Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

19.09.2017 | Press release

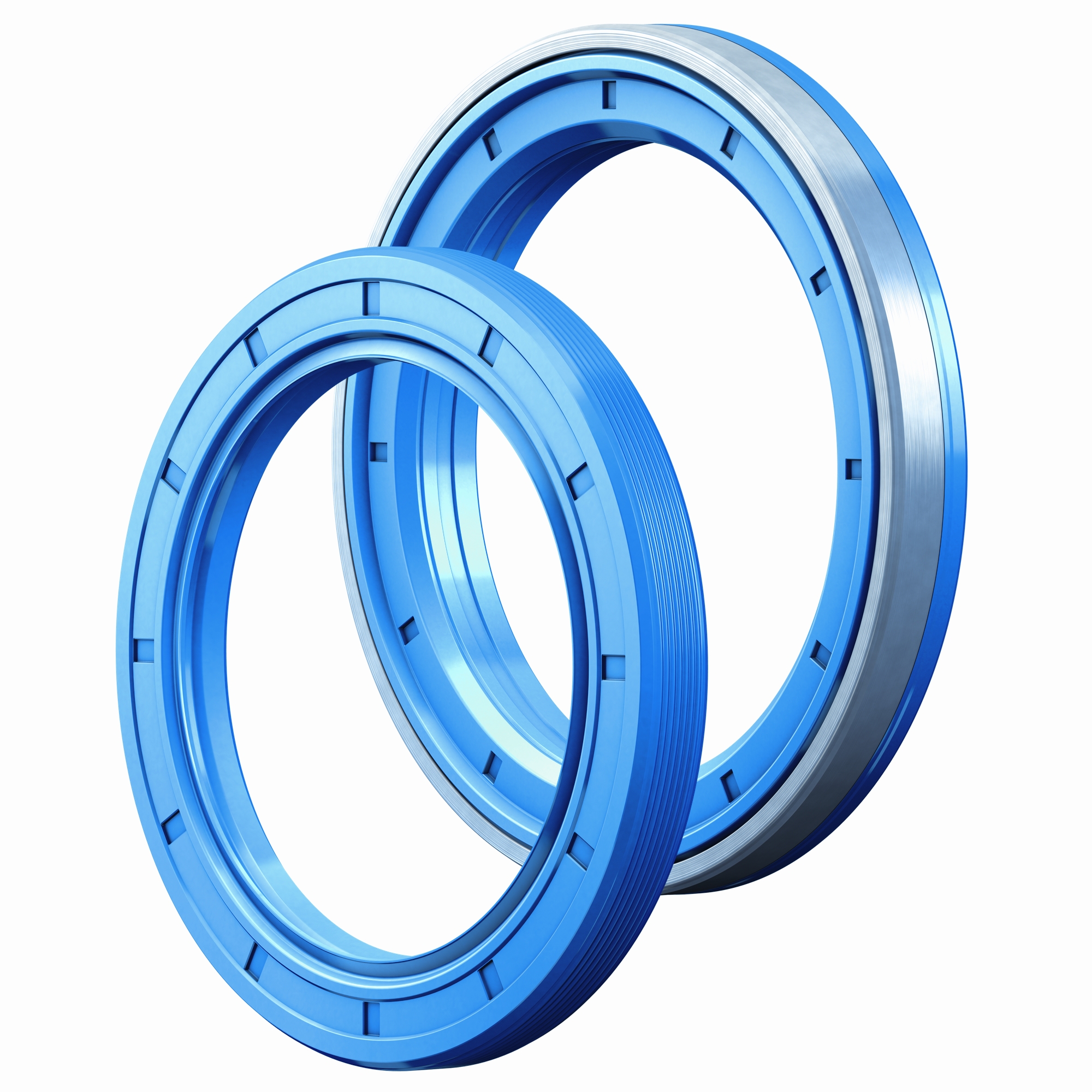

85 Years of the Simmerring® – A Success Story

Weinheim (Germany), September 19, 2017 – Small, nondescript and ostensibly unspectacular – it is often developments of this exact description that lead to groundbreaking innovations in the world of technology. The idea of manufacturing seal sleeves from leather scraps became the starting point in one of the most important developments in sealing technology: the Simmerring®. For 85 years, the Simmerring® has been inseparable from the Freudenberg history of success, and, in Europe, its name has even become a synonym for (radial) shaft seal rings of every kind. Today the Simmerring® is a high-tech product whose key functions go far beyond the sealing of the shaft against its housing.

It all started with the economic crisis of 1929, which plunged the leather industry and thus the Freudenberg tannery – which was founded in 1849 – into difficulties. To better distribute its risks in the future, Freudenberg began to diversify the company and serve a broader market. A sample of a leather sleeve from the United States was the inspiration for giving Walther Simmer and his team the job of developing a machine that could be used to produce lip seals made of leather scraps.

The first Simmerring® emerged in 1932. Consisting of a leather sleeve firmly built into a sheet metal housing, it immediately surpassed the preceding technology. Additional steps in its development, such as incorporating a worm spring and the impregnation of the leather with Acronal, brought valuable improvements in functionality. Freudenberg gradually solved the initial problems, such as low resistance to high temperatures and solvents. With the continued development of the Simmerring®, Freudenberg became the world’s leading sealing specialist. In 1953 – 21 years after its ancestors first emerged – Simmerring® production reached the 100-million mark.

Equipped with a sleeve made of PTFE, chemically resistant and suitable for use in a temperature range of -40°C to 260°C, the Simmerring® conquered the internal combustion engine in Europe and America in 1980. The next major step in its development provided even more performance characteristics far beyond its actual sealing functions. In 1997, Freudenberg developed a Simmerring® with a multipole encoder. By interacting with sensors, it provides information about its position, from which precise data about rotational speeds and angles can be acquired – values of key importance to today’s assistance systems and engine management. The Simmerring® with condition monitoring provides information about its own condition. The technology also makes the replacement of Simmerrings solely on the basis of maintenance schedules unnecessary. They also offer functional security in hybrid and electric vehicles thanks to their conductive nonwovens, which prevent the dangerous buildup of electrostatic charges between housings and shafts.

The Simmerring® has shown that it can be high-performing even in its tiniest form. In 2010, Freudenberg succeeded in developing and manufacturing the smallest elastomer Simmerring® to that point. In micro-versions of pumps, drives and actuators, it reliably seals shafts just 1 mm in diameter. It is insensitive to geometric tolerances and functions without difficulty at more than 10,000 rpm.

The Success Story Continues

Despite other success, Freudenberg laid the foundation of its success in the sealing field 85 years ago with the development of the Simmerring®. Along with countless modifications, steady, ongoing development with an eye to efficiency, environmental protection and sustainability has led to breakthroughs in sealing technology and new, additional functions again and again. Nowadays, the right Simmerring®® is available for nearly every conceivable application. No end to its development is in sight either. Freudenberg will develop suitable Simmerrings for coming requirements as well.

More information on the 85-year history of the Simmerring® can be found here open_in_new

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.