Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

15.08.2023 | Story

The Brewing Process Makes the Difference

Coffee is a popular energy booster. But how much energy goes into coffee on its path from the field to the steaming cup on your table? Answers to an interesting question.

Coffee drinkers know the signals: Something is hissing and bubbling in the kitchen, and an aroma is circulating through the room. You have a steaming cup in front of you a short time later. The first sip is a delight. Or just a welcome burst of energy. Coffee is the most popular drink in many countries. About 2.25 billion cups are consumed worldwide each day. Caffeine is the most potent ingredient of this pick-me-up. It blocks the effect of adenosine, a neurotransmitter, producing the sense of being wide-awake.

59.1 Grams of CO2 per Cup

But how much energy goes into this beloved energy booster as it travels from the field to the coffee cup? A few numbers for orientation: For example, the German coffee company Tchibo determined the CO2 footprint of a type of roasted coffee not long ago. On average, it turned out to be 59.1 grams of CO2 per cup. That figure can be broken down at each step. The cultivation of the plants accounted for the largest portion, 33 grams, including fertilizer and crop protection agents. Following that was the preparation of the coffee at 18 grams on average. Depending on the process, the figure could range from 10 to 60 grams of CO2 per cup. Taken together, ocean transport, roasting and packaging come in just under 4 grams. Another 4.3 grams of the total relates to the beans’ delivery to the sales point, the consumer’s trip to the store, and finally the disposal of the coffee grounds into the organic waste bin.

Power Consumption as a Factor

An electric kettle is the most energy efficient way to brew coffee. About 70 watt hours go into the preparation of a single cup. That was the finding of a study commissioned by the World Wildlife Fund of Switzerland and the Zurich district’s electric power station. The electric kettle was followed by the drip coffee maker, the pod machine and the fully automatic coffee maker with about 100 watt hours. The biggest user was a mocha coffee pot with a glass-ceramic cooking plate, registering 250 watt hours per cup. Consumers thus have a major impact on the CO2 footprint of their coffee consumption. The issues are straightforward technically, but not always emotionally. One person swears by coffee from a drip machine as his energy booster, another prefers classic espresso and the third sings the praises of the French press. Electricity from renewable sources can significantly reduce a CO2 footprint, and there are other ways to reduce the CO2 emissions generated by a cup of coffee, such as your choice of a cup or mug when you enjoy the drink away from your home. It makes a difference whether it is a single- or multiple-use cup. The CO2 footprint is also less if you substitute a plant-based alternative for standard milk.

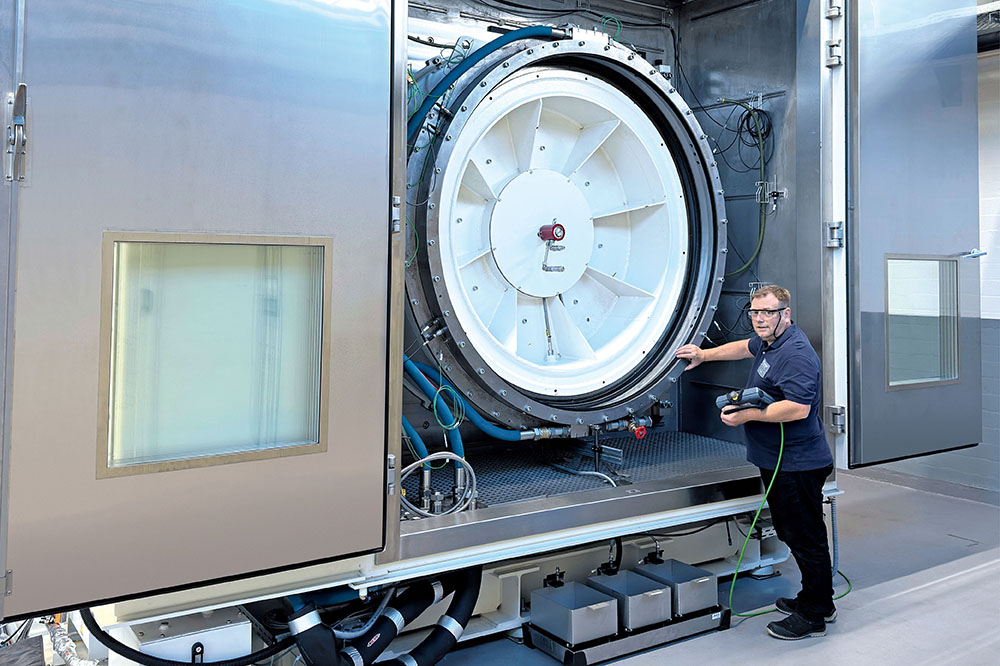

Seals for a Better Experience

From the fields to the cup: Many Freudenberg Sealing Technologies products are used at many points in food production, and the coffee business is no exception. One goal is to improve energy efficiency. Among other areas, the products can be found at the end of the chain. Micro seals in fully automatic coffee machines are one example. After all, the devices are small, complex processing systems in and of themselves.

The Tea Drinker’s Advantage

Some of the factors cited here clearly apply to tea, although it is considered markedly more environmentally friendly than coffee. Experts say tea production uses nine times less land than coffee cultivation, when everything is taken into consideration. Its processing is also less energy intensive. Coffee beans are dried, washed, roasted and ground. Tea leaves, by contrast, are merely rolled after the harvest and then dried with hot air. And that’s it. Taken together, the harvest, rolling, drying and transport represent about 20 percent of the overall energy consumption. Boiling the water for tea represents 80 percent of the total energy input. So, is it time to switch to tea? That’s not an option for a true coffee lover. It would be better to consider how changes in your daily behavior could improve your personal CO2 footprint. Which is not a bad thing anyway.

More news on the subject Renewable Energies

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new