Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

24.09.2025 | Press release

Solving Today’s Challenges to Power Tomorrow’s Mobility

Detroit, MI., (USA), September 24, 2025 – Freudenberg Sealing Technologies, a global leader in sealing and mobility solutions, will showcase its latest technologies at the 2025 Battery Show North America, held October 6–9 at Huntington Place in Detroit.

As the mobility industry rapidly evolves, Freudenberg continues to expand its portfolio with high-performance, application-specific solutions that enhance efficiency, reliability, and functionality in both current and next-generation vehicles. At Booth #5208, the company will highlight three key innovations designed to solve industry challenges, including new battery pressure equalization components, advanced sealing for battery systems, and next-level thermal management for high-performance EVs.

Expanded DIAvent® Portfolio

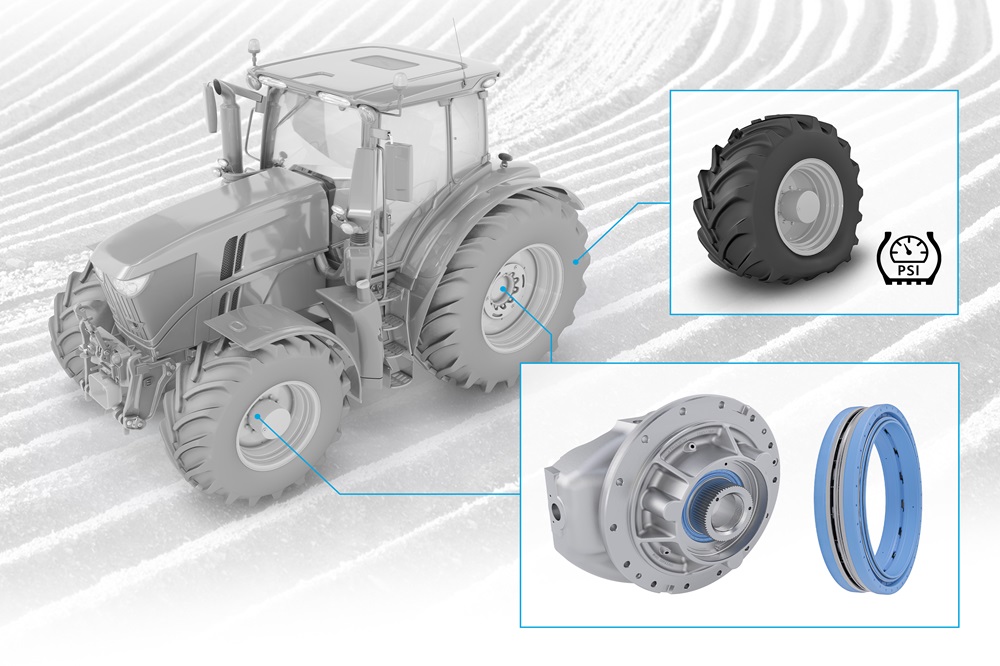

The transition towards electrification brings new challenges to vehicle and equipment design in respect to pressure equalization. Lithium-ion battery housings must remain hermetically sealed for safety and performance yet also require specialized components to regulate internal pressure.

Freudenberg Sealing Technologies has addressed this need with its DIAvent® product portfolio – a patented family of solutions that equalize pressure during normal operation along with emergency degassing functions – tailored for different applications. The current portfolio offers a range of options, from compact, space-saving options for small and mid-sized battery systems, to high-capacity elements designed for larger, high-energy vehicles, as well as solutions for e-motors, axles, inverters and more.

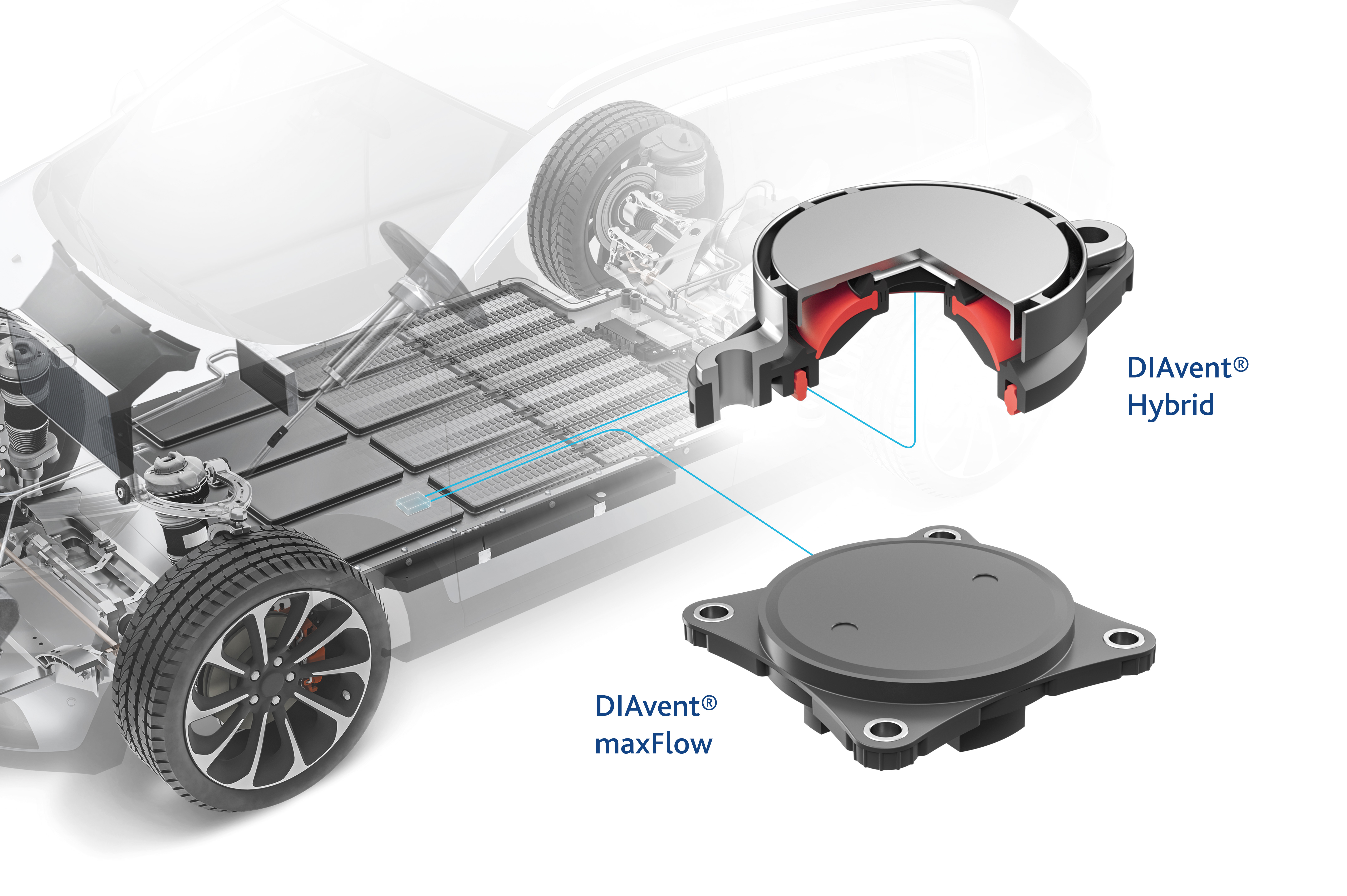

Now, based on customer interest and feedback, Freudenberg has diversified the DIAvent® portfolio further with two new components offering unique features:

- The DIAvent® maxFlow, which features an open degassing vent – rather than one that opens gradually – providing a full degassing rate near the opening pressure threshold and an activation level that can be adjusted between 50 and 200 mbar.

- The DIAvent® Hybrid, which combines permanent bidirectional pressure equalization with emergency degassing, with the added ability to mount the aluminum cover of the vent directly and firmly to the battery housing.

Both new components are suitable for use in high-energy-density battery systems. These additions broaden the DIAvent® scope of solutions, giving automakers and battery manufacturers greater flexibility and tailored functionality across a wide range of operating conditions.

Robust Sealing for Busbar Applications

Busbars, which are essential for energy transfer in battery systems, are notoriously challenging to seal effectively due to their irregular geometries and the harsh conditions they are exposed to, such as aggressive fluids and temperatures. Freudenberg’s groundbreaking media-tight busbar sealing technology, suitable for both rectangular and round busbars, eliminates the need for additional assembly steps, significantly reduces leak risk, and enhances long-term durability. Designed for both low- and high-voltage applications, the solution can withstand temperatures of -40°C up to 200°C, delivering superior resistance to thermal cycling and aggressive media, helping lower total cost of ownership for EV systems.

Fluid Connectors and Solenoid Valves for Battery Thermal Management

As EV batteries grow in capacity and charging speeds accelerate, thermal management becomes increasingly critical. Conventional cooling systems often fall short in ultra-fast charging scenarios. To address this, Freudenberg’s advanced fluid connectors are engineered to accommodate a range of cooling fluids and thermodynamic demands, maintaining optimal cell temperatures and extend battery life. The fluid connectors help to deliver a system-level cost advantage through tolerance compensation, enabling simplified and efficient assembly processes, combining several functions into a single component. Freudenberg’s connectors are tailored for high loads and variable system requirements, bridging the gap between larger batteries and higher performance. Freudenberg’s solenoid valves precisely regulate fluid and air flow in automotive and battery systems by converting electrical signals into controlled mechanical movement.

“Our customers need agile and experienced partners who can rapidly deliver optimized materials and technologies as new challenges emerge,” said Tania Hagel, Global Vice President, OEM Sales, Freudenberg Sealing Technologies. “Our deep expertise in design and materials allows us to deliver tailored solutions that support electric mobility and accelerate the adoption of next-generation propulsion systems.”

Additional Products on Display

At its booth, Freudenberg will also showcase its 3D Waveguide Antenna, a solution that enhances the precision and reliability of radar systems essential for ADAS and autonomous driving, delivering high performance with low signal loss and strong thermal management. Freudenberg offers flexible service models to support customers with this innovation, from full hardware design to consulting and prototyping.

Other products on display include battery cell caps, housing gaskets, a thermal barrier demonstrator and more.

The SurTec Group, a business unit of Freudenberg Chemical Specialties GmbH that develops, manufactures and supplies chemical specialties for surface finishing, and Freudenberg Filtration Technologies, one of the world's leading developers and producers of innovative filtration solutions for customers from a wide range of industries, will also join Freudenberg Sealing Technologies at its booth.

Freudenberg’s presence at the Battery Show underscores its continued commitment to developing high-performance solutions for the mobility space. With its strong customer partnerships, global manufacturing capabilities and dedication to developing products that promote the transition to electromobility in the North American market, the company remains at the forefront of enabling the future of transportation.

For more information, please visit: https://www.fst.com/markets/automotive-truck-bus/electric-vehicle/.

Press Release Downloads

Solving Today’s Challenges to Power Tomorrow’s Mobility

Last update: 24.09.2025

English | DOCX | 90 KB

DownloadDownload Images

Press Release - Freudenberg Sealing Technologies at the 2025 Battery Show North America

Copyright 2024, Freudenberg Sealing Technologies | JPG | 2.74 MB

DownloadJosh Barnett

Corporate Communications Manager

Telephone: + 1 734 354 2406

josh.barnett@fnst.com chevron_rightSilke Herzog

Senior Manager Corporate Communications

Telephone: + 49 (0) 6201 960 6385

silke.herzog@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.