Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

20.03.2018 | Press release

Unique Freudenberg Material Helps Customers Implement Sustainable Solutions

Weinheim (Germany), March 20, 2017 – One of the greatest challenges of the 21st century is the conversion to a resource-conserving, sustainable economy. With this in mind, Freudenberg Sealing Technologies is offering customers its FluoroXprene® family of materials to help contribute to this transformation. Originally developed for use in fuel lines, these materials have the potential for use in new, challenging applications thanks to their outstanding characteristics.

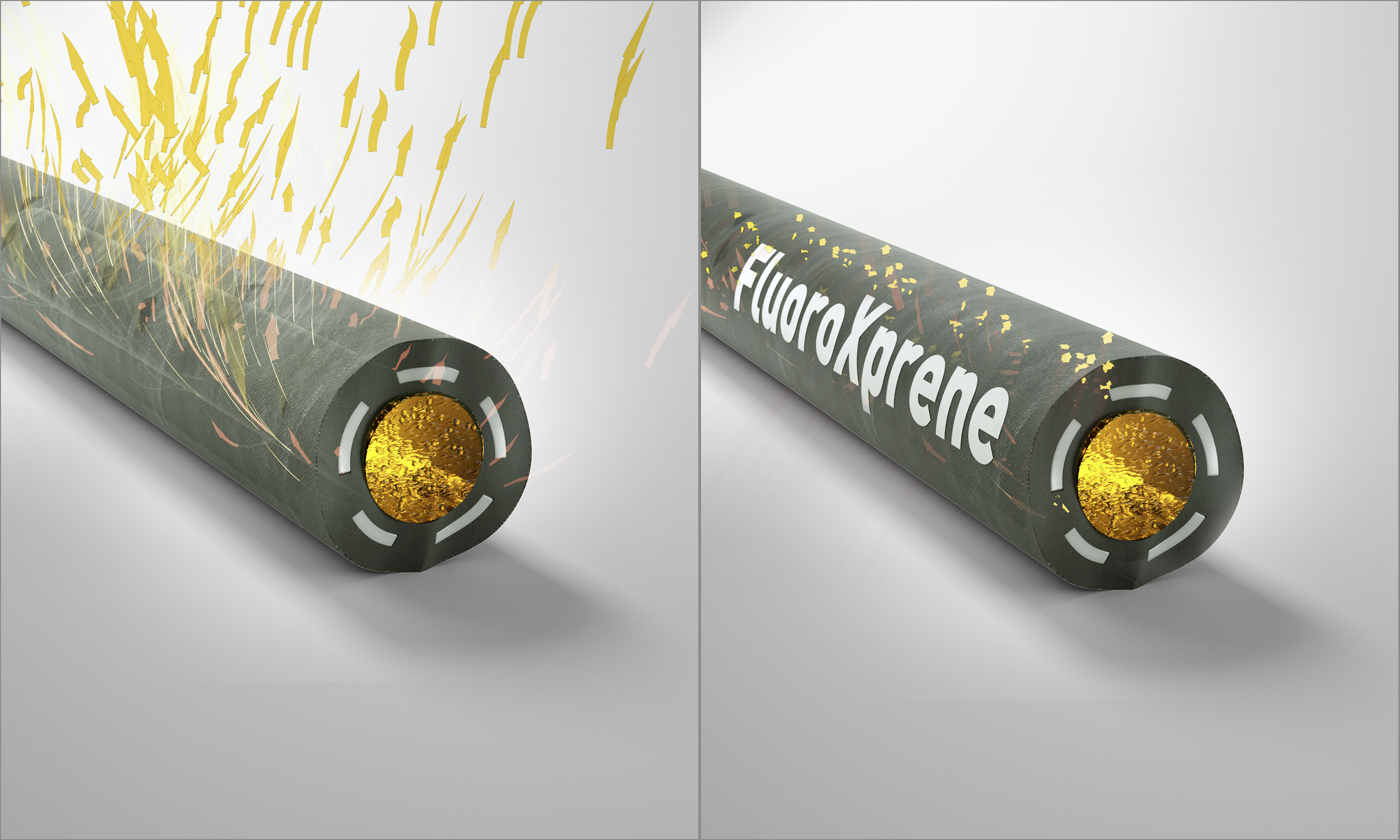

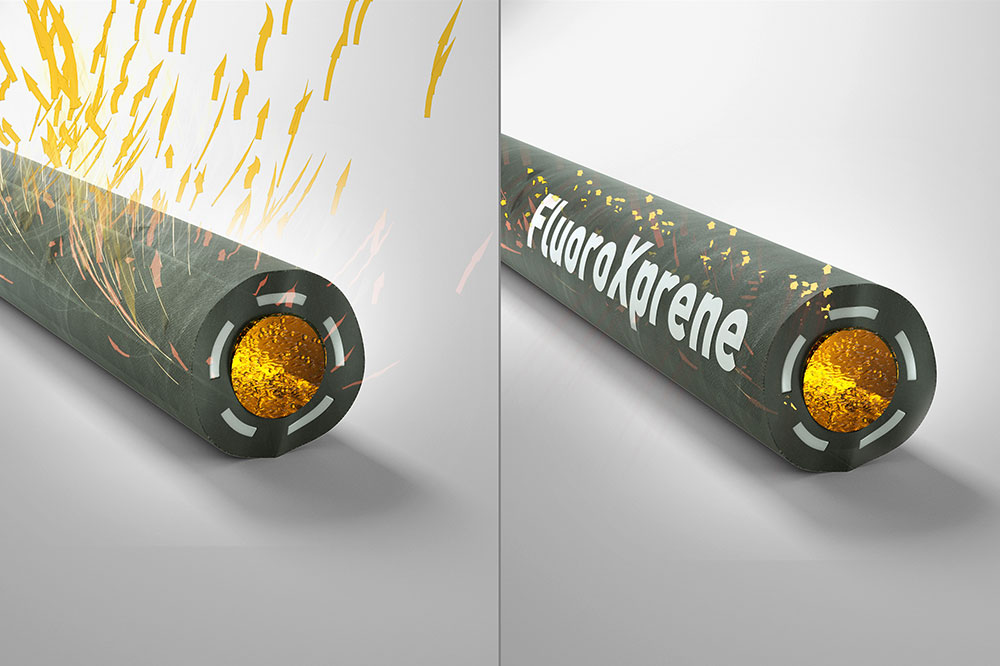

FluoroXprene was developed to reduce the permeation of fuel vapors through the walls of fuel lines. This permeation makes a notable contribution to a vehicle’s hazardous emissions. But it is often overlooked when considering total emissions. FluoroXprene reduces the escape of fuel vapors through the walls of fuel hoses into the atmosphere, slashing them to a fraction of their usual amounts. And this is not just the case for standard fuels – alternative plant-based fuels such as E10 and E85 are also securely contained by FluoroXprene materials.

This grade of FluoroXprene also offers a further safety enhancement in fuel systems. The material is electrically conductive and capable of bleeding off an electrical discharge. This characteristic enhances manufacturer’s ability to protect against a static discharge within the fuel system.

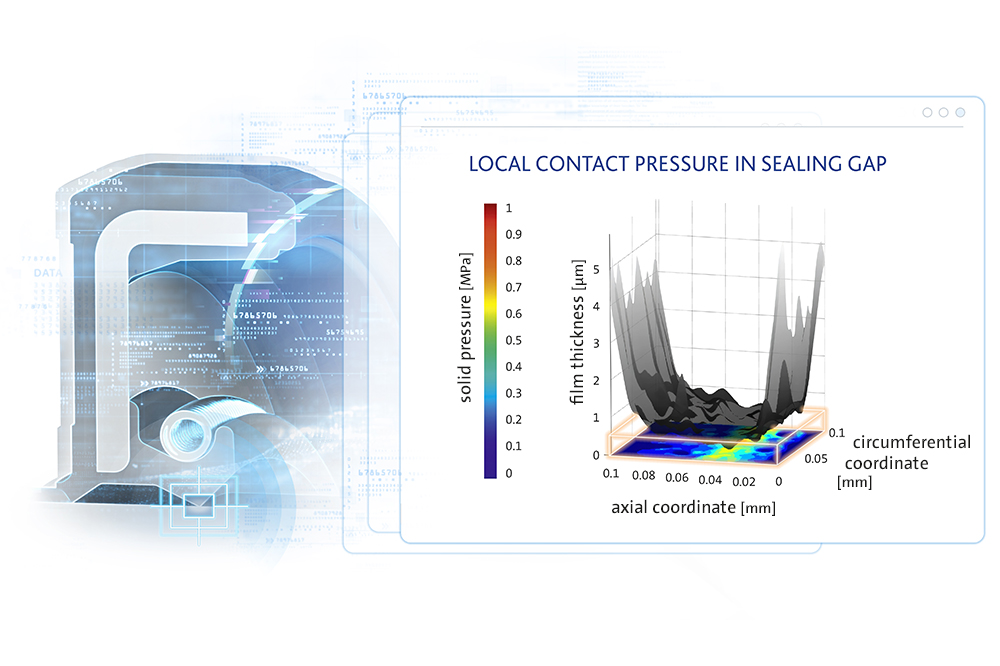

For some time, there have been attempts to use fluoro rubber/thermoplastic elastomer (FKM/TPE) materials in the automotive industry. But with FluoroXprene, Freudenberg’s material experts have succeeded in developing a family of materials made of two highly fluorinated materials that are well suited for processing. The high chemical resistance of FKM is combined with the easy process ability of TPE. The result is a series of materials with outstanding characteristics that have potential use in new applications far beyond fuel lines. By changing the proportions of the two components, product characteristics can be adapted to a wide variety of complex requirement profiles. Thanks to its high process ability, these unique materials can be used in an innovative manufacturing process that reduces Freudenberg Sealing Technologies’ sustainability footprint as well. This process combines proven injection molding technology with a tool design consisting of single cavities. The result: It conserves materials and energy while reducing the production of scrap. FluoroXprene is thus a good example of how companies can conserve resources in their manufacturing operations while increasing sustainability and efficiency on the customer side as well.

More information about the material competencies of Freudenberg Sealing Technologies is available here.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.