Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

13.09.2017 | Press release

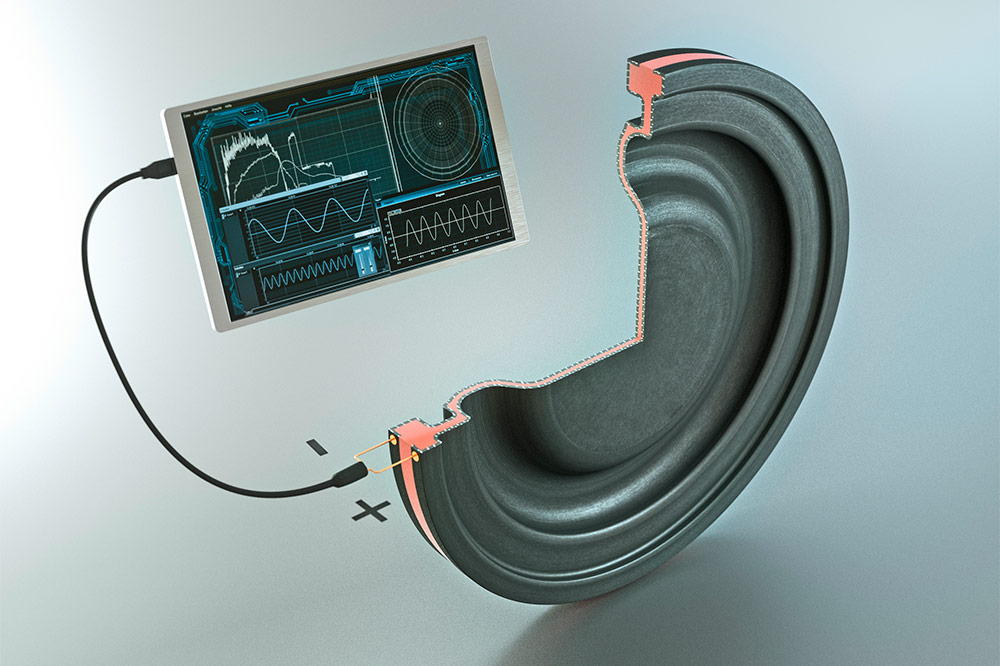

Seals that Monitor Themselves

Weinheim (Germany), September 13, 2017. Seals are increasingly being asked to do more than just seal. In the future, they should be able to forecast when they will break down and perform condition monitoring in real time – all on their own. As a technology specialist, Freudenberg Sealing Technologies is not just anticipating the steadily rising demands on seals but on future sealing materials as well. At drinktec 2017 in Munich (Germany), the company is presenting a new generation of smart seals that is becoming possible for the food and process industries, thanks to a combination of various material characteristics.

Seals primarily consist of materials that cannot process signals in their pure form. That’s why Freudenberg Sealing Technologies’ material developers are investigating materials that seals can employ to become sensors or even actuators, for example, without impairing their original mission.

For instance, special material mixtures come under consideration for this. With a suitable design, it is possible for a seal to indicate its level of wear and for the information to be tied to system data. This makes it possible to predict when a particular seal must be replaced – an important capability for predictive maintenance, one of the core components of Industry 4.0. In this way, operating costs can be optimized: Seals can perform their task over their entire operating life, without being replaced too early. That means maintenance intervals can be scheduled pro-actively on a definite basis. On the other hand, the damage and follow-up costs resulting from leakage – which occurs when a seal is replaced too late – can be avoided.

There are diverse areas of application for smart seals. For now, the study, which is being presented by Freudenberg sealing experts at drinktec 2017, is limited to applications in aqueous media. Investigations are underway on how the study’s results can be carried over to other media.

Freudenberg is exhibiting its study on smart seals and other innovations for the food and process industries at drinktec 2017 in Munich (Germany), in Hall A3, Stand 239. The company’s experts are looking forward to high attendance at their stand.

More information on Freudenberg Sealing Technologies’ products for the food and process industries can be found here.

Press Release Downloads

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.