Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

22.03.2022 | Story

Make Water From Hydrogen and Oxygen Into Hydrogen Fuel

In Korea, it is customary for relatives to give the bride and bridegroom wooden ducks. Why? Because these water fowl are thought to form especially strong bonds. The wooden ducks stand for the newlyweds’ marriage.

Elements such as hydrogen and oxygen also enter into close bonds – they join together to create water, and it takes a great deal of effort and energy to separate them. Hydrogen itself is exceedingly volatile. It is normally colorless and tasteless. Its gas molecule is made of two atoms that can be stored under high pressure – preferably in painstakingly sealed tanks or gas bottles. In fact, hydrogen wants nothing more than to reconnect with oxygen to become liquid water again. In the process, the hydrogen releases some of the energy expended during the separation -- an effect that can be used to produce and consume energy in a climate-neutral cycle.

STATION 1 |

WATER FUNDAMENTALS

As mentioned, water is composed of hydrogen and oxygen. One oxygen atom and two hydrogen atoms form a water molecule. In nature, water usually contains dissolved gases, organic compounds and salts. In all, 71 percent of the earth’s surface is covered by water. The total water volume is 1.4 billion cubic kilometers, 3.5 percent of which is freshwater. That corresponds to 48 million cubic kilometers. If this amount of water were compressed into a cube, the length of its edges would be a whopping 363 kilometers. So water exists in huge quantities on the planet, but it is unequally distributed.

STATION 2 |

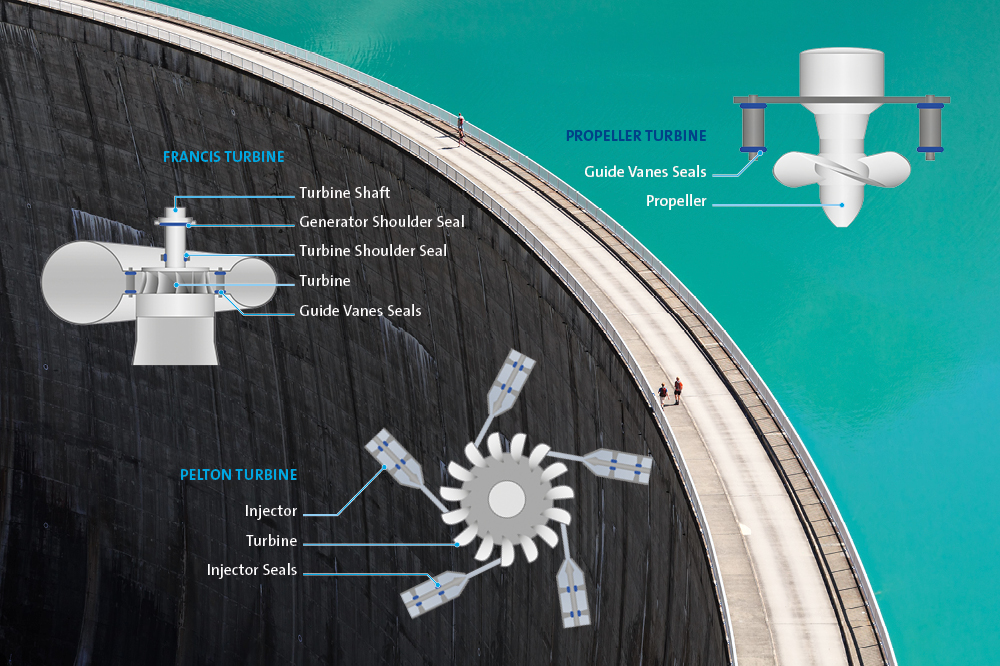

CLIMATE-NEUTRAL ELECTRICITY GENERATION

Electricity can be produced with hydropower – or with solar and wind energy. Companies and consumers receive the electric power generated by these means. In favorable weather conditions – for example, during sunny periods or on windy autumn days – it is possible to produce more electricity than is needed. The impact can be increased by expanding renewable facilities within a country. The surplus electricity can either be used immediately or stored. And this is where hydrogen comes in. Excess electricity can be used to produce hydrogen via electrolysis in special facilities.

STATION 3 |

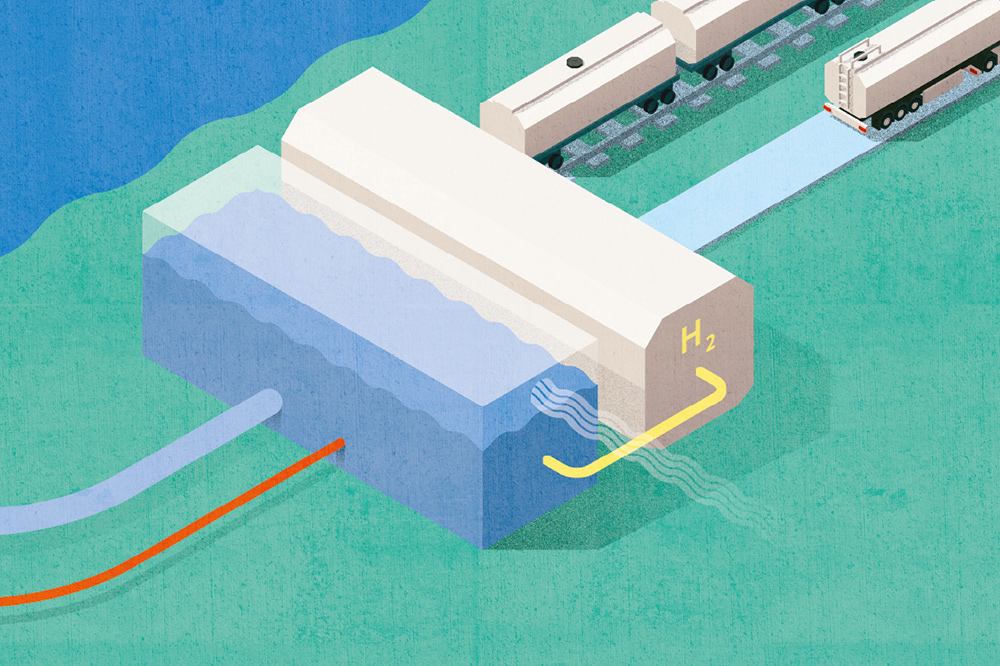

ELECTROLYSIS FACILITY

What exactly happens in an electrolysis system? Electricity is applied to the water inside it. The energy separates the water into oxygen and hydrogen. As a rule, freshwater is used for this. But researchers are already working on catalytic converters that could use seawater for hydrogen electrolysis. Today established facilities are turning to a process using a membrane that is only permeable to protons. The membrane functions as a separator positioned between the cathode and the anode. In essence, a fuel cell, only in reverse. If voltage from outside is applied, it causes the water’s decomposition at the anode. Hydrogen ions, free electrons and oxygen are the result. Only the hydrogen ions travel through the membrane to reach the cathode. There they combine with the free electrons to create hydrogen.

STATION 4 |

HYDROGEN TRANSPORT

Vehicles propelled by fuel cells can be powered by hydrogen. This involves the delivery of the gas from the electrolysis facility to the consumer. Special railcars and tank trucks are used for its transport by rail or road; they contain compressed hydrogen in the form of a pressurized gas. There are also tank trucks that transport liquefied hydrogen at -253°C. To make the world as climate-neutral as possible, these trucks and trains would have to be powered by renewable electricity or by a fuel produced with it. Another option would be to send the gas over long distances through pipelines, using comparatively little energy.

STATION 5 |

HYDROGEN FILLING STATION

Hydrogen fueling processes aren’t much of a change for today’s vehicle owners, although the pumps are operated a bit differently than the typical fuel dispenser. It should be noted that the tank in a fuel cell car or truck must be filled at high pressure. The hydrogen flows from the supply unit into the vehicle at about 700 bar. The fuel hose must be locked tightly to the coupling attached to the tank nozzle on the vehicle. Then the fuel hose is tightened pressure-tight automatically. An infrared interface takes the vehicle data that is important to the fueling process and transmits it to the pump. It takes up to four minutes to fill a car’s tank – just a bit longer than a comparable fill-up with gasoline or diesel. But the range with hydrogen-fueled vehicles is a bit less: between 400 and 500 kilometers.

STATION 6 |

FUEL CELL VEHICLES

Even if the fueling process resembles that of an internal combustion engine, it is an electric vehicle that the hydrogen is powering. Its fuel cell converts hydrogen into electric power that supplies the electric motor. In relation to its mass, hydrogen has immense energy density. The advantage: The use of hydrogen allows trucks and buses to cover the long distances they need to travel. But there is also a major disadvantage: Hydrogen is very light. In relation to volume, its energy density is quite low. This makes it necessary to compress it considerably. Even then, the tanks take up more space than conventional fuel tanks do. On the other hand, they need appreciably less space than today’s lithium ion batteries do.

STATION 7 |

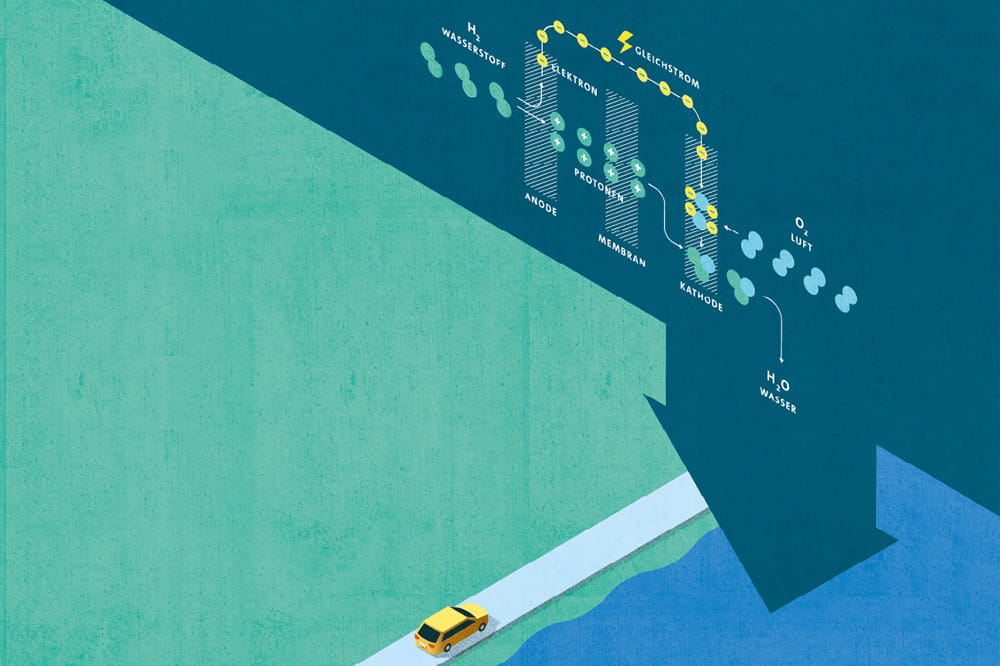

FUEL CELL

This is how fuel cells work: Positively charged hydrogen ions migrate within it from the anode to the cathode. On their way, they pass through a polymer electrolyte membrane. There they react with atmospheric oxygen, leaving water behind. During this process, a surplus of negatively charged hydrogen electrons is produced at the anode. If you connect these hydrogen electrons with the cathode across a separated power circuit, they will migrate there. That means electric current is flowing – but it is only about 50 percent of the current that was originally used to make hydrogen. This has led to a search for a more efficient solution. Freudenberg has developed a gas diffusion system that feeds gases as homogeneously as possible into the reaction process. The result is that only water vapor is emitted into the environment. And that closes the loop.

More news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new