Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

08.03.2017 | Press release

Freudenberg Offers New Generation of Low-Friction Sealing Solutions to Industrial Transmission Customers

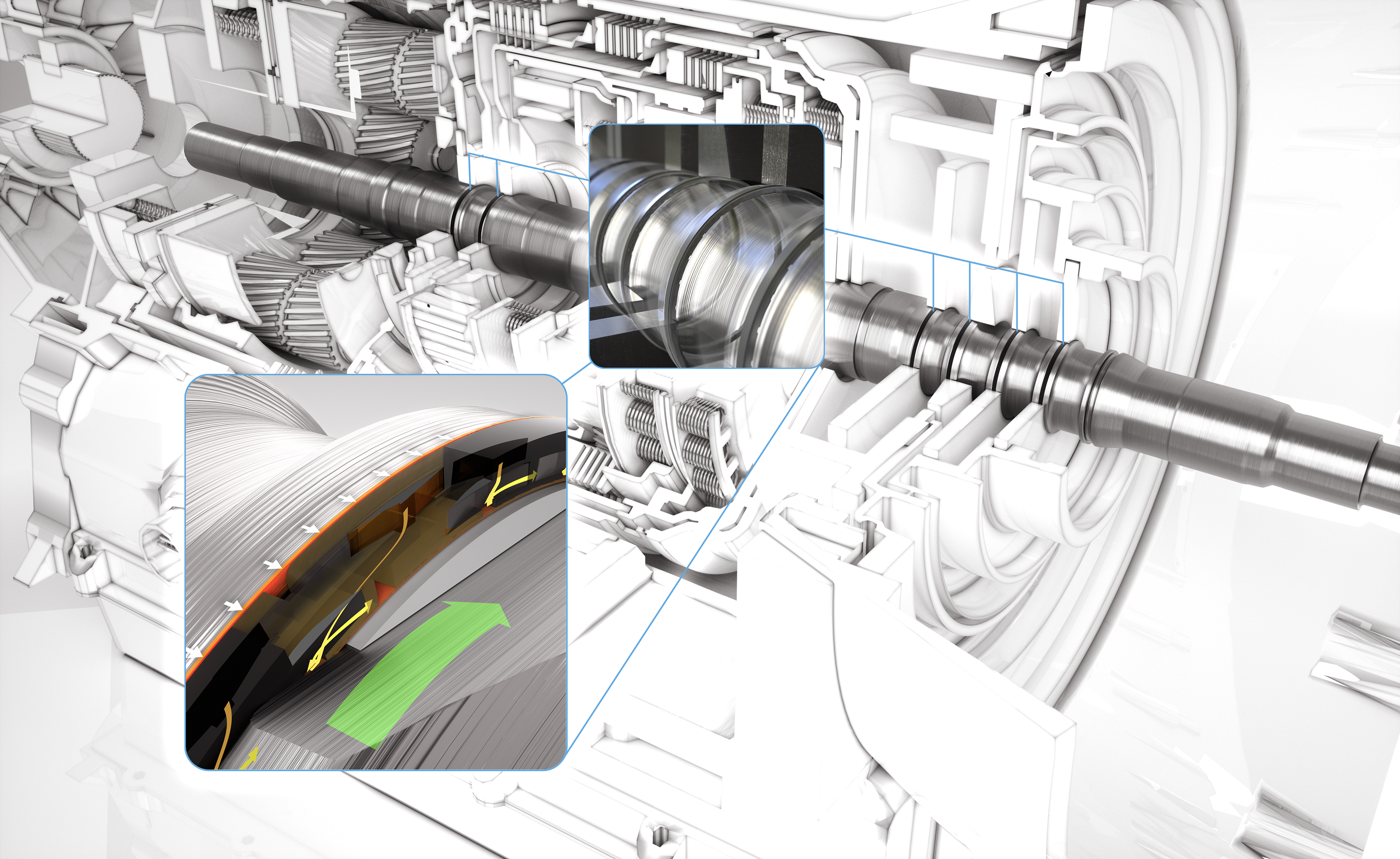

LAS VEGAS, March 8, 2017 – Freudenberg Sealing Technologies is showcasing a new generation of low-friction transmission seals designed to save fuel, lower emissions and extend the operating life of industrial powertrains at the 2017 International Fluid Power Expo in Las Vegas this week. Freudenberg’s Levitas and Levitorq components are part of the company’s Low Emission Sealing Solutions (LESS) product portfolio.

“Mobile machinery and heavy equipment manufacturers are facing the same industrial challenges that automotive manufacturers are facing – stricter environmental regulations, increasing fuel prices and a growing need to keep machinery moving longer between maintenance cycles,” said Joel Johnson, Vice President, Mobile Machinery, Freudenberg-NOK Sealing Technologies. Freudenberg-NOK runs the business operations for Freudenberg Sealing Technologies in the Americas. “Our company has focused its material science capabilities and design expertise on addressing these issues and the result is innovative products like Levitas and Levitorq.”

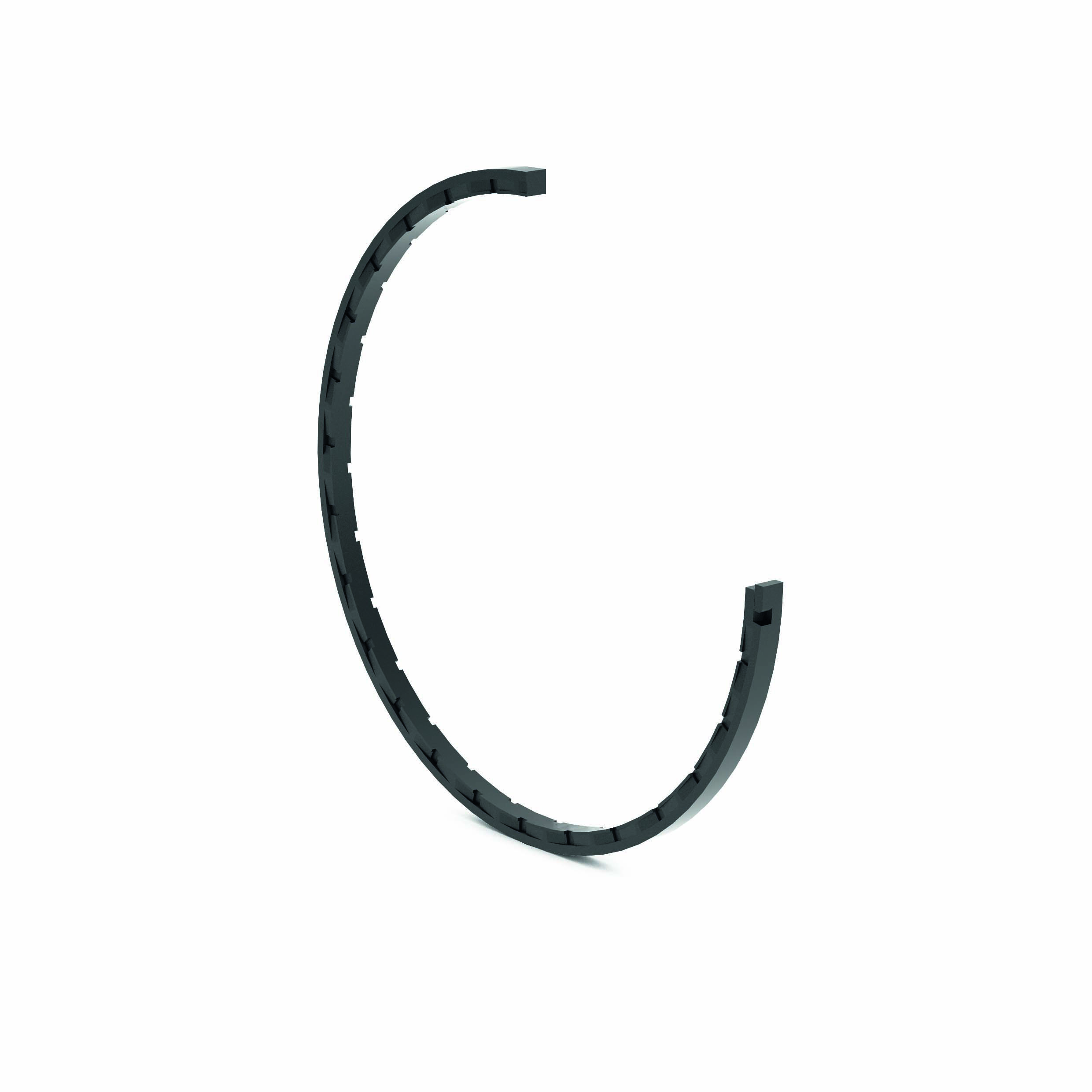

Levitas seal rings are suited for installation in all forms of automated transmissions. A special seal design produces a hydrodynamic oil film between the seal ring and its dynamic counter surface. This reduces friction merely by replacing conventional transmission seals in an automatic transmission. With Levitas, Freudenberg Sealing Technologies is now pursuing a completely new approach: during operation, the seal floats on a hydrodynamic oil film that it generates itself. The film eliminates physical contact between the shaft and the seal ring so that only fluid friction remains and torque levels drop by as much as 70 percent. Since the seal is bi-directional, the effect occurs irrespective of the shaft’s rotational direction. This makes installation easier and more secure for the transmission manufacturer.

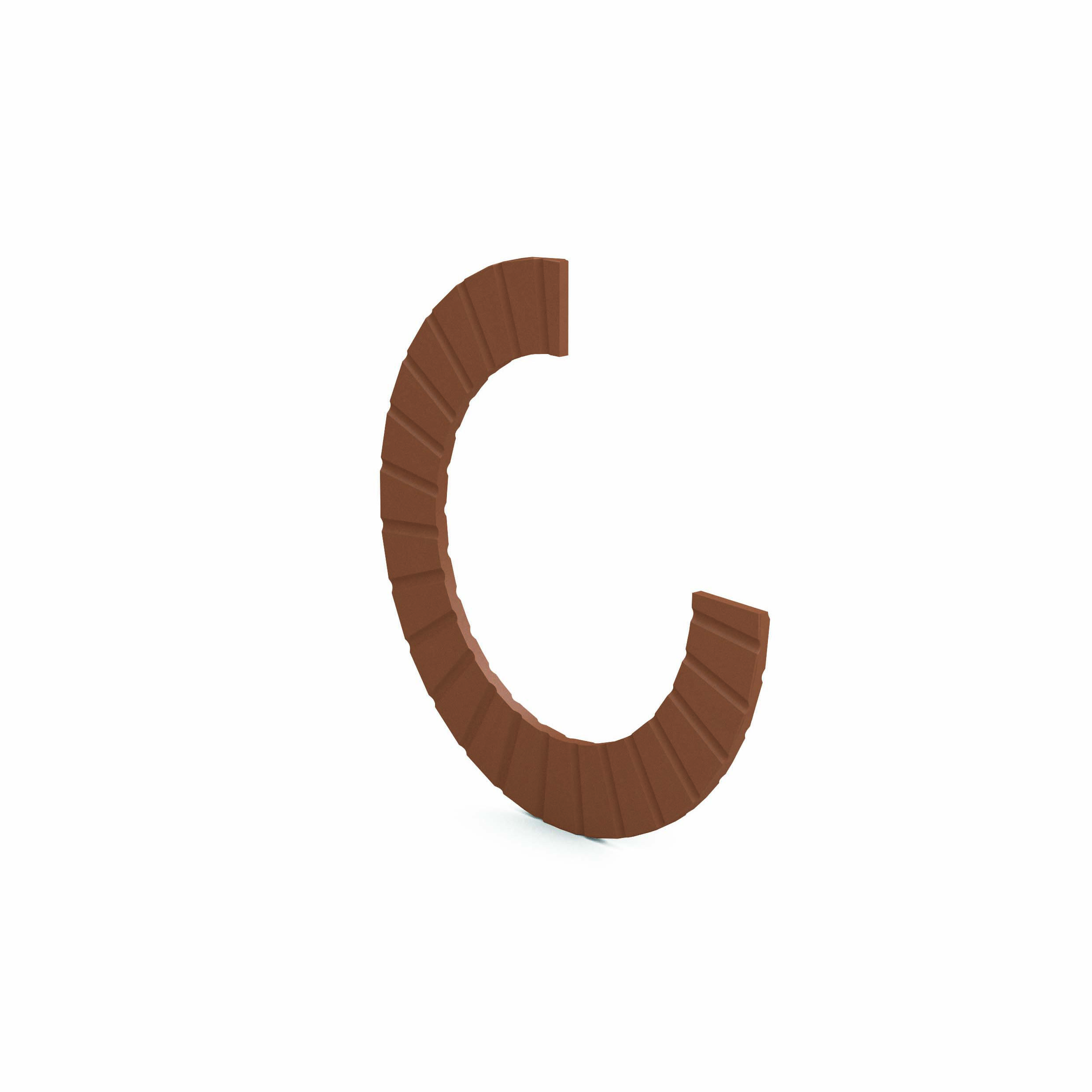

Freudenberg’s Levitorq thrust washer, which also relies on the principles of hydrodynamic oil film technology, is designed to create a surface on which a bearing can roll, or a load can be applied. Traditionally, thrust washers are made from metals, but Freudenberg has used its material expertise and design knowledge, along with proprietary software and testing capabilities, to develop thermoplastic or thermoset alternatives that allow engineers to replace heavy, torque robbing, metal thrust washers. These innovative products help reduce weight, decrease friction, improve thickness/flatness control, and often provide a cost benefit to the customer. The company’s proprietary DTRA (Design Tool for Rotary Application) software can simulate how thrust washer designs will behave in unique applications, thus decreasing development time and cost. The company has further developed thrust washer validation test rigs that can be outfitted for dry and lubricated testing.

Freudenberg’s LESS portfolio of engine, transmission and e-mobility products include a variety of seals, gaskets, encoders, accumulators, sealing modules and lightweight housings. These products have been uniquely engineered to reduce friction and weight, cut fuel consumption, ease installation challenges and lower emissions. First developed and benchmarked for automotive applications, Freudenberg has been able to leverage its LESS technology for other industrial applications resulting in a significantly shortened development cycle.

“Our company’s ability to leverage innovation across product platforms and industries is truly unique and insures that all of our customers benefit from state-of-the-art technology solutions,” Johnson noted. “We invite IFPE show visitors to stop by our booth and see the possibilities for themselves.”

In addition to a complete range of sealing components and accumulator products, Freudenberg Sealing Technologies will also conduct daily technical presentations at its booth, S82630, in the South Hall 3 of the Las Vegas Convention Center. For more information about Freudenberg at the IFPE, please visit https://twitter.com/Freudenberg_FST or http://ifpe.fst.com. For more information about LESS, please visit http://less.fst.com.

Press Release Downloads

Freudenberg Offers New Generation of Low-Friction Sealing Solutions to Industrial Transmission Customers

Last update: 08.03.2017

English | PDF | 79 KB

DownloadNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.