Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

03.11.2025 | Press release

Process Engineering: New Extrusion Process For Seal Profiles

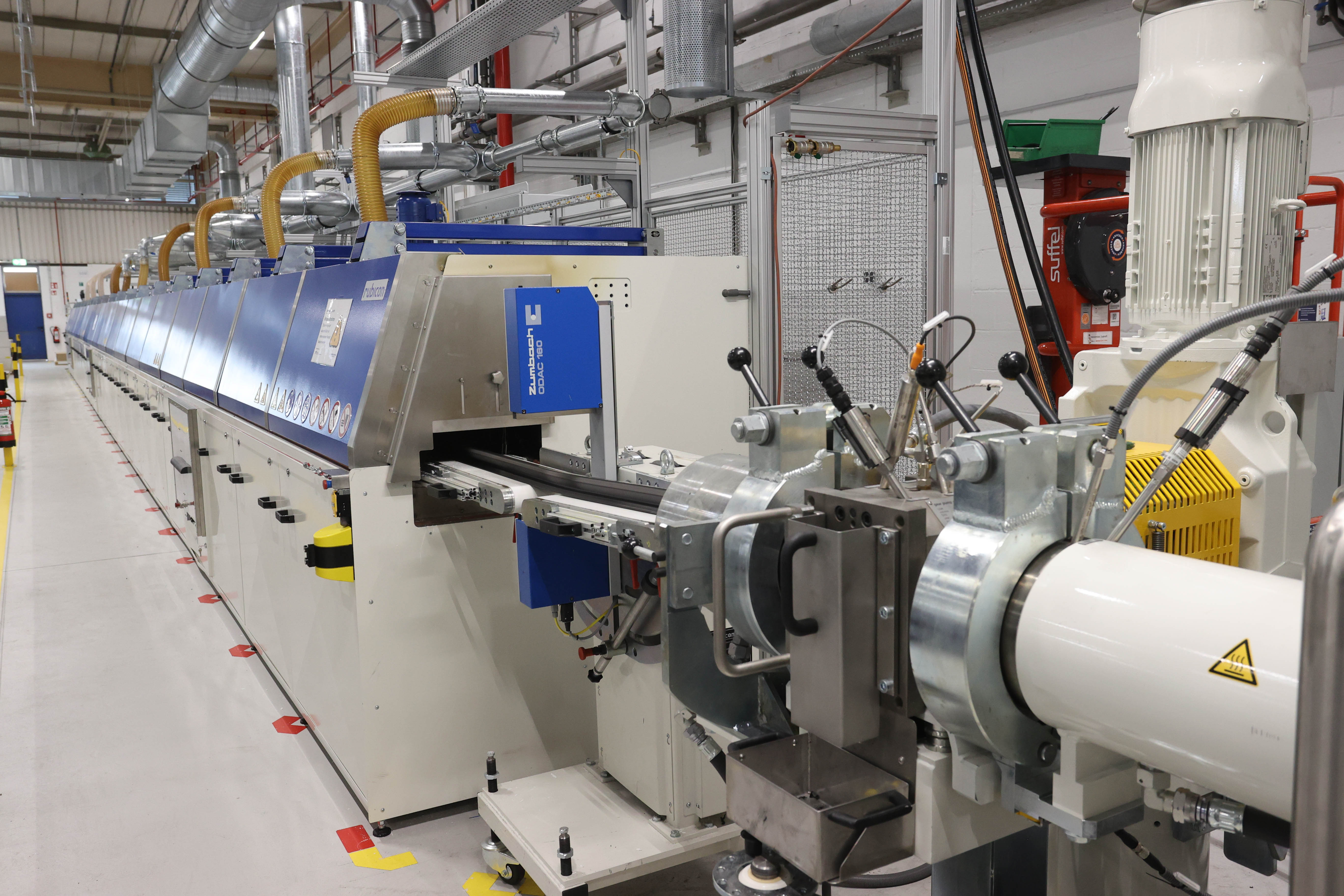

Weinheim, November 3, 2025. The specific properties of vulcanized materials make them essential for many areas of application. In industries such as aerospace, food and beverages and the energy sector, components must meet the highest standards of abrasion and chemical resistance, elasticity, and durability. Delivering top-quality solutions in these areas requires excellent materials expertise, and at Freudenberg Sealing Technologies this goes hand in hand with state-of-the-art production technologies: With LCM (Liquid Curing Method), the company is now commissioning an advanced vulcanizing extrusion line. This is a process in which the fluid used for vulcanization consists of molten salt, heated to around 200 degrees Celsius and filled with vulcanizing salt. The entire line operates in a closed loop, in which the salt is continuously recycled, fed back into the process and reused.

Process stability: Extrusion line vulcanizing with molten salt

The core of the 36-meter extrusion line is a 19-meter salt bath. At the start of the production line, two mobile extruders run on specially installed rails as needed. This allows for a quick conversion of the production environment – from delicate millimeter-scale geometries to large-format sealing cross-sections. The extruded profile is vulcanized in a continuous process in the 200 degree molten salt. The molten salt ensures uniform heat transfer without exposure to oxygen. First, the extruded profile is sprayed with hot liquid salt in a trickling section. This vulcanizes the outer surface of the workpiece and ensures dimensional stability. In the next process step, the profile is fully immersed in the hot salt and drawn through a roller section in the salt bath. Then the profile is gently shaken on a beater section so that the liquid salt falls off. Finally, any remaining salt is removed from the sealing profile along a combined washing, cooling and blow-off section and cooled to room temperature. This manufacturing process enables Freudenberg Sealing Technologies to respond flexibly and quickly to customer-specific requirements in material selection and development.

Special seals. Unique materials expertise meets extrusion technology

The LCM process makes it possible to use a variety of cross-linking systems – including peroxide cross-linking – in a continuous line. Thanks to this high level of flexibility, Freudenberg Sealing Technologies can process a wide range of elastomers. As a result, a wide range of sealing solutions is available for customers’ demanding environmental conditions. High-performance materials from the material groups NBR, EPDM (ethylene propylene diene monomer) and FKM (fluorinated rubber compounds) play an important role in this area. These materials are ideally suited for use in demanding environments due to their outstanding individual properties. Additional material groups are currently under development.

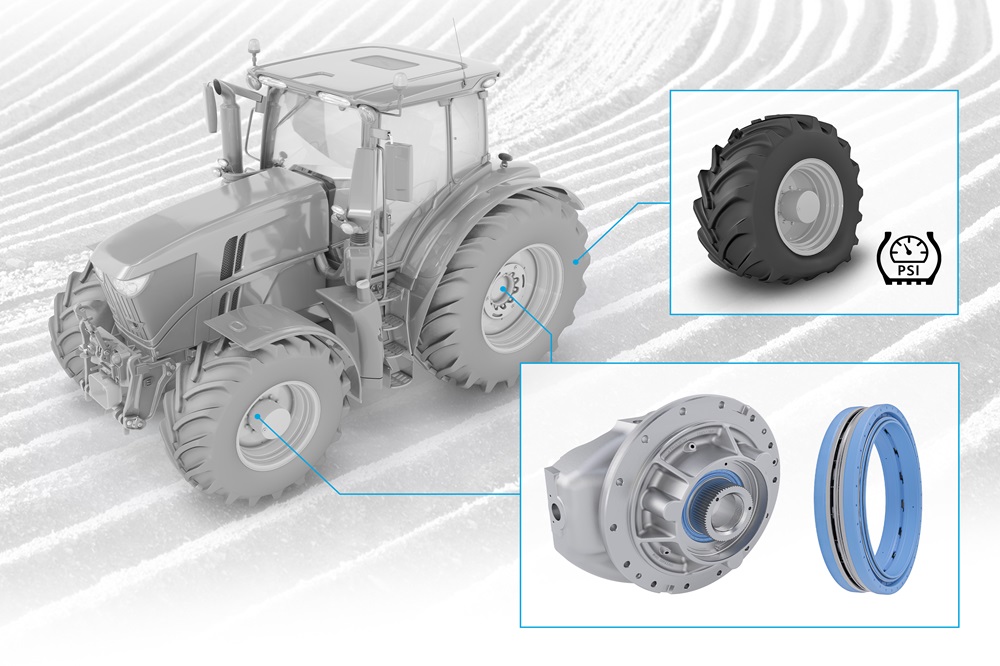

Growth markets: Seals for Power-to-X and industrial applications

Achieving climate neutrality requires high-quality materials along the entire value chain. In onshore and offshore wind farms, there is a trend towards larger turbines with longer rotor blades and taller towers. The loads occurring here are transferred to the structure. This means that the foundation seals must compensate for large gap movements on a long-term basis, even under extreme storm conditions. In such a challenging environment, the expectations for the service life of sealing solutions are enormous: up to 35 years or more. Depending on the requirements and available installation space, Freudenberg Sealing Technologies offers both large-scale seal profiles and already established seal dimensions made with improved materials for wind turbines. The new LCM system expands the options available in both cases.

The energy generated on land and at sea is also used for hydrogen production. Alkaline electrolyzers require special materials and seal sizes that are resistant to the potassium hydroxide solution used in the process. Large seal diameters sometimes have to work with extremely delicate profiles with high tolerance requirements. The process industry also requires large seals capable of withstanding aggressive media and high temperatures. Potential applications range from lids and hoods in soldering systems to hot-air ovens in the food industry. The advantages of molten-salt vulcanization can be fully leveraged in producing such specialized seals. This is because the new LCM process offers access to an extensive materials portfolio, enabling highly precise manufacturing of both small and large cross-sections of seals.

Process monitoring: Integrated continuous measurement process and quality assurance

To enable documented monitoring of the sealing profiles during the vulcanization process, Freudenberg Sealing Technologies has implemented a state-of-the-art sensor system. It measures key product characteristics and is integrated into the production process to monitor the vulcanized seal profiles. In addition, an advanced control system adjusts the process based on the still non-vulcanized profile. Now it is possible to produce filigree profiles with a wall thickness of 1 millimeter with a tolerance of 0.1 millimeters. This is an enormous quality improvement from the previous 0.3-millimeter tolerance range. Thanks to this molten-salt extrusion process, the company’s customers now have access to a similarly wide range of materials that was previously only available through molding processes. It also includes sealing solutions approved in accordance with the regulations of the U.S. Food and Drug Administration (FDA). This is how Freudenberg Sealing Technologies is expanding its range of solutions for large-format seals. Customers benefit particularly from the company’s excellent materials know-how and design expertise.

Josh Barnett

Corporate Communications Manager

Telephone: + 1 734 354 2406

josh.barnett@fnst.com chevron_rightIsolde Grabenauer

Senior Director Communications & PR

Telephone: +49 (0) 6201 960 7467

isolde.grabenauer@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.