Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

09.02.2021 | Story

High and Low

Highly flexible factory automation – known as “Industry 4.0” – was supposed to make manufacturing more attractive in Europe and the United States. So far though, only a few companies have moved production back from low-cost countries. Has something gone awry?

The net gain was 200 bolts of cloth and 125 barrels of wine. At the start of the 19th century, the British economist David Ricardo chose a graphic example to con- vey the merits of his theory of comparative cost advantage to his compatriots. If Portugal totally devoted itself to wine production, and England to cloth-making, and the two countries wanted to engage in commercial trade, labor productivity in each country would rise – and prosperity would increase noticeably. But consider something that Ricardo could not imagine: What would happen if human labor were no longer needed to produce cloth or wine?

With the advance of manufacturing automation since the 1980s, some industry sectors have approached this theoretical state. Robots took over increasingly complex tasks at high wage locations. But automation has a downside: It requires a major investment at the outset. Moreover, with their high flexibility, humans are far superior to fully automatic machines programmed for a specific activity if the work involves the manufacture of just a few products – or if they are extremely customized. That’s why highly labor-intensive activities have been moved to low-wage locations as globalization has progressed – from the United States to Mexico, from Western to Eastern Europe and more recently from Chinese coastal cities to the hinter- lands. This migration has long seemed unstoppable. No company with competitors could afford to turn its back on the cost advantages that relocation offered.

Back to the Future

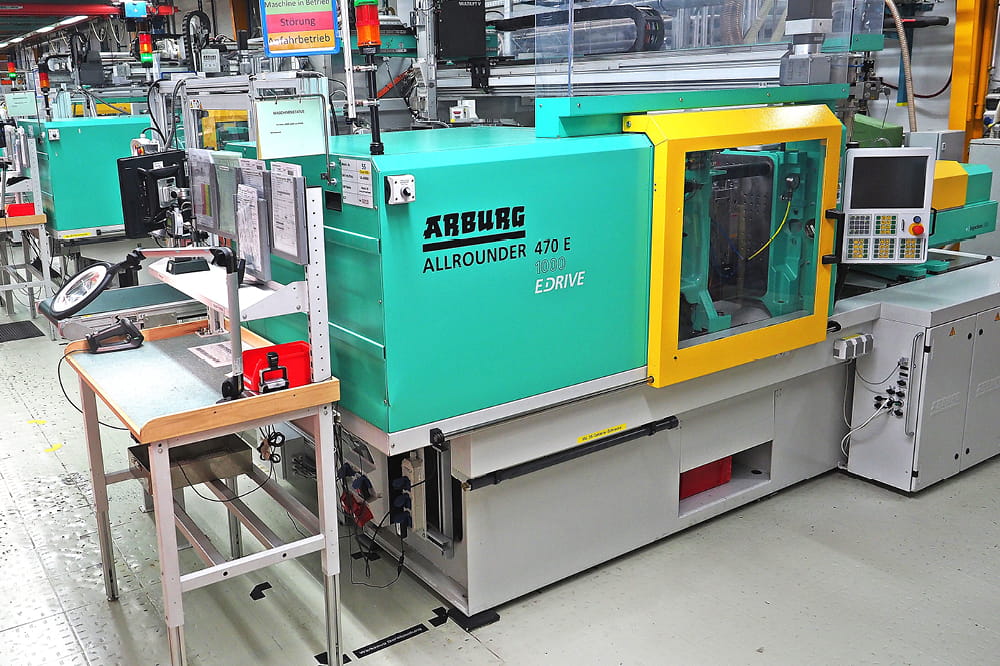

Then “Industry 4.0” came along. It was the vision of completely networked and highly flexible manufacturing. It was supposed to make automation profitable all the way down to a single batch from a single tool. Promoted for the first time at the Hannover Messe in 2011, Industry 4.0 was not only designed to improve the competitiveness of German industry – it was supposed to promote “reshoring”, that is, the re-transfer of industrial production back to high wage countries. Nearly a decade later, it’s reasonable to ask whether the concept has worked. Figures from the World Bank are unequivocal: In 2010, the production of goods accounted for a 20 percent share of Germany’s gross domestic product. The figure for 2019 was 19 percent. In the United States, where similar automation concepts were advanced as the “Industrial Internet,” the manufacturing share of its gross domestic product fell from 12 to 11 percent. Fraunhofer researcher Jürgen Jasperneite cites some important reasons for the sobering interim results: “You simply can’t buy this kind of highly adaptable equipment yet. In addition, I have always wondered what products definitely require this capability.” The criticism comes from an authoritative source: Jasperneite launched the Smart Factory OWL in Lemgo in 2016 and is considered a leading expert on industrial automation. He sees the merger of information, communication and production technology as an ongoing process. “There has been no huge leap in productivity due to Industry 4.0 but rather constant improvement as new technologies are systematically implemented.”

It is still absolutely impossible to buy this kind of adaptable system today.

Prof. Dr.-Ing. Jürgen Jasperneite – Director of the Industrial Automation branch Fraunhofer IOSB-INA

No Magic Bullet

The main purpose of the model factory in Ostwestfalen-Lippe is to support small- and medium-sized companies. Crowds of business owners and experts make their pilgrimages to Lemgo, look at demonstrations of new technological building blocks and have their own manufacturing operations analyzed to deter- mine their level of maturity. Ideas for joint projects emerge again and again. For example, the researchers helped one manufacturer of electric drives develop a system to monitor the condition of his products from a smart phone app. In- stead of grand visions, Jasperneite is also pursuing concrete projects with a practical artificial intelligence lab for automation and production that just went into operation. He also says any expectation of a magic bullet is misplaced. “A fully autonomous and adaptive pro- duction control system can be the icing on the cake in a competitive situation. But in many cases, humans are still the first choice.”

More news on the subject Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new