Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

23.01.2023 | Story

VinFast: E-Cars Made in Vietnam

Southeast Asia is a region with great potential for e-mobility. The young Vietnamese company VinFast is making giant strides and already offers a broad range of electric vehicles.

VinFast was formed just five years ago. What was the environment like when it was launched?

It was full of opportunities and challenges. The vision of an independent automotive industry with a global value chain had been powerful for decades. Many nations had clearly enjoyed its benefits. But there was no automotive industry of that stature in the country until recently. A number of companies were active here, but they imported and assembled vehicles with a low localization rate, and their production costs were higher than those in Southeast Asian countries like Thailand and Malaysia. Supporting industries were rudimentary. It was not an easy environment.

Le Thi Thu Thuy

Le Thi Thu Thuy, known as Madame Thuy Le, is the CEO of VinFast and Vice-Chairwoman of its parent company Vingroup. She was born in the Binh Dinh province of Vietnam and graduated from the Foreign Trade University in Hanoi. She obtained her MBA at the International University of Japan and also completed a chartered financial analyst (CFA) program. She joined Vingroup in 2008. In 2017, she assumed responsibility for opening the first auto factory in Vietnam.

How did VinFast get started?

The potential of the Vietnamese auto market is considered one of the highest in the world. About five years ago, the car ownership rate was only 23 cars per 1,000 people and has only grown marginally since then. This has opened up a huge opportunity to shape the country’s mobility. Vingroup accepted the challenge. The decision was made to start from scratch and introduce a new vehicle brand with the right products. The result was VinFast.

What were the most important steps taken in the recent years?

It has been a time for speed. VinFast was formed in 2017 and entered the market with its first vehicles in 2018: They were e-scooters and cars still powered by internal combustion engines. E-cars followed in 2021. In January 2022, we became one of the world’s first auto companies to completely switch to all-electric drive. Only five years after launching the company, we have a strong foothold in the market and have highlighted the capabilities of Vietnam’s auto industry. We delivered more than 11,000 EVs in the first half of 2023.

In the right place at the right time?

Definitely. The electrification of transportation has helped us as well. In its early stages, it allows plenty of space for new brands. We at VinFast consider electrification to be the foundation for our vision: to become a global smart EV brand.

What is making VinFast competitive in this market?

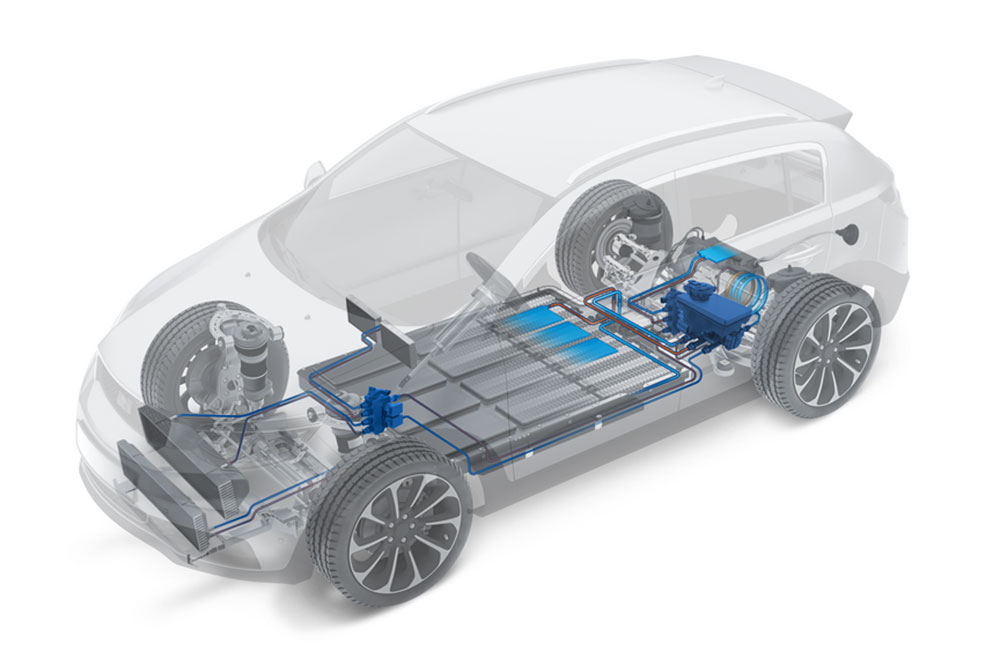

Our main asset is a comprehensive and diverse electric mobility ecosystem. Our electric car lineup covers all the popular segments, from minicars to large SUVs. They are complemented by a range of e-scooters, e-buses, advanced battery systems, and a network of charging stations across Vietnam.

How are you approaching the world market?

The first electric car produced by VinFast was a compact SUV solely intended for the domestic market. This changed in 2021 with the VF 8 model, a midsize SUV: We export it to the US and Canada. About 3,000 units have been delivered to date, which we see as a promising start. We are active in other regions as well, in Europe, for example, and have already established more than 110 showrooms worldwide.

What is the recipe for developing a state-of-the-art car today?

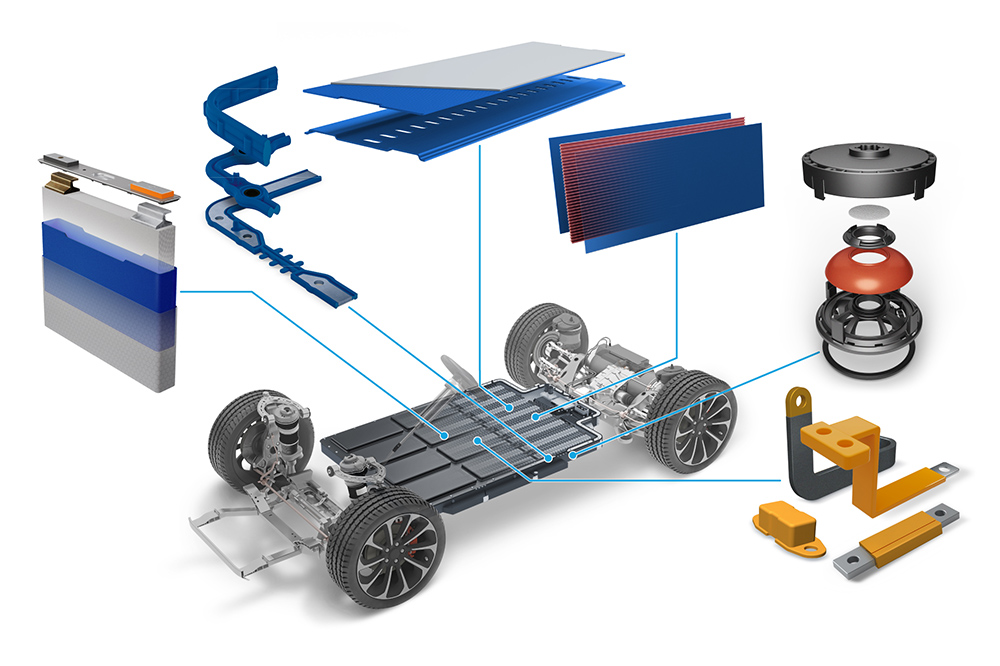

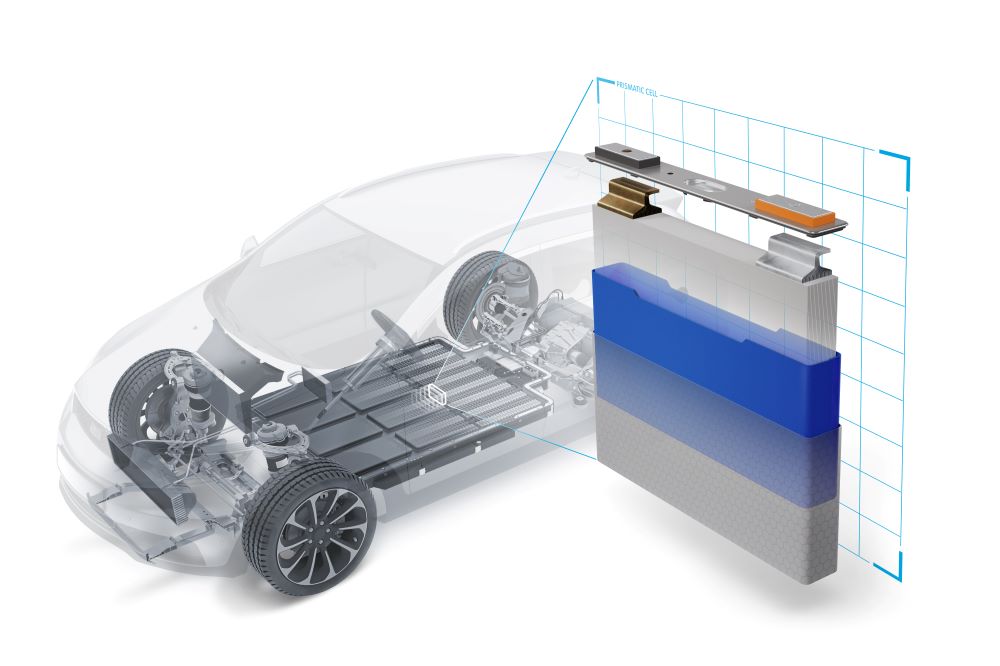

Several factors go into the VinFast recipe. First and foremost, a team of about 1,000 in-house R&D experts from Vietnam and abroad and a total Vingroup investment of US $9.3 billion for business activities and infrastructure. Another factor is Vingroup’s technology ecosystem: VinES researches and develops battery technology, charging and recycling. VinAI and VinBigData are doing research on AI and big data technology for use in the development of intelligent driving features.

Do you work with international suppliers?

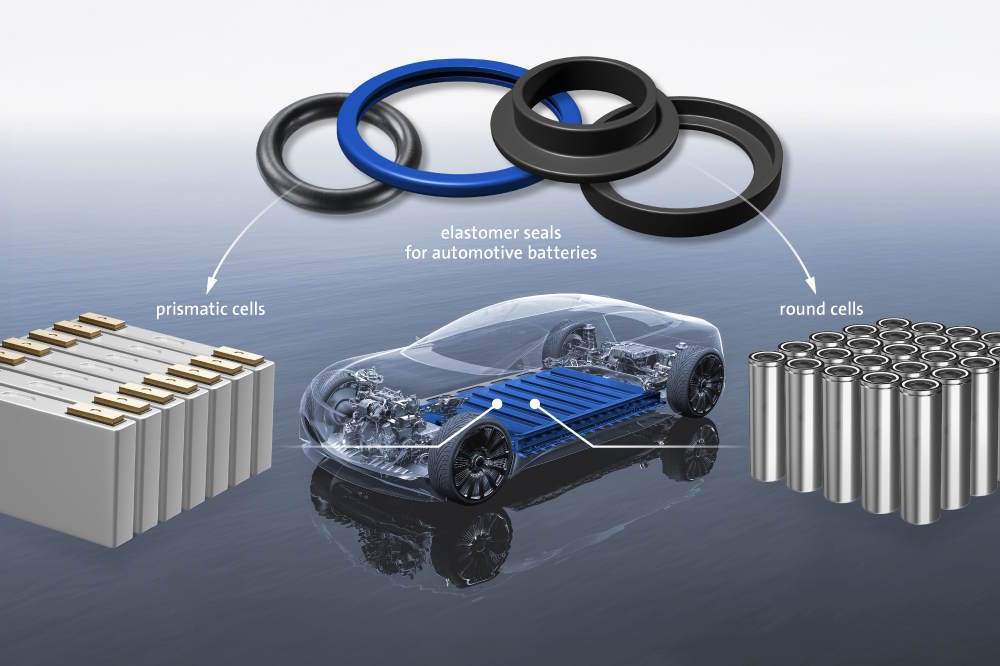

Yes, we partner with leading companies to integrate intelligence worldwide and introduce cutting- edge technologies into products while shortening development times. Some of the companies are Bosch, Siemens, Amazon and Intel. On the battery side, our partners are CATL, Gotion High-Tech and Prologium. In all, it is a recipe that allows VinFast to manufacture products that meet global standards, with the smart features that customers are demanding, like home control or mobile office.

Who develops the exterior and interior design?

Design is one of the most important sales factors. Vehicles need distinctive, unique styles. To develop them, we have collaborated with world-renowned partners, primarily Pininfarina and Torino Design, which work in the great Italian tradition of elegant car design. Our latest VF 3 is designed in collaboration with the Australian studio Gomotiv.

Could you please explain the “V” company logo?

It is a combination of our own aesthetic trademark and our national spiritual values: The “V” stands for Vietnam and Vingroup. It is reinforced by the signature light strip on the front of our cars. We would love to be a symbol of the rising aspirations of Vietnamese brands.

VinFast

VinFast is an automotive company that was founded in Vietnam. Its legal and financial headquarters are in Singapore. Established in 2017, it is a unit of Vingroup, one of the largest private conglomerates in Vietnam. The portfolio is exclusively e-vehicles. It not only has Southeast Asia in its sights – the company sees itself as a global brand. Its production plant in Hai Phong currently has a maximum capacity of 300,000 EVs per year. VinFast sources about 60 percent of its components domestically from various suppliers and is also building up production in Vietnam, for batteries, for example. This allows it to optimize production costs and vehicle prices. Another company focus is setting up a manufacturing complex in North Carolina in the United States and looking at other factory sites in line with market needs.

How do you rate the market dynamics at present?

They will stay as they are for a while. We welcome that. VinFast is building its success on this foundation. I believe electric vehicles have a promising future. More and more countries and regions are promoting electrified vehicles and setting the goal of phasing out internal combustion engines. The environment and cities will definitely be among the beneficiaries.

What does VinFast want to achieve in the coming years? Have the milestones been set?

We have already achieved one thing this year: the successful stock listing on the US market. Next is to complete the development of world-class smart electric vehicles with premium quality to meet the needs of global customers. Then, establish a strong position in the key markets of North America and Europe and expand the business globally. A lot to do – and a lot of opportunities.

More news on the subject E-Mobility

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new