Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

04.02.2025 | Story

A High-Pressure Gasket With an Innovative Design for PEM Electrolyzers.

Durable, high-performance seals are a key to producing hydrogen with electrolyzers, and the right designs are crucial. Freudenberg Sealing Technologies is scoring points with a novel high-pressure gasket.

Initial Situation

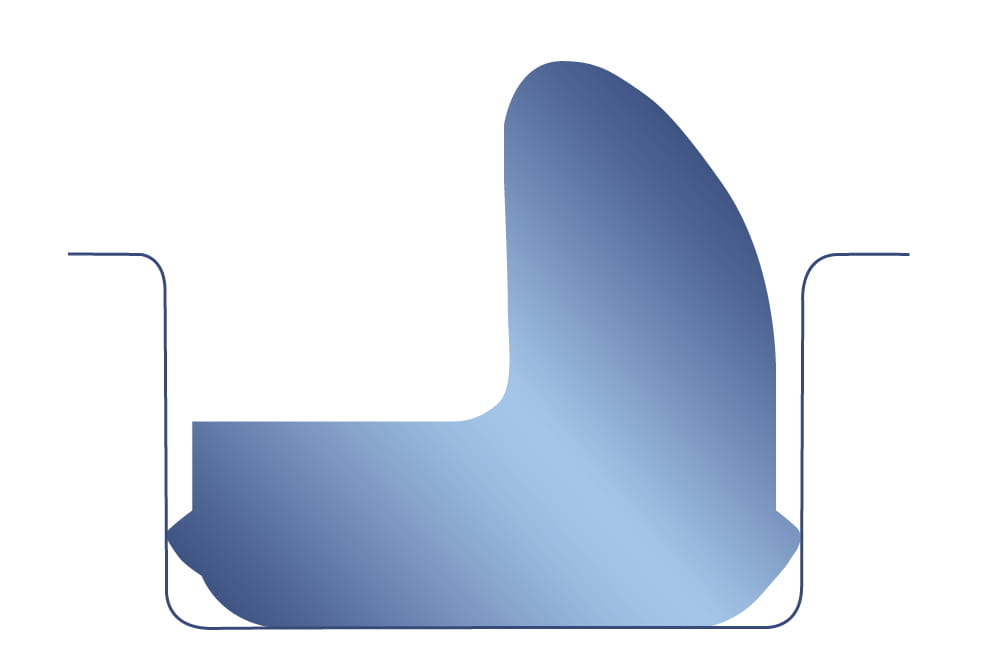

Lock: Cross-section of the gasket during the assembly process into the groove of the cell frame. The retaining features on both sides hold the gasket in place.

Different forms of electrolysis are suited to various purposes. Electrolyzers with a polymer electrolyte membrane (PEM) stand out for their fast cold starts and quick response times. For example, they are especially suited to applications where electric current has to be drawn off in the shortest possible time. That’s the case with electricity from wind turbines, whose output naturally fluctuates. PEM electrolyzers have a market share of about 30% worldwide, and that percentage is rising – not least of all because the underlying technology is becoming more mature.

The Problem

Gaskets in PEM electrolyzers are important safety components. After all, they seal off electrolytic cells from one another, ensuring that the gaps in bipolar plates are sealed. They also prevent gases and liquid media from escaping into the environment. Standard gaskets like those used in the automotive industry are totally unsuited for electrolyzers due to the increased pressures that are involved. To seal the cells against each other, the gaskets must be inserted into grooves in the cell frame. The gasket’s instability in the groove turned out to be a drawback at high pressures.

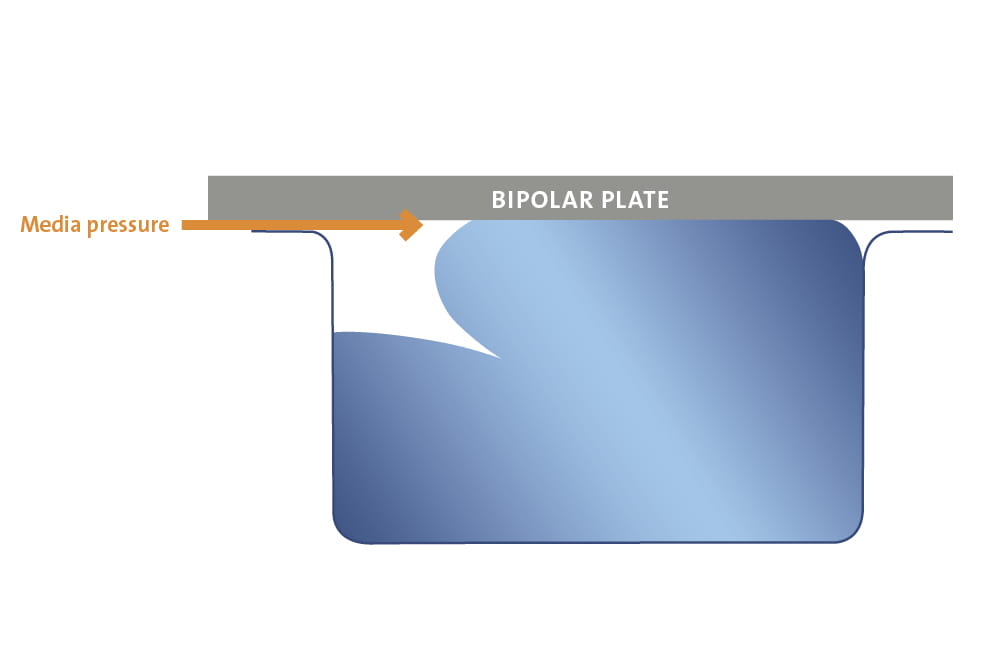

Barrier Effect : Cross-section of the gasket when installed. In electrolysis operation, high pressure activates the gasket. A possible gap between the bipolar plate and the cell frame is sealed.

The Solution

Freudenberg Sealing Technologies focused on the gasket design. The new gasket has been given small retaining features on both sides to lock it into the groove. This holds the part in place after assembly. Engineers selected a novel L-shape for its cross-section. As soon as the electrolyzer is in operation, the pressure rises in its interior and activates the gasket, which then assumes a C-shape. The gasket’s contact pressure increases to make it a reliable barrier. The high-pressure gasket impressed customers when they tested it themselves, and they are already using it in series production.

This article originally appeared in ESSENTIAL, Freudenberg Sealing Technologies’ corporate magazine that covers trends, industries and new ideas.

More news on the subject Technology & Innovation

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new