Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

25.07.2025 | News

The Transformation Continues – Moving From Combustion Engines To Innovative E-Mobility Solutions

Major investments by Freudenberg Sealing Technologies and a funding initiative from the U.S. Department of Energy are boosting the production of high-tech seals for e-mobility and hydrogen applications at the Manchester, New Hampshire site.

For Freudenberg Sealing Technologies, developing products that promote the transition to electromobility and sustainable energy is a core strategic goal. This strategy is reflected in tangible actions: For example, the manufacturing operations in Manchester, New Hampshire, are being transformed. While the site has previously focused on producing gaskets for combustion engines, it will prioritize sealing solutions for battery housings and e-drive systems in the future. This shift calls for new semi- and fully-automatic production cells, expanded technological infrastructure – particularly for quality assurance – and a potential increase in the workforce.

Significant investments are also being made in research and development to ensure continued support for customers in their transition to new technologies. By innovating together with suppliers and customers, the aim is to develop cutting-edge solutions that meet the evolving needs of customers.

“With the next-generation production cells we plan to implement through 2029, we’ll be able to significantly increase our output and meet the growing demands of our customers,” says Soeren Schmitz, Vice President of the Gaskets lead center at Freudenberg Sealing Technologies and Site Manager in Manchester. Once the transformation is complete, the site aims to manufacture over 100 million gaskets per year in mass production.

Wide product range

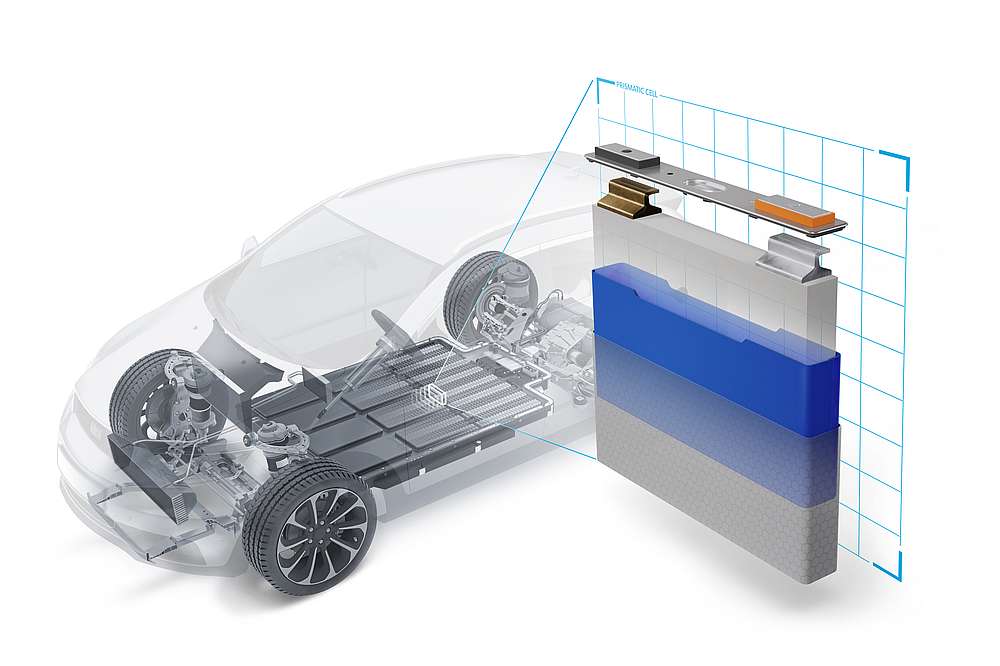

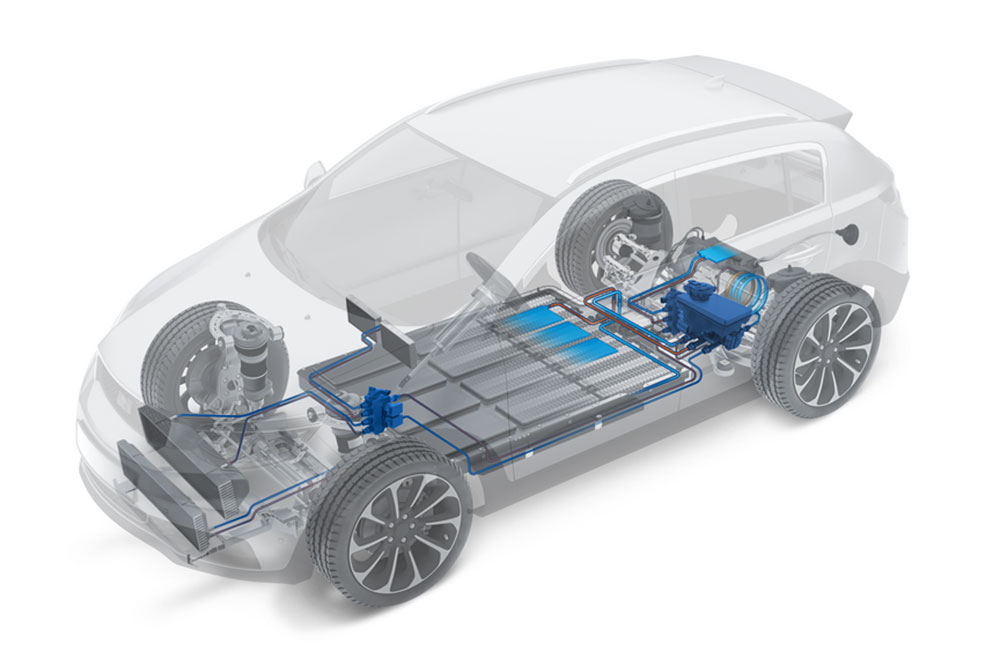

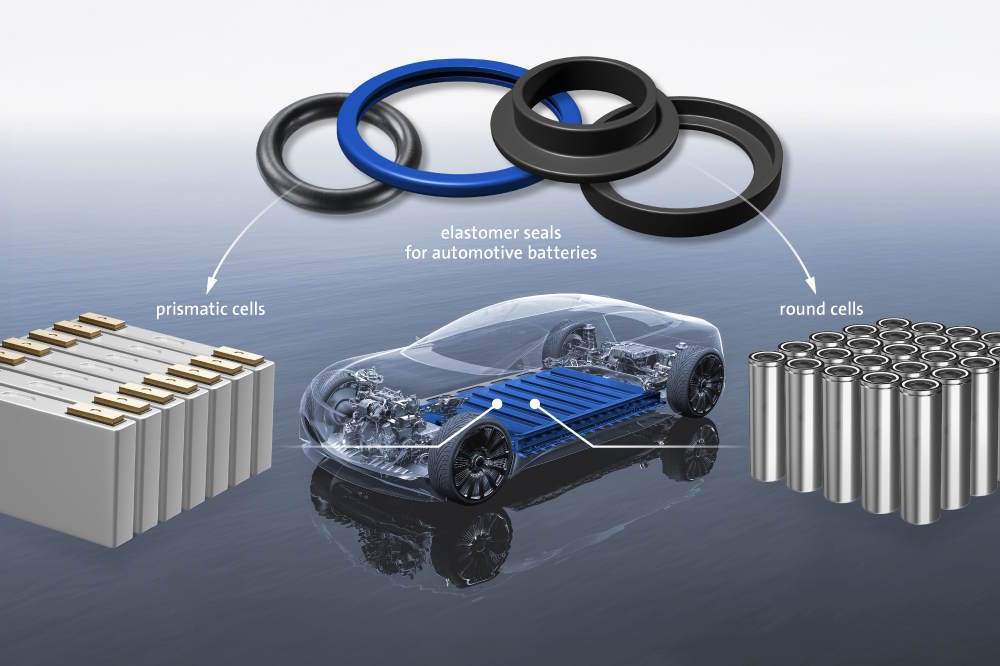

Freudenberg designs and manufactures products from proprietary high-performance materials for battery housings at this site that enhance safety, efficiency and durability of electric vehicle components.

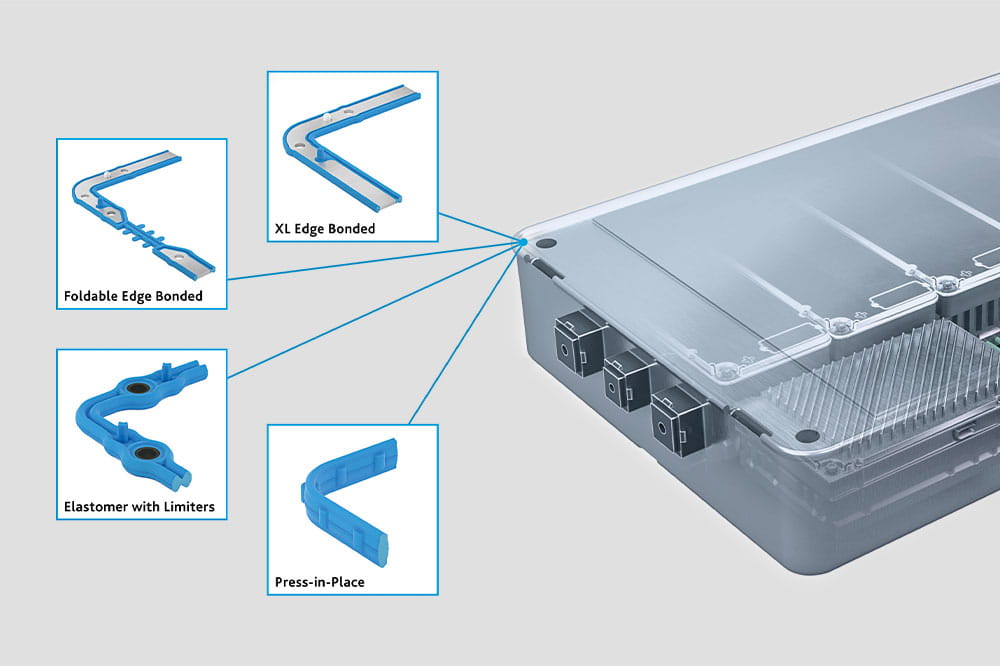

The company produces custom solutions for sealing batteries and integrated powertrain units, such as inverters, onboard chargers and gearbox housing with a focus on performance and reliability, especially preventing corrosion. The extensive portfolio includes rubber gaskets and rubber + metal solutions, such as edge-bonded gaskets, covers with integrated gaskets, and XXL edge-bonded gaskets.

Funding from the U.S. government

A sum in the double-digit millions will be invested in transforming the Manchester site – to strengthen its innovative power, for new equipment, and for the preservation and even demand-based expansion of jobs. The U.S. Department of Energy was convinced by the site’s detailed strategic roadmap and is supporting its transformation. Last year, the Department launched its 48C program with a competition for tax credits for investments in clean energy and decarbonization – which was won by the Manchester site. The goal of this program is to encourage investments in sustainable energy, bolster domestic manufacturing and U.S. competitiveness against low-wage countries, and secure jobs at home.

Explore Our Advanced E-Mobility Solutions

Further information regarding gasket technologies for robust sealing that enhance manufacturability, serviceability, and end-of-life disassembly can be found here:

Battery Sealing Gaskets for CarsMore news on the subject Automotive & Transportation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.