Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

22.05.2018 | Press release

Heat Shields Boost Battery Safety in Electric Vehicles

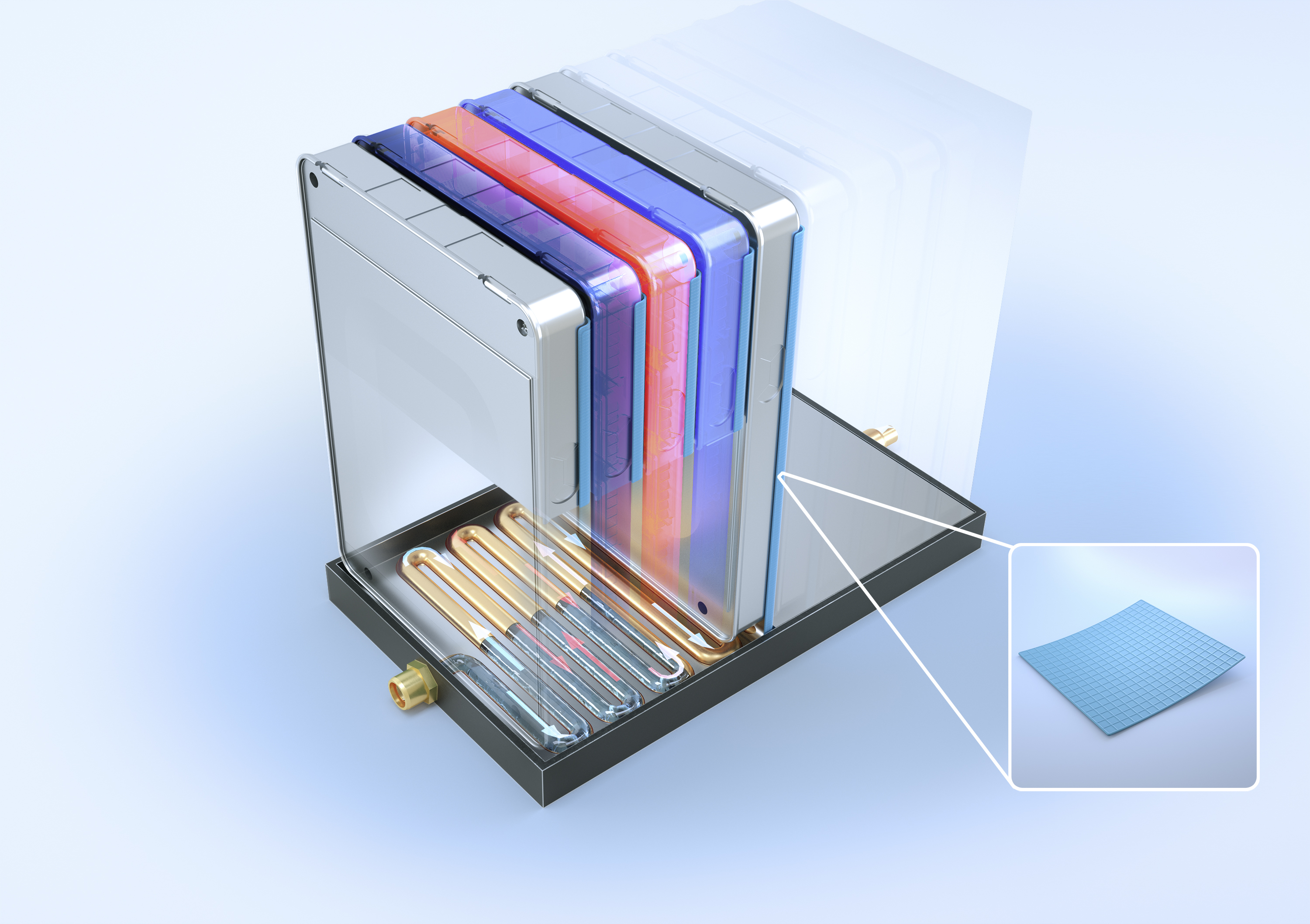

Weinheim (Germany), May 22, 2018 – Due to the growing energy density of battery systems, the developers of lithium ion batteries must satisfy ever higher safety requirements. It is especially crucial to keep a single damaged cell from overheating the entire battery module. Freudenberg Sealing Technologies has developed an innovative heat shield for use in prismatic and pouch cells with almost no impact on the required installation space. It combines the high heat resistance of a silicone-based elastomer with the high insulating properties of air.

The goal is greater range without the battery growing in size and weight: High energy density, which has been battery developers’ top priority, creates a basis for the broad acceptance of electric vehicles. But the more energy is stored in a confined space, the greater the safety requirements. So precautions are essential in case a damaged cell overheats. Experts call the phenomenon “thermal runaway,” and it can cause the temperatures in a cell to rise as high as 600°C. The risk is that the battery’s cooling system would not be able to drain the heat away quickly enough under these conditions. If neighboring healthy cells also heat up due to the heat buildup, a chain reaction can result that, in the worst case, could lead the entire battery system to explode.

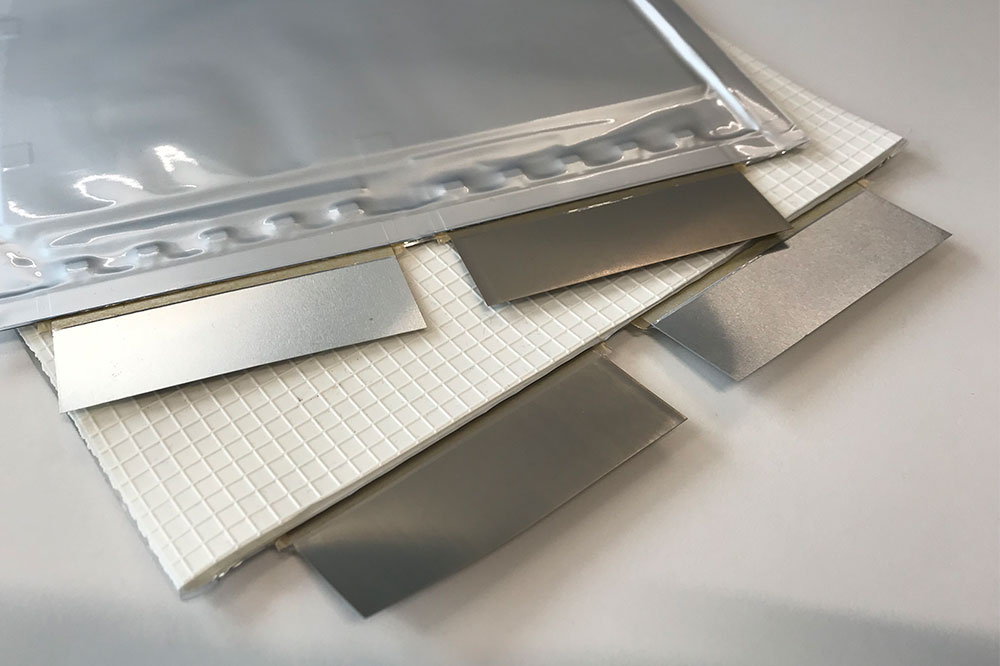

Freudenberg Sealing Technologies is counteracting the risk with a new development. Heat shields between individual cells are designed so that the heat from a damaged cell remains insulated until it can be drained away. The heat shield has three key characteristics: First, the shield itself consists of a heat resistant material, a silicone-based elastomer; second, it slows the heat transfer between the cells with a waffle-like structure – tiny pockets of air provide outstanding heat insulation. Third, the shield is very thin, with a maximum thickness of just 1 mm. The loss of the existing energy density due to the shield’s use is hardly noticeable.

Freudenberg created a new test procedure for the development of its heat shield. It involves mounting samples of the heat shield on a surface heated to 600° C and recording the temperature on its rear side with thermocouples. Series of tests have shown that temperatures significantly under 200°C occur on the rear side after 30 seconds. “This will adequately protect a neighboring cell against the destruction of cathode material or the separator,” said Freudenberg expert Peter Kritzer. “The exact boundary values admittedly depend on a multitude of specific parameters such as the chemistry and geometry of the battery cells.” The way is now clear for the testing of battery modules and systems. Consideration has even been given to the heat shield’s mounting. Since the air pockets adhere well to the smooth metallic surface of a prismatic cell – thanks to a suction effect – an individual shield can be precisely position.

It would even be possible to expand the function of the heat shield with additional development steps. If this flexible formed part were extended over the top of the cell, it could enclose and seal the rupture disc located there. In case of overpressure in the battery cell, the rupture disc ensures that the resulting partially toxic gases escape in a controlled way. “Even more than energy density, safety is the most important characteristic of future battery generations in terms of quality,” Kritzer said. “It can be significantly increased with the help of relatively nondescript components like our heat shields.”

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.