Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

12.09.2017 | Press release

For Secure, Hygienic Connections

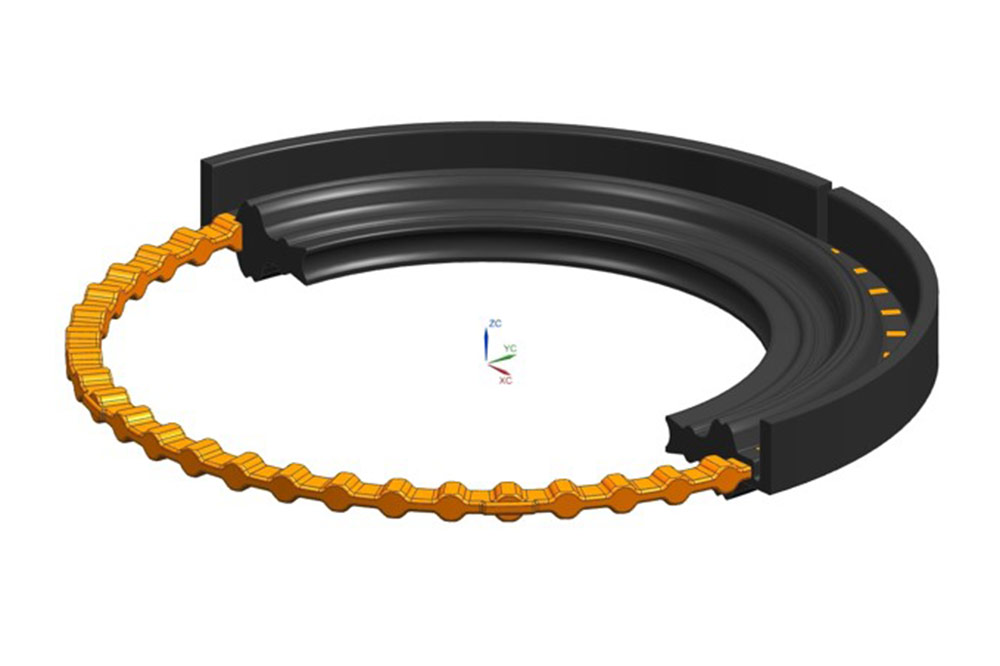

Weinheim (Germany), September 12, 2017. Clamp seals guarantee fast and extremely secure tube connections in machines that are operated continuously. They are especially easy to install and re-separate. At drinktec 2017, Freudenberg Sealing Technologies is presenting its newly developed clamp seals, which not only reliably seal tube connections in production facilities – they also eliminate the costly conversion of connections to a “hygiene flange,” in accordance with DIN 11864. Unwanted over-compression into the interior space is prevented, guaranteeing secure, hygienic tube connections.

Conventional clamp seals have no predefined compression. The result is that a portion of the clamp seal protrudes into the interior of the tube connection when a flange connection is sealed. With the lack of guidelines for tightening torque and depending on the amount of force used during mounting, the sealing element is more or less highly compressed. The part of the seal protruding into the product space not only reduces the internal diameter of the tube. It also prevents complete cleaning, a critical factor in the food and process industries. If part of the seal protrudes into the interior space, difficult-to-clean dead spaces are formed, and bacteria can accumulate there. In the worst case, this leads to product contamination. The flow of media can also lead to seal damage. There is also the danger that protruding parts of the seal could be torn off and enter the product.

The new clamp seal from Freudenberg Sealing Technologies was developed for tube connections in accordance with DIN 32676, ASME BPE or ISO 2852. Its structure has clear differences from those of conventional seals: Thanks to a plastic part incorporated inside it, it has a defined stop, preventing unwanted extrusion into the line’s interior due to the impact of the excessive force. The seal closes almost flush with tube, so the internal diameter of the seal remains precisely the dimension of the tube’s internal diameter. Mounting errors are precluded as a result. The costly conversion of all connections to the “hygiene flange” in accordance with DIN 11864 can be avoided with the use of the clamp seal with stop. An additional binding agent – which is necessary with metal, for instance – is not required with the use of plastic as the stop. When it comes to hygiene, this new development is a major advance: the risk of contamination of an entire product batch is reduced thanks to the flush closure.

Freudenberg Sealing Technologies is presenting these and other innovations, along with its established, tried-and-tested products, for the food and process industries in Hall A3, Stand 239, at drinktec 2017 in Munich (Germany). The company's experts are looking forward to strong attendance at the stand.

Press Release Downloads

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.