Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

30.01.2024 | Story

Greater Safety for Lithium-ion Batteries

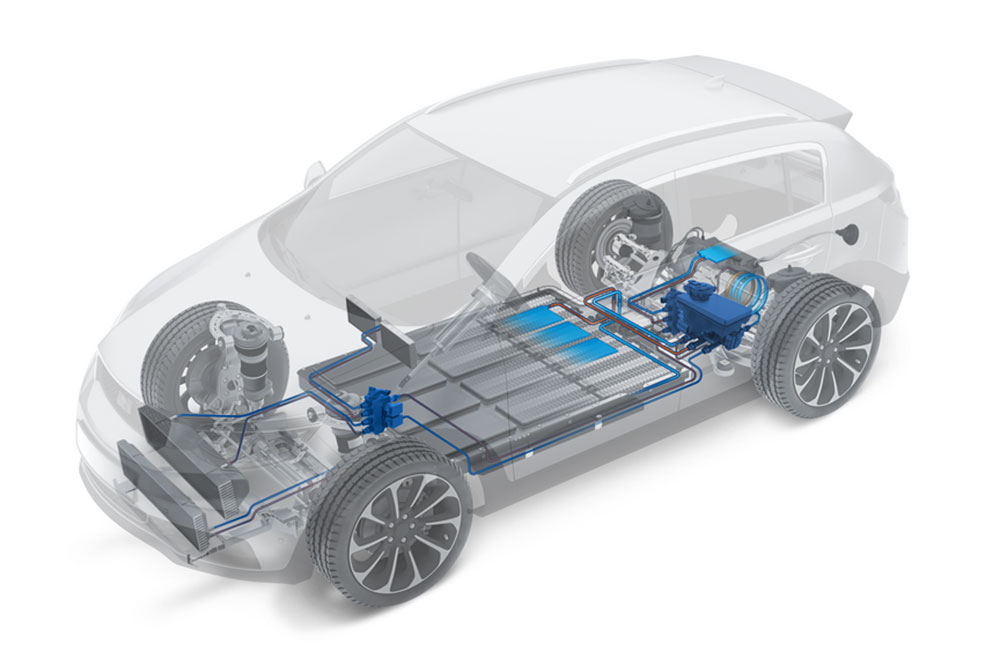

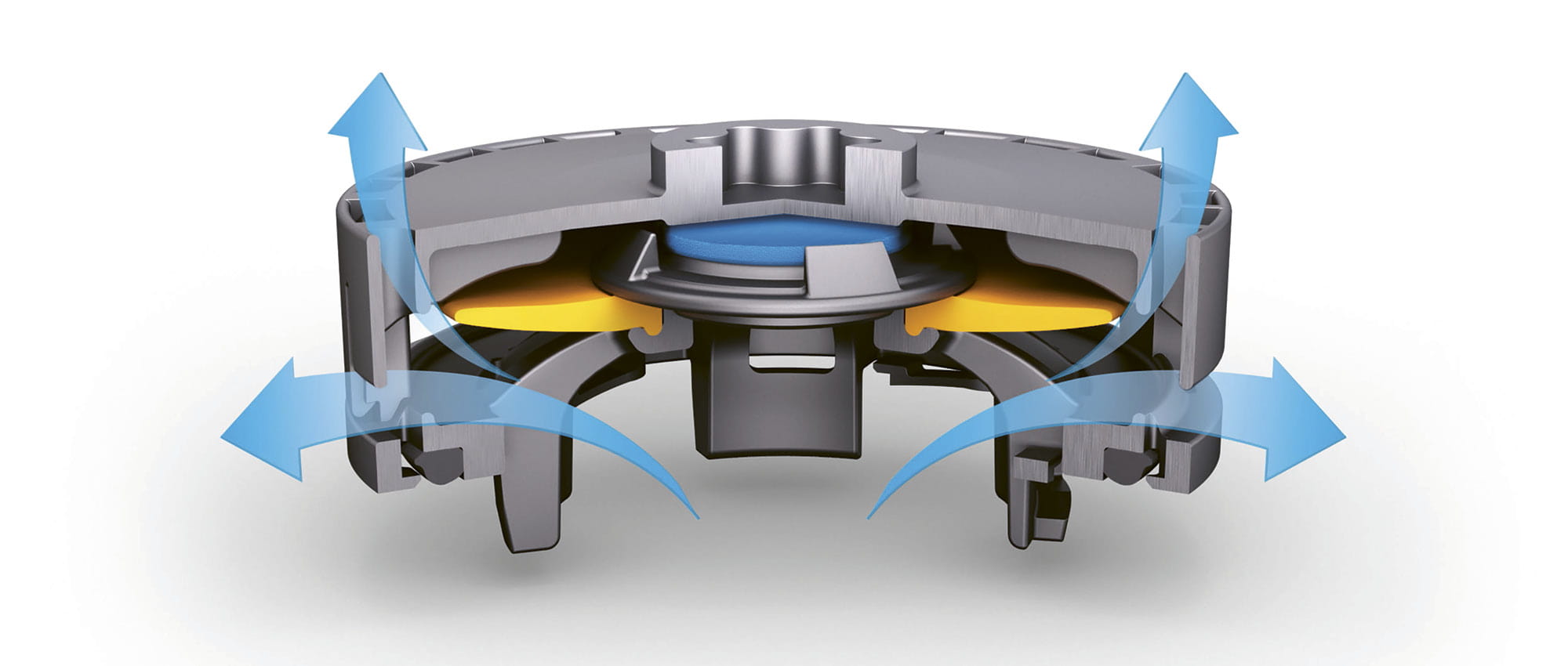

Lithium-ion batteries are at the heart of battery-electric vehicles. Their housings protect them from dust, moisture and oil. The DIAvent® Highflow from Freudenberg Sealing Technologies improves safety by equalizing pressure in the housing – during driving and emergencies.

Initial Situation

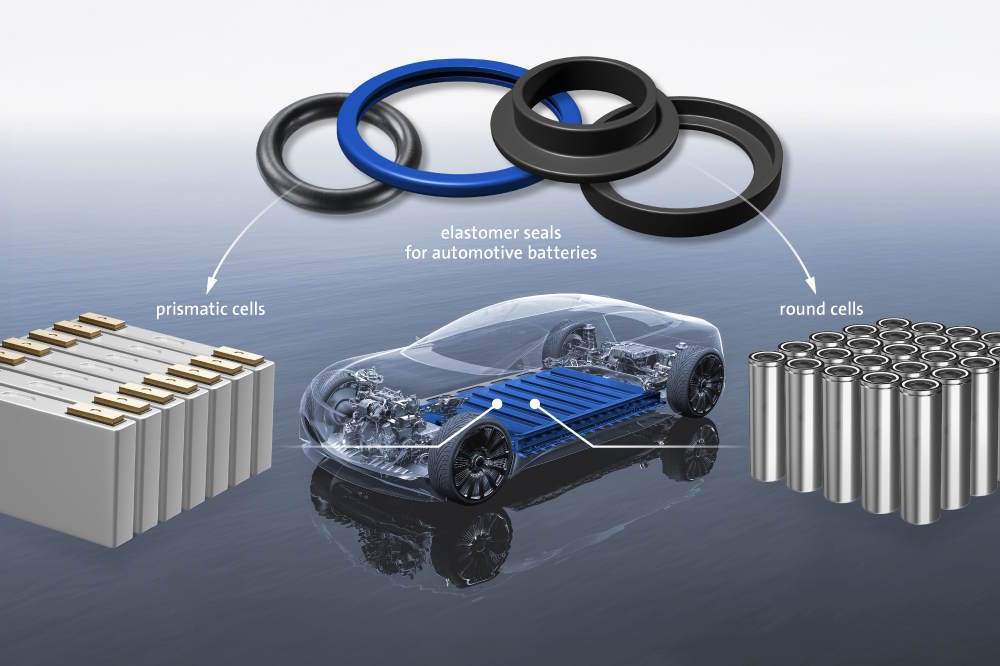

Electric cars are getting longer and longer ranges thanks to high-performance batteries. Manufacturers are packing battery cells ever more tightly to achieve this, leading to higher energy densities in battery housings. They in turn are becoming lighter, more pressure-sensitive and thinner-walled. These sensitive housings require systems that reliably equalize pressure in two scenarios: during regular operations, including driving at different elevations; and during emergencies such as thermal runaway, when the buildup of gas and pressure must be rapidly vented.

The Problem

Until now, there have been separate solutions for each scenario in the battery housing. Both had their weak points. During normal operation, a porous PTFE film handles the pressure equalization. But it is sensitive to mechanical influences. In addition, particles and fluid media can contaminate the film, which impairs its permeability and thus the battery’s “respiration.” Emergency degassing employs a rupture disc in the housing. It bursts open automatically under extreme pressures. The housing then remains open, potentially leading to the creation of a flammable gas-air mixture.

The Solution

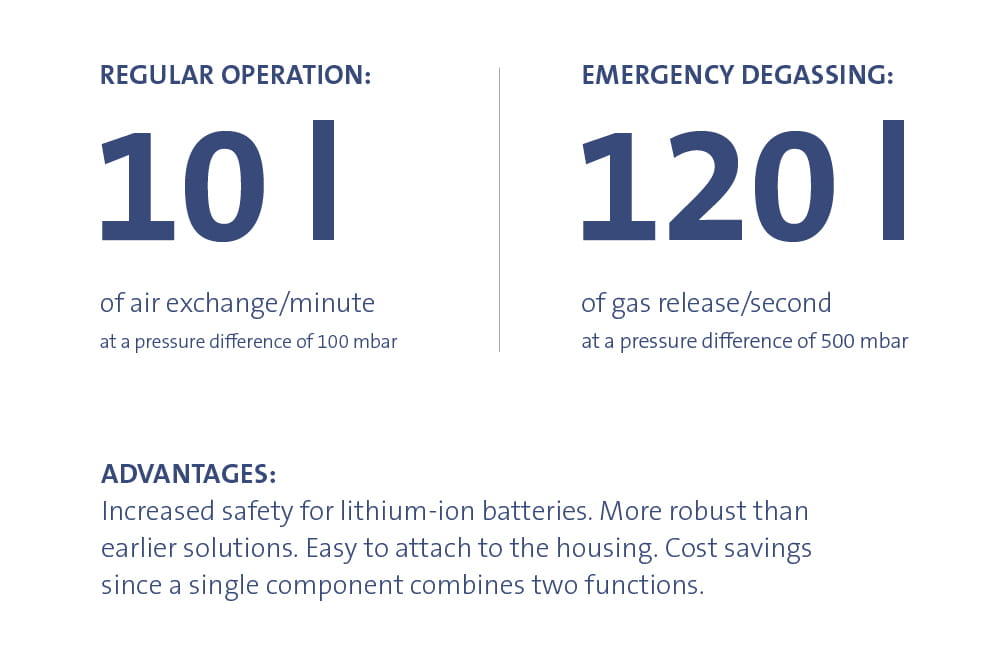

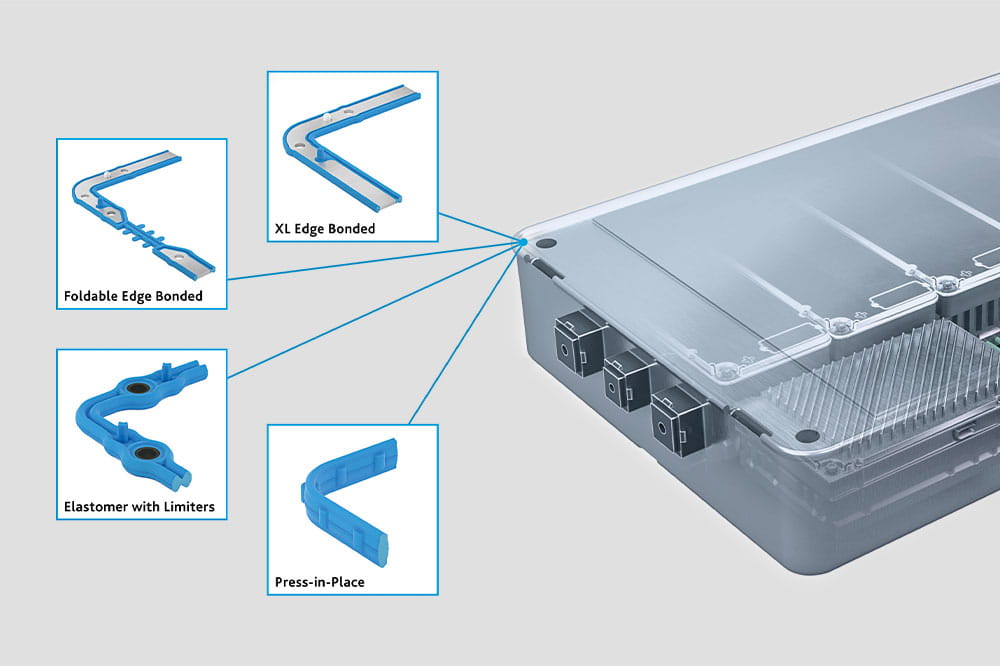

DIAvent® Highflow performs both functions and can be modified for attachment to any battery housing. During normal driving, “respirating” layers of nonwovens in the umbrella valve regulate the exchange of air and pressure. They also keep water and dirt out. In an emergency or accident, a sealing lip allows the escape of large quantities of gas. Its special silicone elastomer responds precisely to predetermined pressure differences. Once the gas escapes, the elastic sealing lip springs back and closes the housing. Short-term pressure peaks can also be cushioned in this way.

More news on the subject Automotive & Transportation

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new