Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

08.05.2017 | Press release

Freudenberg Highlights Industry-Tested Steel Radial Shaft Seal at 2017 AISTech

After passing a three-year field trial with flying colors, Freudenberg Sealing Technologies will showcase its Merkel® Radiamatic RPM 41 radial shaft seal for the steel industry at the 2017 AISTech Conference and Exposition – the steel industry’s premier technology event – at the Music City Center in Nashville, Tenn., May 8 to 11.

Tested by 35 steel mills across North America and Europe, the seal is designed to address the needs of work roll bearings, working to keep lubricant in and to keep water out, helping to protect the costly bearings.

“This radial shaft seal is such an affordable workhorse and performs perfectly as intended to protect expensive rolling bearings without being over-engineered,” said Marc Liepins, sales director, Freudenberg. “The seal allows for near-effortless installation and is readily available for us to supply. We received positive feedback from our customer trials with this product.”

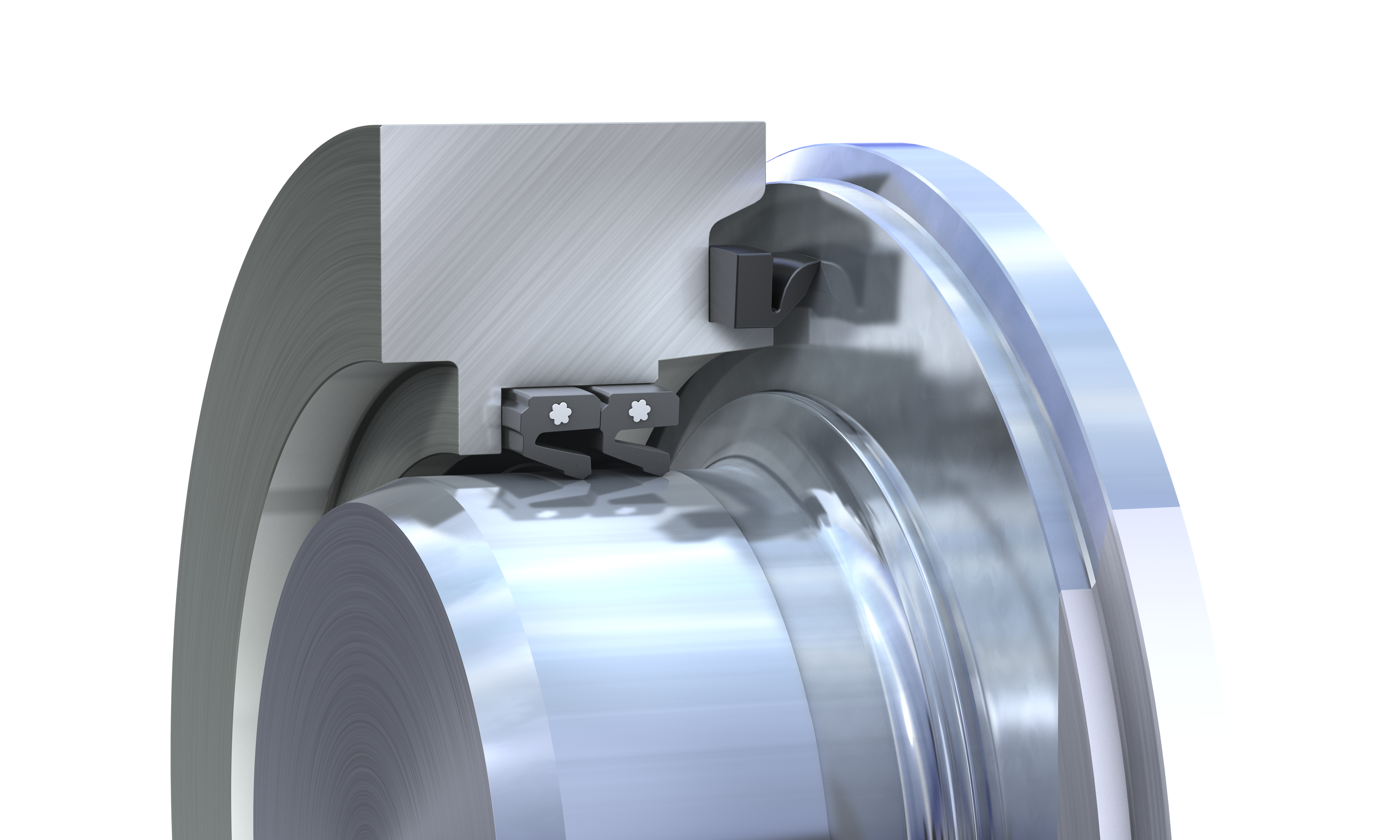

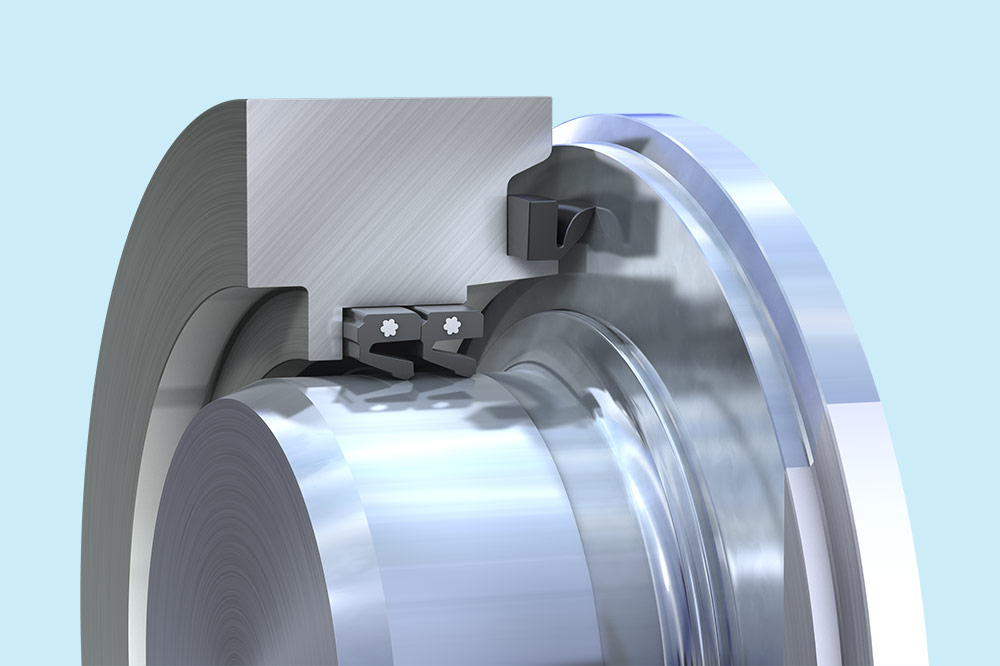

With an average durable service life of 2,000 – 4,000 operating hours, the Merkel® Radiamatic RPM 41 seal is completely covered in rubber and fits in open or cover-plated housings, leaving no trace in the installation space and allowing it to be easily slid into place. It also functions without a spring element at the sealing lip. These features help to eliminate potential hazards that other metal objects can inflict on roller bearings.

The seal also comes with the Merkel® Enviromatic water guard to offer superior protection against water and dirt ingress. The Merkel® Enviromatic is unique in that it features a defined, linear sealing edge instead of a soft, flat sealing lip. The functional, linear contact allows the guard to remain intact even in cases of axial shaft misalignment, resulting in maximum protection.

The seals are offered along with Freudenberg’s complete service package, which includes first time installation assistance on-site, troubleshooting support and replacement seals that are shipped to the customer within 24 hours.

In addition to the Merkel® Radiamatic RPM 41 and Enviromatic water guard, Freudenberg will showcase a variety of other industry-focused sealing products at its AISTech booth, including a high performance trio for HAGC cylinders: Merkel® Omegat seals designed to help extend lifetime functionality, Merkel® Guivex guide elements for high surface loads and Merkel® PTFE wipers for improved protection of the sealing system. Robust sealing concepts like modernized V-packings for forging presses and steam hammers round up the portfolio

Attendees of the AISTech Conference who would like more information can visit Freudenberg’s booth (#1643) at the show or visit rpm41.fst.com.

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.