Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

19.06.2024 | News

Shaft Repair Sleeves: The Perfect Compliment

Don’t leave money on the table, our shaft repair sleeves deliver an excellent return on investment by extending the lifespan of your equipment’s shaft.

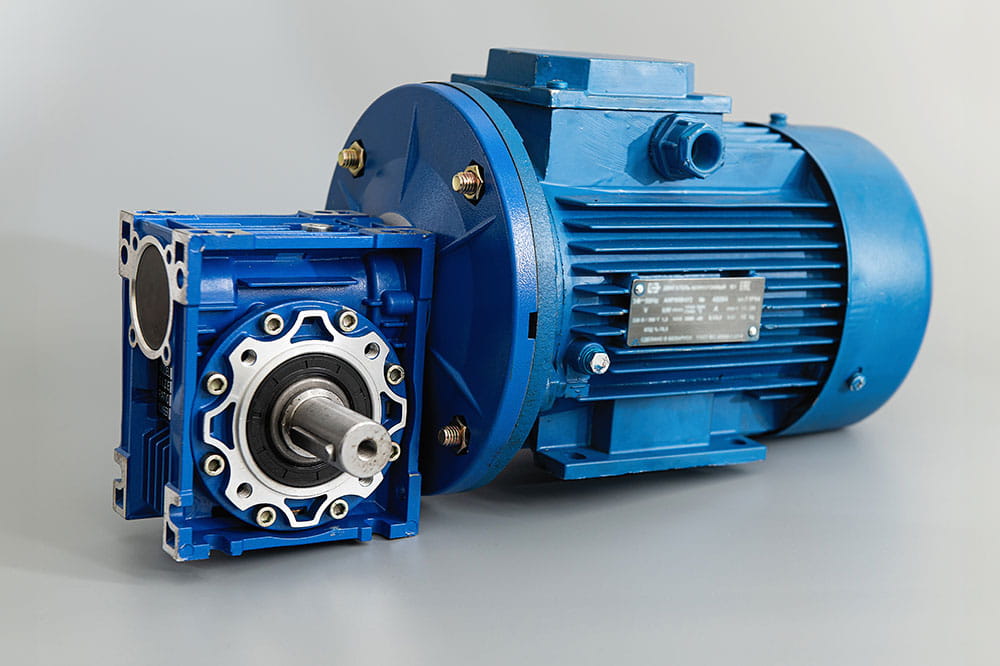

You likely already know that radial shaft seals play a crucial role in a wide range of industrial applications by preventing leakage of fluids along rotational shafts. Today, these seals are crucial for your equipment, but despite this, they must be on a shaft that is in at least relatively decent condition otherwise the sealing ability could be at risk even with the highest quality seal. Operators of equipment with radial shaft seals often find themselves in situations where their shafts require time-consuming and expensive repairs or even replacement. What is less known is there is a cost-effective solution that can greatly extend the lifespan of the shafts in their equipment while still using the same seal they have always used. This may seem too good to be true, but it is a reality with shaft repair sleeves, this solution provides tremendous value allowing you to get your money’s worth out of your equipment without breaking the bank.

What Is a Shaft Repair Sleeve?

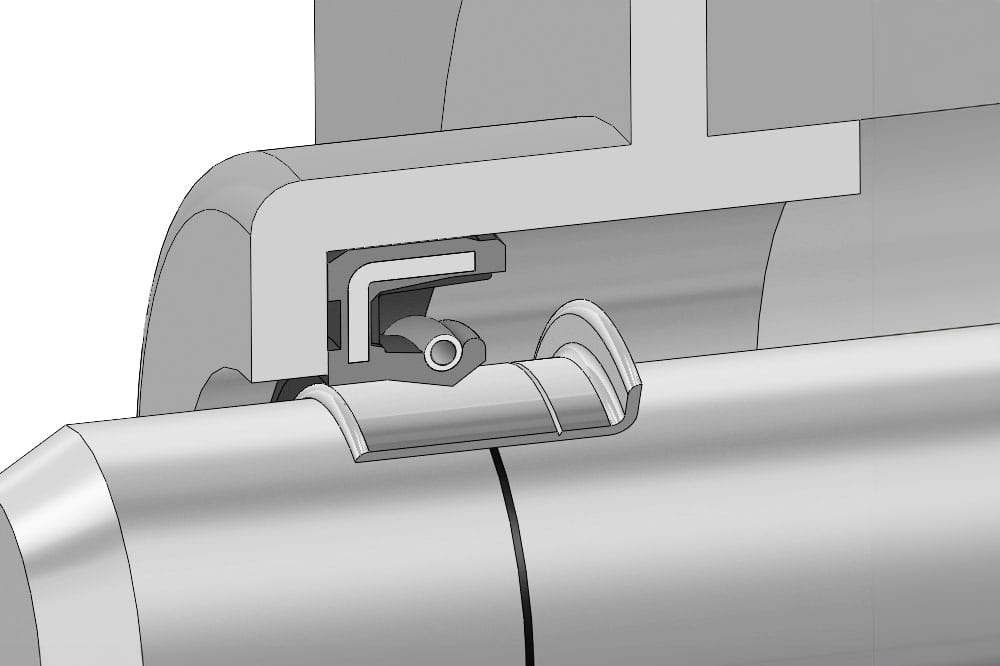

Shaft repair sleeves are used on shafts that are badly worn or degraded or can alternatively be used in new applications to protect the shaft from the beginning. A shaft repair sleeve is a thin metal sleeve that is inserted over the worn surface of the shaft. Once the shaft has been installed it acts as a running surface for the radial shaft seal instead of the shaft itself. Using a shaft repair sleeve is a fast and cost-effective solution to extend the useful life of the shaft without the need to do time-consuming and costly repairs or replacement of the shaft. Wherever you utilize a radial shaft seal is somewhere you should consider adding a repair sleeve to extend the lifespan of the shaft.

Why Use a Shaft Repair Sleeve?

Once a shaft becomes damaged getting a tight seal can be difficult or even sometimes impossible no matter the quality of the seal. This can occur for several reasons, first, the surface becomes too inconsistent for the seal to form a tight sealing surface, secondly, if the shaft becomes damaged any sharp edges could damage the seal causing it to fail. Over time a radial shaft seal will wear grooves into a shaft due to constant rotation, oscillation, and pressure. Once you reach this point you have only two viable options. You can decide to remove the shaft where you can now replace or re-machine the surface of the shaft. Both of these options are time-consuming losing your productivity, and very costly. The other option is to install a shaft repair sleeve, this solution offers quick installation, the ability to be replaced with new repair sleeves, and is available at a fraction of the cost. When you have very expensive equipment, you want to keep it operating and have as long of a lifespan as possible to get a good return on your investment.

Benefits of Shaft Repair Sleeves

-

Economical rebuilding of the shaft running surface

-

No costly machine downtime

-

Fits tightly on the shaft

-

Original seal size does not change

-

Simple and fast process (Installs in minutes)

-

Wear-resistant surface and delivers a good lifetime

-

Rust and acid-resistant steel

-

Shaft repair sleeves cover the operating parameters for all catalog radial shaft seals

-

The radial shaft seal’s running surface is rebuilt permanently with full functionality

-

Can prevent shaft surface wear when applied from the beginning

What Brand Can I Use This With?

While a shaft repair sleeve is a Dichtomatik brand product you can use it in conjunction with any radial shaft seal including our Freudenberg brand Simmerring® and our Dichtomatik brand radial shaft seals. While the sealing capabilities and properties can vary between our brands the shaft repair sleeve does not impact the functionality, performance, or lifespan of the seal. Since the sleeve functions in the same way as the shaft, the radial shaft seal performs exactly how it would on the shaft itself. The only real change is the seal occurs on the repair sleeve instead of the original shaft that is covered by the repair sleeve.

Is a Shaft Repair Sleeve and a Shaft-Eze the Same Thing?

You likely have heard many different names for a shaft repair sleeve, most of which are a trade or brand name associated with the shaft repair sleeve manufacturer. Within the Freudenberg Sealing Technologies portfolio, we offer either Shaft-Eze or shaft repair sleeves depending on where you are located. These are the same product, Shaft-Eze is simply a brand name for a shaft repair sleeve used in the United States, Canada, and Mexico. The only difference is that Shaft-Eze tends to have more imperial sizes available that may not be available outside of the North American market.

Equipment Repair Solutions

Shaft repair sleeves of the Dichtomatik brand are one of the many solutions within our equipment repair solutions portfolio at Freudenberg Sealing Technologies. With a wide variety of repair products and service offerings, we have the solution you need to get your equipment back up and running.

Learn more about our equipment repair offerings

Shaft repair sleeves are the perfect compliment to your radial shaft seal because they can simply be added to anywhere you currently use a radial shaft seal. When you buy a radial shaft seal it simply makes financial sense to add a shaft repair sleeve when you think about the lifetime cost of ownership. With their ability to greatly improve the lifespan of your equipment’s shaft, our repair sleeves are the perfect complement to your radial shaft seals. Find the right repair sleeve to compliment your radial shaft seal with our Product Catalog or get in touch with our sealing experts!

More news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.