Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

09.05.2017 | Press release

Freudenberg’s Advanced Testing and Materials Address Flavor Transfer Challenges

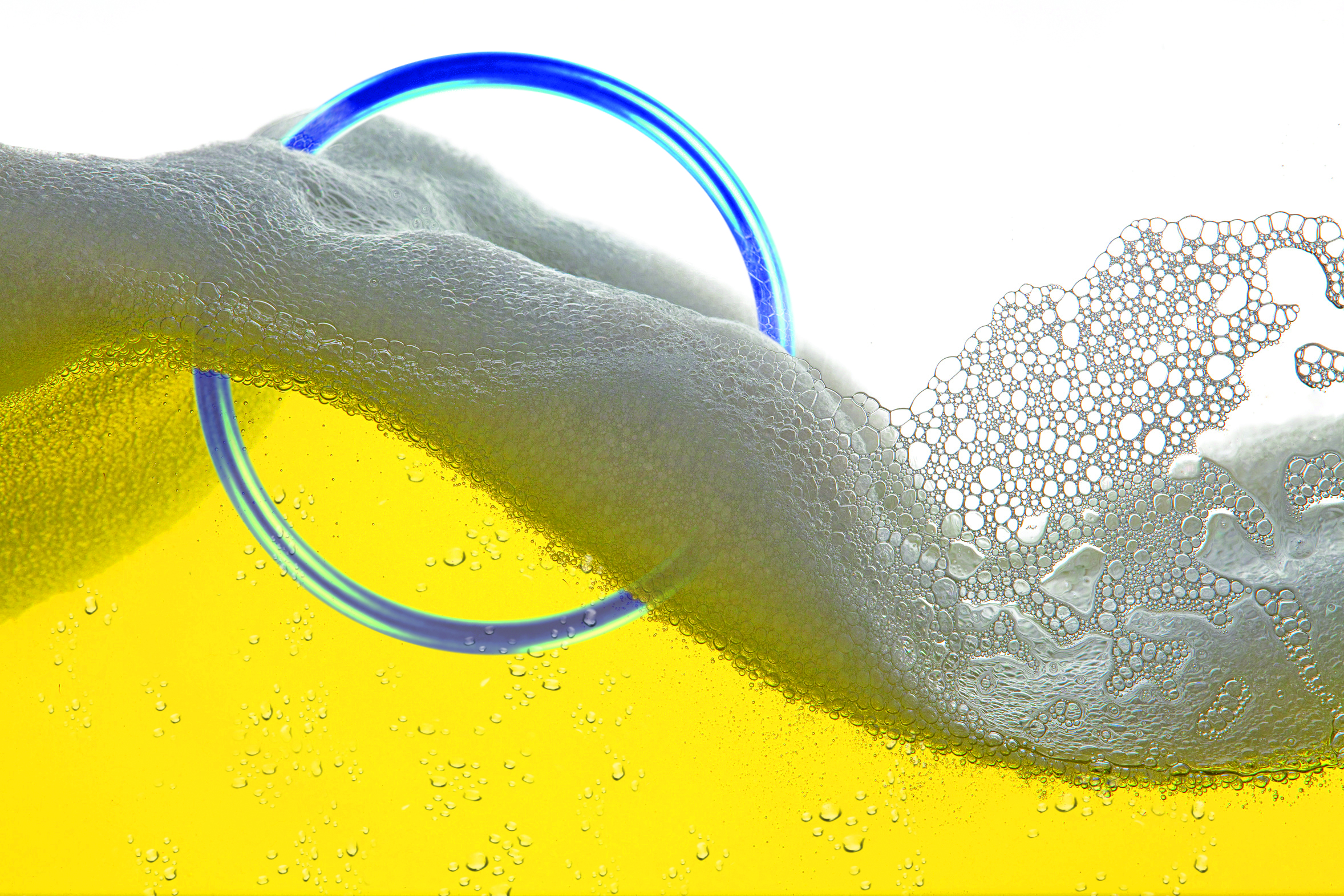

TAMPA, Fla., May 9, 2017. As the beverage preferences of customers shift toward more flavored waters, teas, energy drinks and coffees, equipment manufacturers are faced with tough, new sealing challenges. Today’s drink dispensers play host to dozens of syrup and drink combinations that increase the complexity of industry issues like flavor transfer, use of multiple cleaning solutions and system leaks. Now, more than ever, advanced materials and robust product testing are required to meet industry performance expectations.

Freudenberg understands that meeting a material specification does not guarantee a component’s success – especially in the complex world of consumer libations. The company offers customers a variety of globally-certified sealing materials and testing capabilities to analyze and resolve beverage equipment challenges. Those materials and testing capabilities, which include Compressive-Stress-Relaxation (CSR), flavor transfer/retention, state of cure, and analytical testing, set the company apart from competitors and help guarantee that its seals and components achieve their intended function the first time and every time.

“To protect against flavor transfer, it is important to understand a variety of complex factors, including the material science of different elastomer types, the selection and development of the rubber compound, and the various test methods used to measure fluid and temperature compatibility with this compound,” said David Clark, Central Laboratory Operations Manager, Freudenberg-NOK Sealing Technologies. “When you account for these criteria in your testing, you develop a robust material that will perform well in whatever you decide to expose it to.” Freudenberg-NOK Sealing Technologies runs the business operations for Freudenberg Sealing Technologies in the Americas.

Clark will address these criteria in detail during his presentation at the International Society of Beverage Technologists (ISBT) annual meeting, BevTech 2017, on May 10 at 10:15 a.m. In addition to this presentation, Freudenberg-NOK will showcase a trio of globally-certified sealing materials, including its 70FKM727 low-temperature Fluorocarbon (FKM) material, its Fluoroprene XP family of highly fluorinated premium materials and its 70 EPDM 291 material.

Freudenberg’s 70FKM727 low-temperature Fluorocarbon (FKM) material is NSF51 and EC1935/2004 compliant. 70FKM727 dramatically improves low temperature flexibility over conventional FKM materials at working temperatures of at or below 0˚ C (32˚ F). The material is highly resistant to low and high ratio syrups, municipal water treated with chloramine or chlorine and cleaning solutions.

The Fluoroprene XP family of highly fluorinated universal premium materials is approved for use in Europe and the United States and can be used by the food and beverage industry in the most demanding sealing situations. The Fluoroprene XP portfolio consists of five materials that are available in two hardness grades. The appropriate compound is chosen based on the area of application and the need to bond to metal or fabric.

The company’s 70 EPDM 291 material offers impressive mechanical properties that change comparatively little after contact with cleaning agents. The material demonstrates very good stability in acids, bases, polar solvents and Clean In Place / Sterilization In Place (CIP/SIP) media. It is stable in water and steam to 180 °C (356 °F) and has very good resistance to aging, ozone and light. Like Fluoroprene XP, 70 EPDM 291 complies with European and American FDA food contact regulations.

More information about Freudenberg’s sealing products for the food and beverage industry is available here.

ISBT holds its annual meeting, BevTech, each spring to provide a forum for presentation of scientific and technical papers and for meetings of the technical committees. For more information: www.bevtech.org/bevtech-2017

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.