Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

16.07.2019 | Story

Talking Seals

Seals do their jobs tirelessly, usually behind the scenes. Until now, machines mostly had to be dismantled to check the condition of these parts. That’s expected to change: At Freudenberg Sealing Technologies, a cross-disciplinary team is testing seals that identify and communicate their level of wear. They are based on a novel material that functions as a sensor.

It’s time for maintenance at a beverage bottling facility. Different components of the equipment are opened up, and the seals on tubes, pumps and valves are checked. If they are worn out, they have to be replaced. But if they are still intact, the check itself – a common yet expensive process – is superfluous. What would happen if the seals themselves could autonomously measure and transmit information about the level of their wear? And determine the exact point – no sooner and no later – when little of the seal lip is left and the seal has to be replaced?

Seals Identifying Wear Automatically

A cross-disciplinary research team at Freudenberg Sealing Technologies addressed this question. Working with a customer from the process industry, experts developed a seal that measures its own wear. The key benefit: The maintenance of processing equipment – filling equipment in this case – could be performed based on actual need. Moreover, the service staff would have the opportunity to time the maintenance perfectly for the equipment’s operating schedule. Unplanned stoppages due to leaks would become a thing of the past.

Electrically Conductive Rubber

Seals are mostly made of elastomers that, in their pure form, are unable to process signals. To arm them with intelligence, it is possible to integrate a sensor or a microchip into a seal. But since the integrated element is a foreign body, it could impair the seal’s functioning. “So we focused our attention on approaches where the intelligence comes from the material itself,” Dr. Boris Traber, who is in charge of the development of new materials at Freudenberg Sealing Technologies. The researchers equipped a sealing material with special fillers to make the elastomer electrically conductive. At the same time, the material had to have qualities that are just as functional as those of a conventional seal. And, since the seals come into direct contact with the food during the filling process, they can only contain components that are on the positive list approved by the EU and the FDA.

Electric Signal Points to Leakage

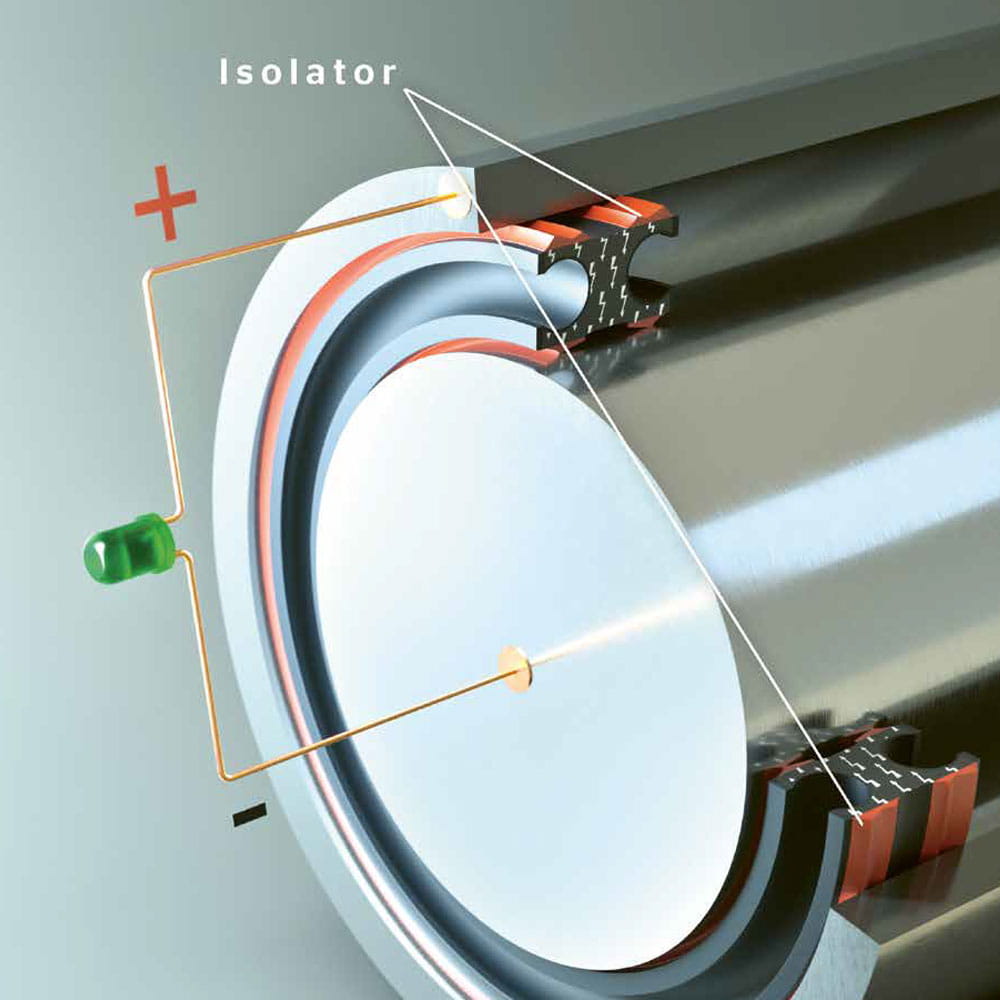

The design and measurement principles that the seal uses to convey the level of its wear are just as important as its material mixture. In this particular application, an external transducer sends an electric signal over a lead to the seal. This creates voltage between the electrically conductive portion of the seal and the external housing, and the seal lip in-between insulates the two surfaces from one another. The greater the wear of the seal, the less it can effectively insulate the two electrodes from one another. As a result, the electrical capacity changes. If you measure the change, you can draw conclusions about the condition of the seal lip.

Development to Production Readiness

This smart seal is now due to be developed to production-readiness for specific applications. The effort involves material developers, product developers, process specialists and sensor experts who are working hand-in-hand with colleagues from operating areas, the Freudenberg Sealing Technologies sales organization and the customer’s application experts. Of course, it would take a good many experts to actually make seals that were talkative. But it would be possible – that much is clear.

In the May edition of our customer magazine ESSENTIAL, we explain how smart seals are developed and used. Read more about them here.

More news on the subject Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new