Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

27.05.2021 | Press release

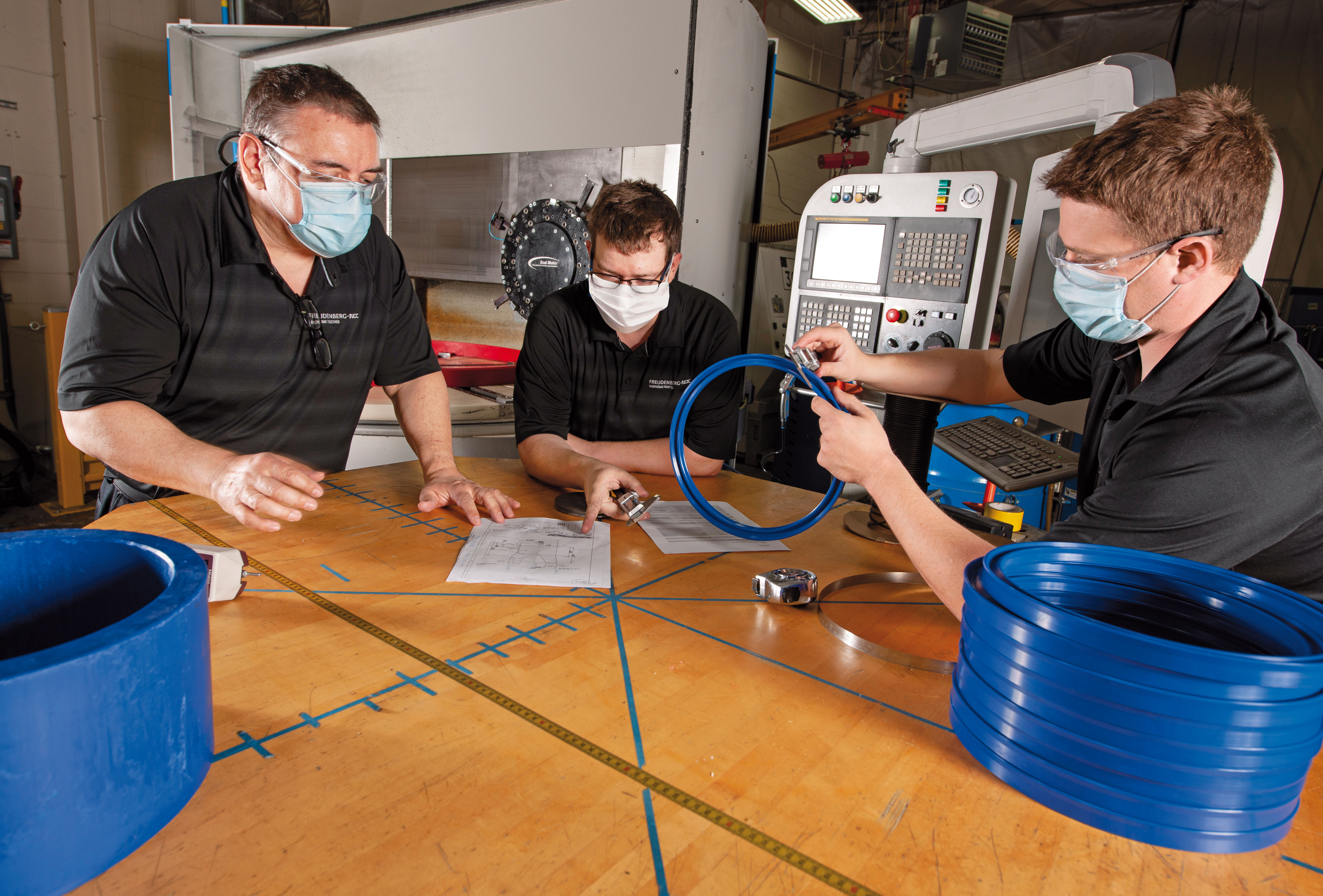

Not Afraid of Extreme Conditions

Plymouth, Mi., (USA), May 27, 2021. The environmental demands placed on the hydraulic systems in large, heavy equipment can be extreme. Pressure, abrasive fluids, extreme temperatures and dirt can all impact the reliability and performance of the seals used to protect their mechanics. Fortunately for manufacturers producing construction, agricultural and mining machinery – among other, heavy-duty industrial applications – Freudenberg Sealing Technologies’ proprietary 94 AU30000 polyurethane provides an outstanding solution – a fact that sealing distributors confirm through increasing sales of this trailblazing material.

The success distributors have witnessed with the seals is attributed to several key benefits. Sealing solutions made from the AU30000 material are not only resistant to water and synthetic hydraulic fluids but can handle major temperature and pressure fluctuations better than any other existing polyurethane on the market. They also offer very high extrusion resistance, allowing them to last longer under more challenging applications than other solutions on the market.

Distributors operating within the Sealing Solutions Group – a group of five companies spread across seven locations in Canada that serves as one of the largest distributors of hydraulic seals, pneumatic seals, shaft seals, self-lubricating bearings and other related components – offer a variety of AU30000 components to their customers and have reported a pattern of consistent performance and increased interest.

“The AU30000 material really outclasses others in terms of friction and pressure resistance and overall mechanical properties,” said Robert Weber, a technical director for Sealing Solutions Group. “And with our machining capabilities, we can create custom parts that our customers require using AU30000 billet supply, resulting in specialized seals and components that feature all the benefits of the material. It’s a standout product that really gives us a competitive edge.”

AU 30000 performance benefits are numerous. Seals and other components made from this bright blue, next generation polyurethane have benchmark capabilities in areas like compression set, tear strength, hydrolysis and extrusion resistance. They can be used to seal systems operating in very hot and cold environments ranging from -40°F (-40°C) to 248°F (120°C). They are resistant to mineral oils, biodegradable hydraulic fluids and water. They also offer a substantially longer service life, saving customers downtime and maintenance costs, especially in fluid-based applications where hot water and steam are present.

In addition to overall performance, seals made from AU 30000 can also reduce the number of needed parts in certain applications, resulting in easier installation and less downtime.

“Any time you can reduce a two-piece configuration to a one-piece without losing any performance, it’s obviously a benefit,” said Weber. “One example is that when using a rod seal made from AU 30000, you no longer need an anti-extrusion ring with it due to its excellent performance under pressure.”

Freudenberg’s culture is driven through the principles of innovation, value and customer service, among other. AU30000 addresses all of these areas, notes John Plut, Sales Director of Fluid Power for Freudenberg Sealing Technologies in the Americas.

“Freudenberg Sealing Technologies is focused on its customers’ success,” Plut said. “By pairing our material knowledge with our extensive understanding of the Hydraulic Cylinder Market, we have been able to develop breakthrough materials like AU 30000.”

“Add to this our extensive partner network across North America, like the Sealing Solutions Group, and you have unobstructed access to this technology, when you need it,” Plut concluded.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.