of the seal. Universal chemical resistance and FDA compliance make this material attractive for many applications, including in the process industry.

Rod seals – our most important designs made of polyethylene

Merkel® V-packing set DMS0180

The multi-part V-packing set consists of a PE pressure ring, PE V-rings, and an elastomer support ring. It has been specifically designed for use on ceramic surfaces and under harsh operating conditions.

Installation is carried out in axially adjustable or non-adjustable, axially accessible housings with a cover – ideal for demanding industrial applications with high loads.

-

High wear resistance on abrasive counter surfaces ensures long service life

-

Optimized friction behavior for energy-efficient operation

-

High resistance to gap extrusion even under pressure

-

Available as open or endless version for maximum flexibility during installation and maintenance

Download Product Data Sheet

EL – Elastomer

Elastomers (EL) are highly flexible materials characterized by their rubber-like elasticity. They return to their original shape after deformation, making them ideal for use in sealing applications. Due to their chemical structure and cross-linking, elastomers offer good resistance to media, temperature, and mechanical stress. Typical representatives include NBR, EPDM, FKM, and VMQ, which are selected based on the specific application. To increase dimensional stability and pressure resistance, improve tear strength, and reduce deformation under load, elastomers are reinforced with fabric inserts made of cotton or synthetic fibers.

Rod seals – our most important designs made of elastomer

Merkel® V-packing Set ES61

The multi-part sealing set consists of a pressure ring made of PTFE-bronze compound, elastomer-fabric V-rings, and a rubber spring-supported elastomer-fabric support ring.

-

Proven performance under harsh operating conditions and large sealing gaps

-

Bronze pressure ring with high extrusion resistance while improving friction behavior

-

The resilient elastomer backup ring enables installation in non-adjustable housings

-

Available as open or endless version for flexible installation

Download Product Data Sheet

Merkel® V-packing Set ES81

The multi-part sealing set consists of a grooved pressure ring made of polyurethane, elastomer-fabric V-rings, a spring-supported elastomer-fabric backup ring. It has been specifically developed for applications requiring high pressure fluctuations and variable operating conditions, ensuring consistently reliable sealing performance through its robust design.

-

High sealing performance even under pressure peaks thanks to the dimensionally stable PU pressure ring

-

Additional sealing edges on the PU pressure ring prevent air ingress during short-term vacuum conditions

-

Rubber spring elements enable installation in non-adjustable housings

-

Available as open or endless version for maximum flexibility in installation and application

Download Product Data Sheet

Still haven’t found the right product?

Explore many more designs and special configurations in the Freudenberg Sealing Technologies product catalog. Compare designs, materials, and application parameters directly – and find the optimal sealing solution for your application.

View Product Catalog open_in_newRelated Products of the Dichtomatik Brand

Premium Freudenberg brand products meet the highest quality requirements and are suitable for all segments and applications. Complementing this, Dichtomatik brand products are a good solution for moderately demanding, non-safety-critical applications.

Dichtomatik Rod Seals open_in_newHydraulic Selector

Are you searching for sealing solutions for your hydraulic application?

View Hydraulic Selector open_in_new

3D Animations

Discover our innovative sealing solutions for use in Hydraulic Applications

in the new 3D animations!

Related Topics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new