Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

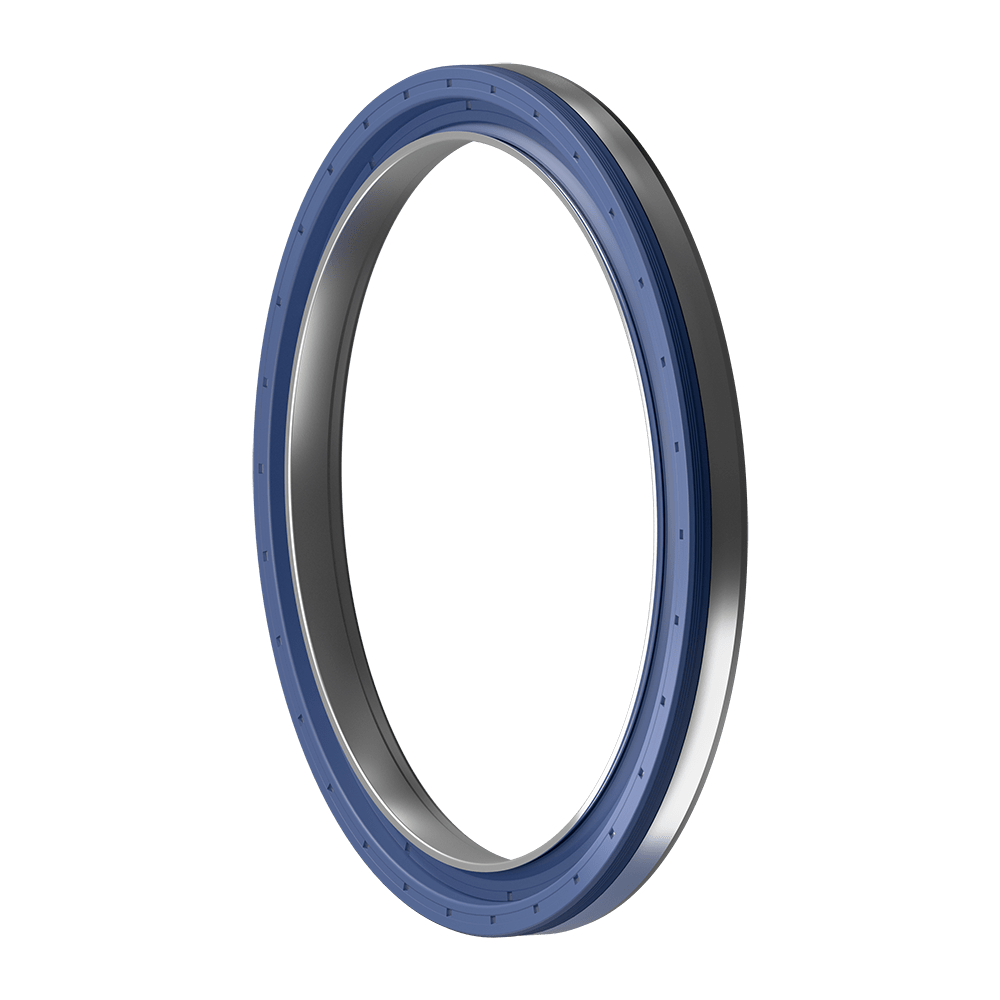

Radial Shaft Seals

Radial Shaft Seals: Precision in Motion

Radial shaft seals (also called oil seals, radial lip seals, or rotary lip seals) are critical components in mechanical systems, designed to prevent lubricant leakage and block contaminants from entering rotating assemblies. At the heart of this technology is the Simmerring® – a trusted name in sealing innovation. Developed through decades of engineering expertise, Simmerring radial shaft seals are used in millions of applications across industries, from gearboxes and pumps to electric motors and industrial machinery.

Each seal features a finely engineered lip that maintains contact with the rotating shaft, supported by a spring-loaded housing that ensures consistent pressure and sealing performance. This design not only protects internal components but also enhances system longevity and efficiency by reducing friction, heat generation, and oil degradation. In short, the right shaft seal choice improves reliability and lowers total cost of ownership.

Our rotary lip seals deliver consistent performance in high-speed and high-temperature environments. As a core type of shaft seal, these radial lip seals – often specified as oil seals in drawings – protect rotating equipment from ingress and lubricant loss.

Material Expertise That Drives Performance

Radial shaft seals are crafted from advanced proprietary materials that provide outstanding thermal resistance, robust wear durability, and minimal friction. Developed through extensive research and rigorous dynamic testing, these materials are designed to ensure compatibility with a wide variety of lubricants, shaft surfaces, and challenging operating conditions.

Whether it’s high-speed rotation, aggressive media, or extreme temperatures, our materials are formulated to meet the demands of modern powertrain and industrial applications. This material science foundation is what enables our radial shaft seals and oil seals to outperform in both standard and customized configurations.

Our oil seal compounds and PTFE-based radial lip seal designs minimize wear at the lip–shaft interface, maintaining stable contact pressure across varying speeds and temperatures.

Find a suitable Simmerring quickly with the Simmerring® Selector.

Radial Shaft Seals – Our Most Important Products Sorted by Application

Services / Added Value

Solutions that combine sealing with additional functionality to enhance system reliability and simplify assembly.

Lube & Seal:

Integrates sealing and lubrication in one unit, improving performance and extending warranty coverage.

Modular Seals and Combi Seals for Industrial Applications

These modular and combination seals offer flexible integration and multi-fluid compatibility for complex industrial systems.

MSS1 (Modular Sealing Solution 1):

Customizable elastomer-metal hybrid seal for modular powertrain configurations.

CASSETTE Seals:

Multi-lip seals with integrated dirt barriers, ideal for commercial vehicles, off-highway and heavy-duty environments.

COMBI Seal:

COMBI is a high-performance seal ideal for off-road axles, combining a duo-lip and polyurethane wiper for enhanced durability and dirt protection during axial movement and rotation.

CASCO® Seal:

Advanced cassette seal with axial lip and metal sleeve, delivering low friction and long service life in diesel and hybrid engines.

CTIS:

CTIS is a robust radial shaft seal designed for central tire inflation systems, enabling reliable pressure regulation in demanding off-road and on-road conditions.

Industrial Applications

These seals are engineered for demanding industrial environments, offering high performance in pressure, temperature, and chemical resistance. Across gearboxes, pumps, and electric motors, these oil seals and shaft seals are selected for reliability in contaminated environments and tolerance to misalignment.

Premium Sine Seal (PSS):

Features a sine wave lip geometry for reduced friction and enhanced sealing stability under dynamic conditions.

Premium Pressure Seal (PPS):

Built for hydraulic and pressurized systems, maintaining integrity under extreme pressure and temperature.

Gerromatic:

PTFE-based seal designed for chemically aggressive environments such as pumps and compressors.

Standard program BAUM:

A reliable and versatile sealing solution for general industrial applications.

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Elevate Your Radial Shaft Sealing Systems with Precision Engineering

Discover precision engineering with Freudenberg Sealing Technologies. Our specialized Simmerring® engineering services go beyond selecting top-tier components. We analyze everything to unlock optimal sealing performance. Trust our expertise and commitment to excellence in sealing systems. Harness precision and innovation for peak performance.

Related Topics

Gearbox Innovations

Dive into this captivating on-demand webinar and explore the revolutionary world of Simmerring® seals.

Watch webinarRelated Products of the Dichtomatik Brand

Premium Freudenberg brand products meet the highest quality requirements and are suitable for all segments and applications. Complementing this, Dichtomatik brand products are a good solution for moderately demanding, non-safety-critical applications.

Dichtomatik Radial Shaft Seals open_in_newRelated Videos

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new