Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

21.09.2021 | Story

Greenhouse Effect in Reverse

It still escapes from the smokestacks of industrial facilities and power plants and has a negative impact on the climate. But in just a few years, CO2 will be a much sought-after raw material that will replace fossil resources such as petroleum. The reason: CO2 contains carbon, the raw material for plastic.

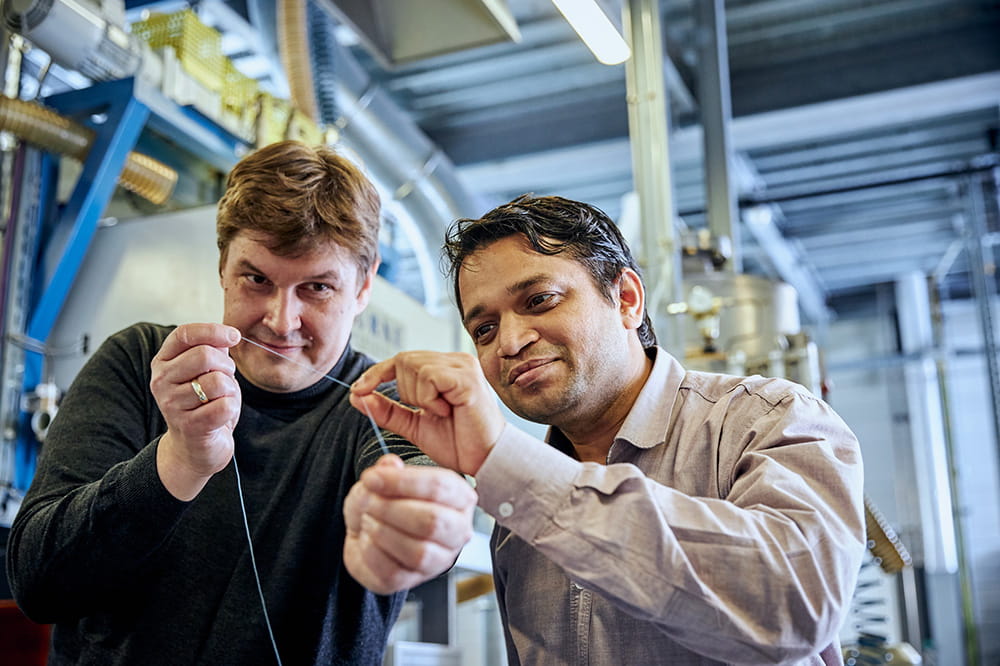

A small, elastic thread could lead to a revolution in the textile industry. That’s the message from Professor Pavan Manvi of the RWTH Aachen University and his fellow researcher Jochen Norwig of the Bayer subsidiary Covestro. In July 2019, they reported a breakthrough: In their lab in Krefeld-Uerdingen, Germany, they succeeded in producing a CO2-based elastic thread for the textile industry. If this thread can be produced commercially, it would be no mere niche development. Synthetic fibers would then no longer have to be produced from petroleum – it would be possible through the use of CO2, which could be obtained by scrubbing power plant exhaust gases or even by filtering it directly from the air – the greenhouse effect in reverse.

Covestro has already shown that the process can be carried out on a commercial scale. The Bayer subsidiary is working on industrial-scale production with the Institute for Textile Technology at RWTH Aachen and several textile manufacturers. “Stockings and medical textiles are due to be produced as a first step,” Covestro spokesman Sergio de Salve said.

"Cadyon" for a Good Sleep

The Bayer plant in Dormagen, not far from Leverkusen, is making a novel polyol with the trade name “Cardyon”. CO2 accounts for 20 percent of the material. The polyol is a main component in the production of soft polyurethane foam used in mattresses and other products. Covestro is already ready for the market in this area. For example, the Belgian company Recticel uses the material to make foam, and it markets the mattresses under the brand name Schlaraffia. Since 2016, Covestro has produced 5,000 tons of polyol per year. The company is also working on new applications for the foam in vehicle manufacturing, the production of seals and other fields.

Stockings and medical textiles are due to be produced.

Sergio de Salve, Site Communication, Covestro Deutschland AG

Even playing fields covered with artificial turf can be produced with CO2 as a raw material. In October 2018 in Krefeld, this type of field was installed at the Crefeld Hockey and Tennis Club (CHTC), a national-level hockey team and Europe Cup winner where the German national hockey team plays its home games. The special feature of its new deep-blue field surface is that a CO2-based plastic represents one-fifth of the material.

The 65-by-108- yard field is no anomaly. Polytan, which produces surfaces for sports facilities, is part of Bavarian-based Sport Group, the world’s largest maker of artificial turf and tracks. The company now plans to use the process to construct artificial turf worldwide. Other chemical companies such as BASF are doing research on plastics containing CO2. For example, BASF processes carbon dioxide into urea to produce artificial fertilizer. The company has also developed a process to use CO2 as the basis for the super-absorbers that soak up and encase urine in diapers.

Fuels from CO2

The notion of making fuels from CO2 is also on the brink of a breakthrough. These fuels are usually based on petroleum, but several research institutes and startups are in the process of developing pilot facilities that would use CO2. Two pioneering Swiss researchers, Christoph Gebald and Jan Wurzbacher, are in the forefront. They studied at ETH Zürich and formed Climeworks as a spinoff. It develops filtering systems that draw CO2 from ambient air. The CO2 can then be further processed using chemical reactions or introduced into the air inside of greenhouses as a growth enhancer. Since 2017, for example, a Climeworks facility in Hinwil, Switzerland, has drawn 900 tons of CO2 from the air. The gas is used in the production of fuels and in the beverage industry for carbonation.

One solar facility covering about 250 acres could produce more than 5,280 gallons of kerosene per day.

Climeworks now plans to team up with other companies such as Sunfire (Electrolysis), Ineratec (synthesis technology) and EDL Anlagenbau (the conversion of hydrocarbons into jet fuel) to build a facility to demonstrate the production of renewable aviation fuel on the grounds of the Rotterdam airport. This raises the prospect of climate-neutral aviation. Large ventilators would filter the CO2 from the airport’s ambient air. A solar facility provides the energy for the electrolysis system that produces a synthetic gas, from which synthetic hydrocarbons are extracted – the basis for the aviation fuel. In the fall of this year, Climeworks will present the airport with a feasibility study, and a new facility is expected to go into operation by 2021.

Energy From the Mirror

Working with their colleagues at the German Aerospace Center (DLR) in Cologne, researchers at the ETH Zürich are taking a different approach. In June, after managing to produce jet fuel from CO2 in the lab, they introduced a significantly larger “Sun to Liquid” research facility in Móstoles, Spain. It can produce a pint of jet fuel a day. “That is a breakthrough since the technology also works on a large scale,” said Prof. Christian Sattler, an expert in solar processes at the DLR. “We are going to use the results to develop the technology further.” It differs from the Climeworks and Sunfire technologies: The energy from the reaction is not produced with solar-generated electricity but with 169 mirrors that focus sunlight onto the reactor. The researchers estimate that a solar-based facility covering less than half a square mile could produce more than 5,000 U.S. gallons of jet fuel per day.

Sattler considers the production of fuel from CO2 to be a promising option for reducing the CO2 content of the atmosphere - and that could turn carbon dioxide into a windfall as raw material.

More news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new