Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

18.08.2020 | Press release

It Must Be Clean!

Weinheim (Germany), August 18, 2020. Strict hygiene regulations in the food industry present major challenges for sealing technology. Freudenberg Sealing Technologies is enhancing its proven portfolio of hygienic sealing solutions with two products that are also designed for high-pressure applications. This was made possible thanks to special design solutions and the premium elastomer and PTFE materials developed in-house.

Food processing demands strict hygiene and cleanliness standards. It’s also important to ensure that no substances can migrate from the materials coming in contact with food, which could lead to contamination of the product. With its hygienic product line, Freudenberg Sealing Technologies has developed sealing solutions that fulfill food industry standards and are also resistant to CIP/SIP media. The Hygienic Forseal and Hygienic Pressure Seal are the newest members of this innovative product family.

One of the basic requirements for sealing solutions in accordance with the hygienic design standards is a dead-space-free construction. It prevents the collection and settling of product residues and micro-organisms in undercuts, for example. The selection of applied materials and their resistance to hot water, steam, acids, alkalis and high pressures are also relevant. Observing the deformation at the relevant temperature plays a particularly important role in detecting distortions and the associated formation of dead spaces at an early stage in the product development.

Lena Eberspach, Rainer Kreiselmaier and Sina Etter (f.l.t.r.) from Freudenberg Sealing Technologies discuss the new products of the company's hygienic sealing solutions portfolio. Copyright: Freudenberg Sealing Technologies

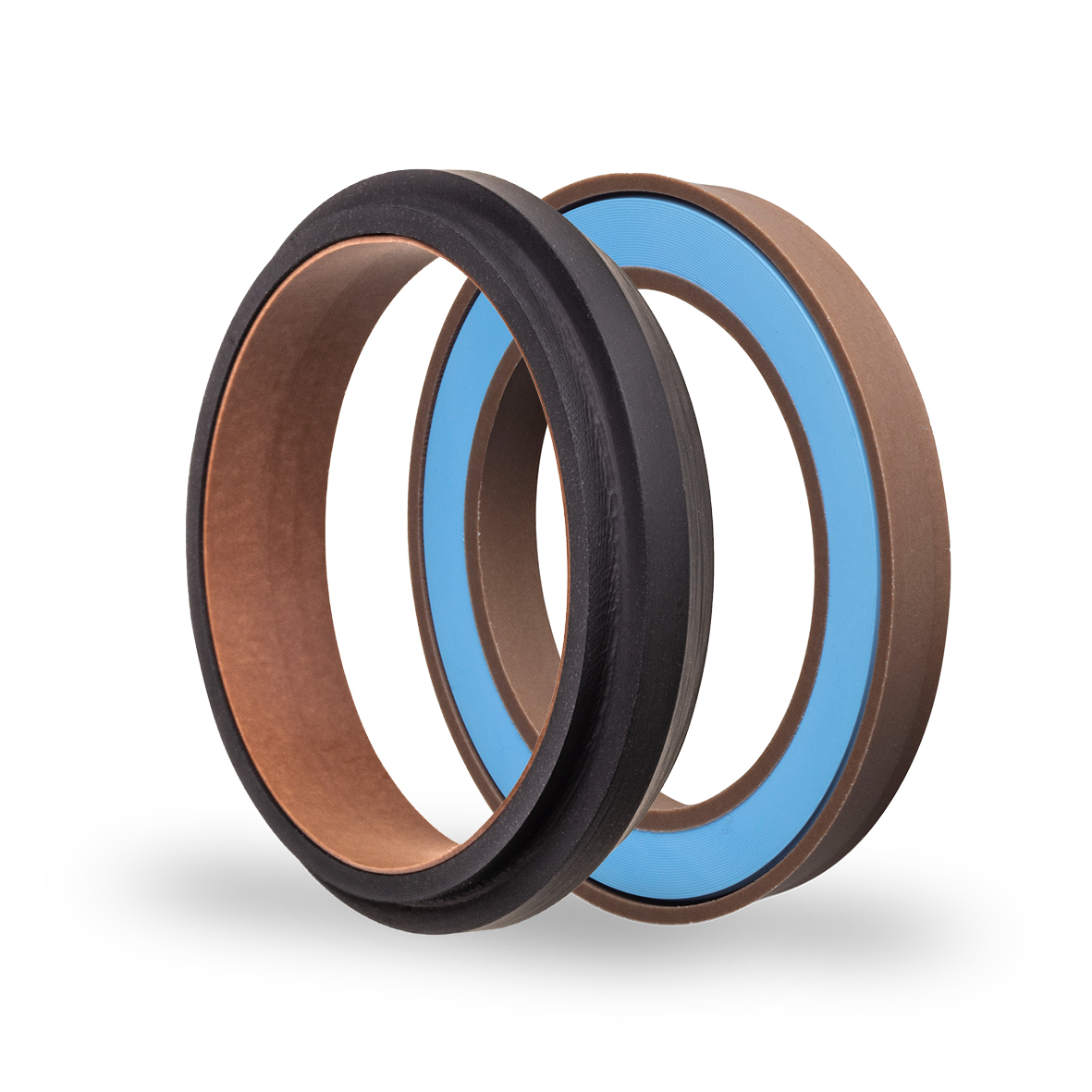

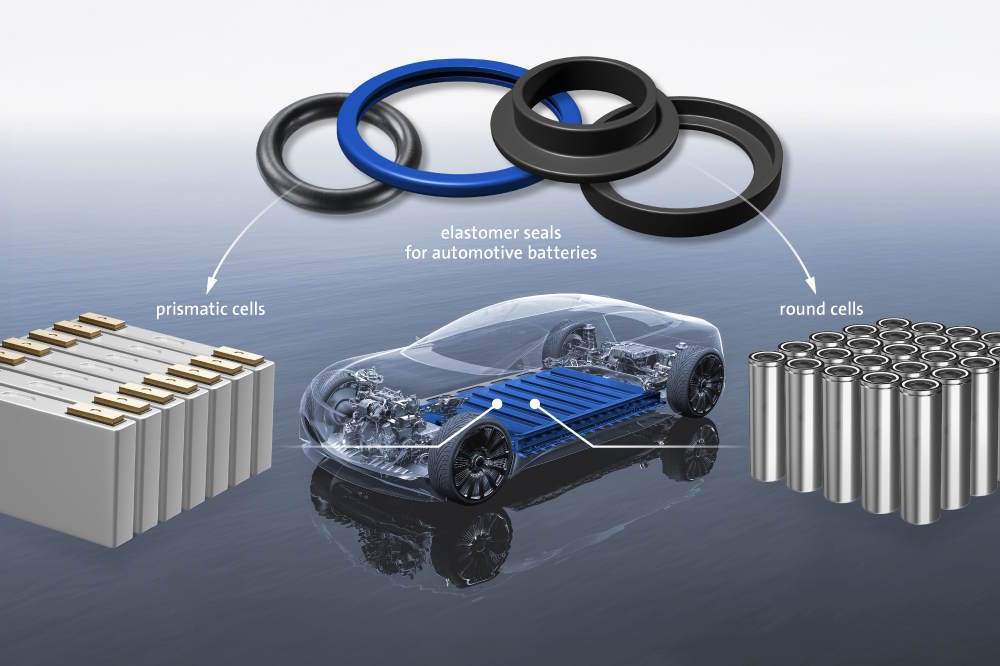

The new Hygienic Pressure Seal from Freudenberg Sealing Technologies was designed specifically for high pressures in food technology, for example as a rod seal for use in valves or pumps. It functionally resembles a traditional rod seal and can meet the same high standards in hygiene, but it performs differently. In addition to sealing at higher pressures, it also features greatly reduced friction, a dead-space-free design and a longer service life. To reduce friction, the Hygienic Pressure Seal uses Quantum® PTFE developed by Freudenberg Sealing Technologies combined with a high-performance elastomer. The rubber ring is designed for long-lasting contact pressure against the PTFE element. Both elements form a planar and dead-space-free surface against the medium. If required, the new Hygienic Pressure Seal is produced in special customer-specific versions, for example with a steel ring for support, as a piston seal with one- or two-sided action or with an additional dust lip.

The second new development, the Hygienic Forseal, is based on the classic and proven Forseal from Freudenberg Sealing Technologies, although its design and materials were adapted to requirements in the food industry. While the classic solution comes with a standard PTFE and a metallic tension spring, this new development uses Quantum® PTFE for its material and an elastomer ring for optimal contact pressure. Additional key features are planar surfaces, certifications conforming to the current food industry regulations and no undercuts. The market response has been consistently positive.

The two new developments enhance the existing and proven portfolio of sealing solutions for hygienic design applications from Freudenberg Sealing Technologies. These also include such products as aseptic O-ring screw connections in accordance with DIN 11864, dead-space-free radial shaft seals of the Radiamatic® HTS II series with an advanced sealing lip made of PTFE and the Hygienic Usit® screw and sealing system for hygienic screw connections.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.