Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

22.03.2024 | News

Ensure purity in your food & beverage application with our Simmerring® Radiamatic HTS II

Our process industries solutions solve some of the biggest challenges in the food and beverage industry. Learn how we helped a United States manufacturer meet the demanding needs of their customers.

The food and beverage industry is very demanding with strict purity standards for anything that may come into contact with the product. This holds true for the gearboxes that are used in many applications within the industry. With a diverse portfolio of products specially designed for the process industries, Freudenberg Sealing Technologies is well-positioned to support your unique needs.

The Challenge

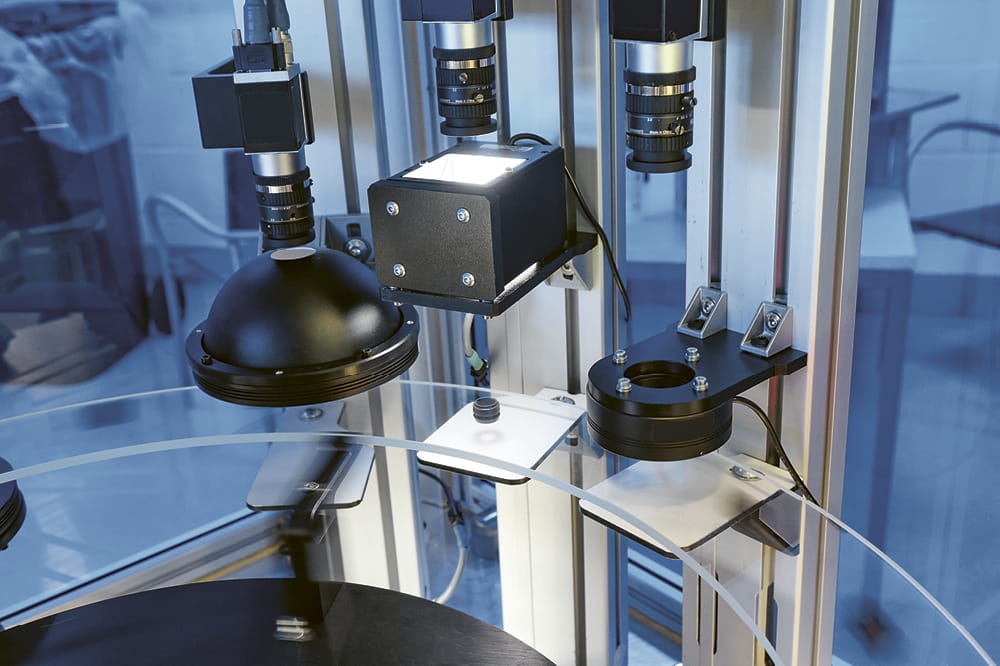

A leading producer of hygienic-designed gearboxes was looking for a shaft seal capable of withstanding the chemicals, media, and corrosion resistance with IP69K protection that meets hygienic standards as it would come into direct contact with food. IP69K ratings are given to equipment and seals based on their ability to withstand intensive cleaning with harsh chemicals, along with high pressures and temperatures. IP69K products are particularly useful and sought after for applications where sanitation is the primary concern such as those in the pharmaceutical, or food and beverage space.

Furthermore, the end users of the equipment required that they meet US FDA, European EHEDG, and NSF which is an independent certification so they can show their customers that they only use the highest quality hygienic products in their manufacturing process. When you are working with an application where items manufactured will be consumed by a person or animal your seal has to perform at a high level under stress without failure to prevent any contamination from getting into the product.

The Solution

After continued struggles, the manufacturer reached out to one of our distributors in the United States who quickly recruited the support of our experts. As a first step, our team conducted a detailed analysis to understand the application and the unique requirements of how they were utilizing their equipment.

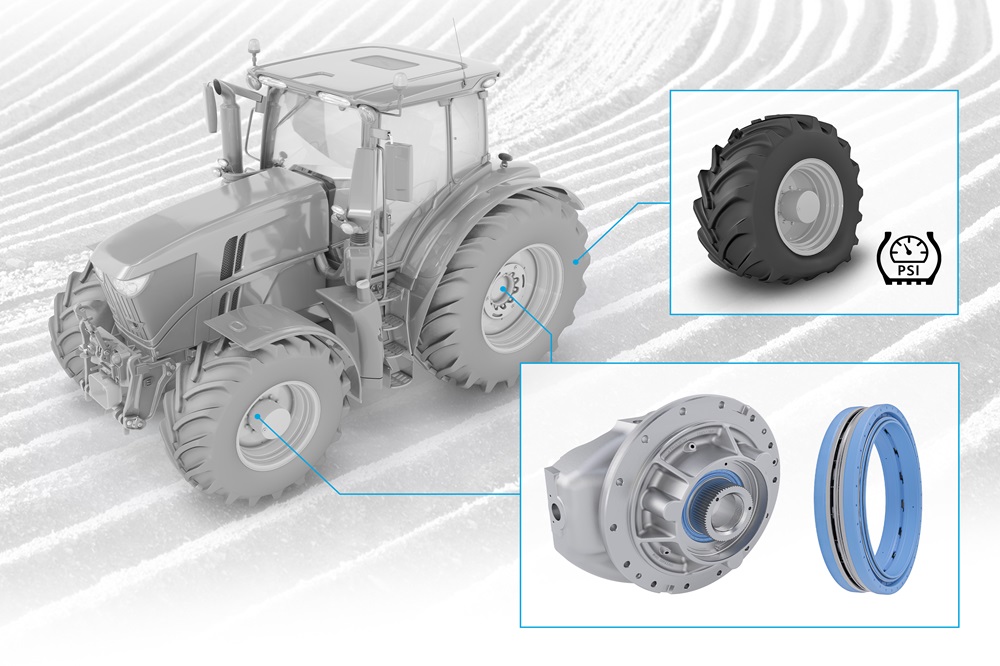

Once our distributor in the United States reached out our team was quickly able to review all the unique aspects of the gearboxes to come up with a solution. We identified a specialized solution from our process industries portfolio: the Simmerring® Radiamatic HTS II. The Radiamatic HTS II shaft seal rings offer multifaceted options for use in the process industry. This special development made of PTFE is distinguished by its lip's low contact pressure on the shaft and, as a result, low frictional losses.

With its design specially for dynamic sealing in rotating components at high temperatures fast circumferential speeds, the PTFE material offered outstanding chemical resistance to the variety of process liquids, gases, and cleaning agents used in the gearbox. This quick development allowed the gearbox manufacturer to quickly get back to making quality products that meet all the requirements their customers had for them. All of this is possible while the manufacturer received around $35,000 of annual cost savings and a reliable source of their seals for both the manufacturing and repairing of their gearboxes.

Benefits of the Simmerring® Radiamatic HTS II

-

Well-suited to hygienic applications

-

Comes in materials with high chemical, temperature, media, and corrosion resistance

-

Provides increased food safety

-

Provides you peace of mind

-

Meets FDA, EHEDG, and NSF standards

-

Reliable supply chain and value for easy maintenance and repair of equipment

Learn more about Radial Shaft Seals on foodandbeverage.fst.com open_in_new

More news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.