Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

04.04.2017 | Story

Robots with a Fine Sensitivity

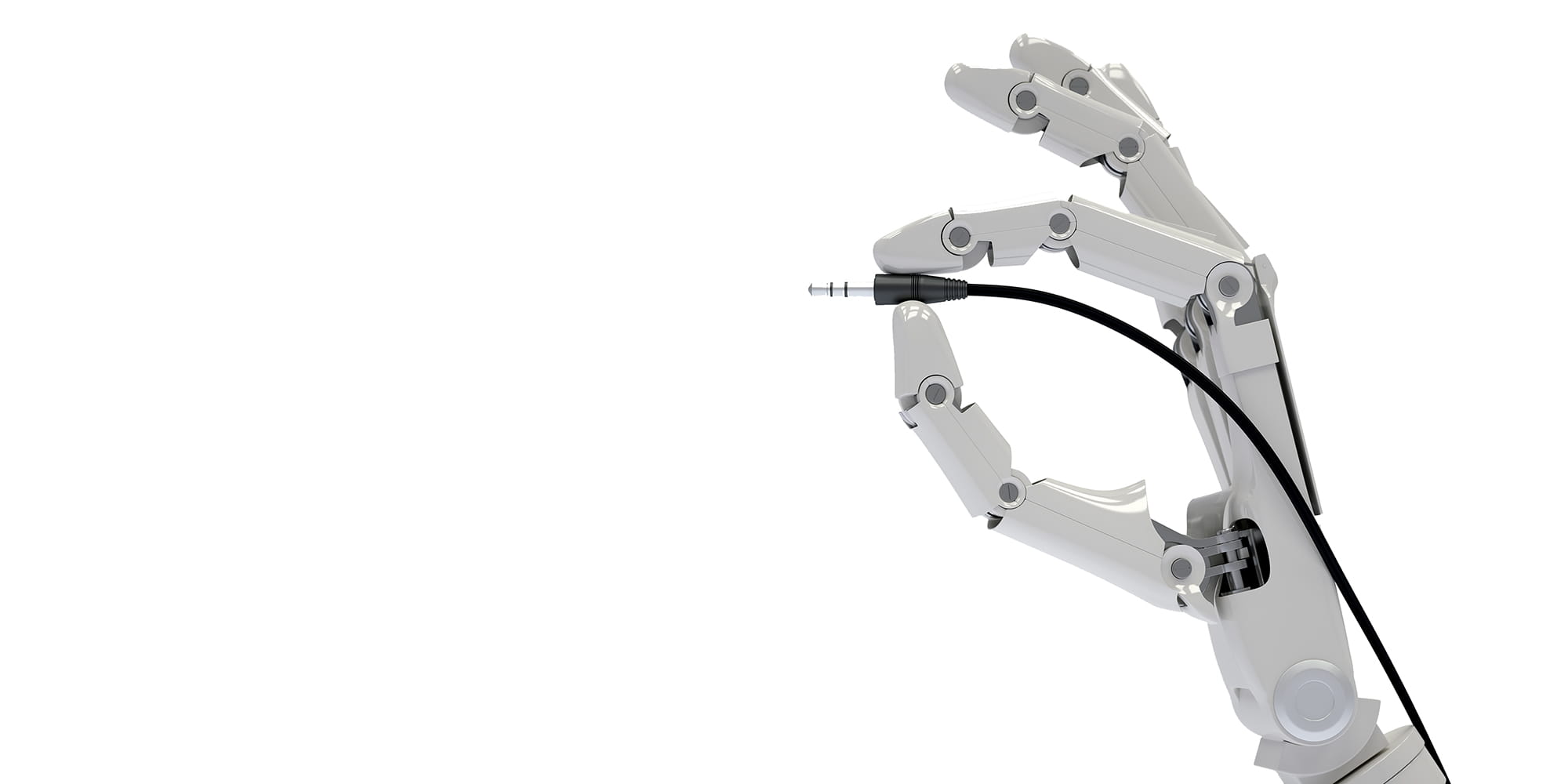

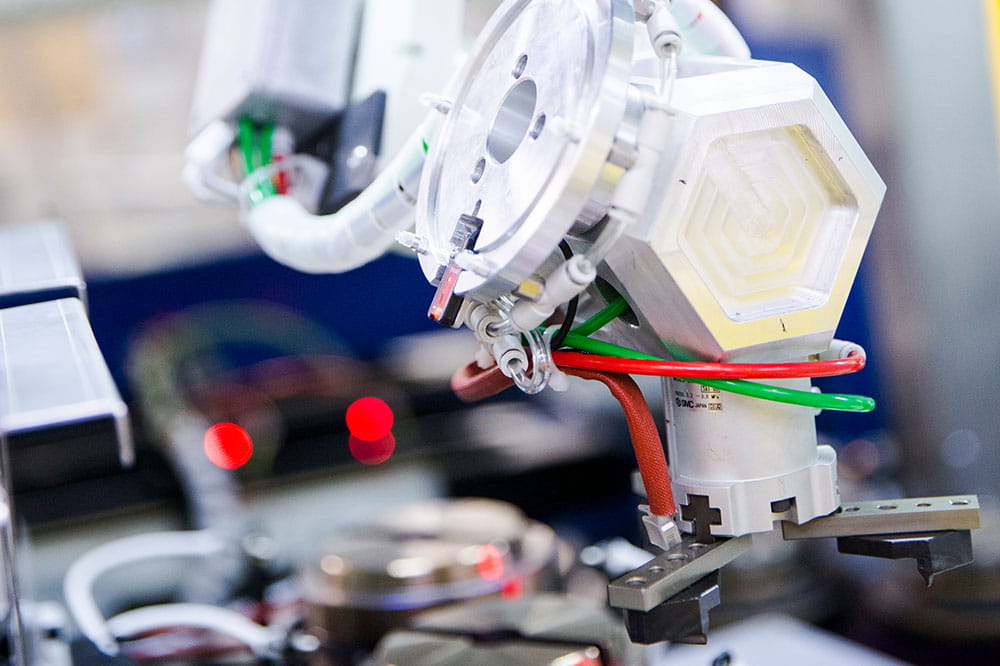

An arm swings backward before bringing a nail up to a balloon. But at the precise moment when the tip of the nail would strike its surface, the arm stops abruptly. The balloon doesn’t burst. The body control is impressive – all the more because this is the arm of a robot.

Industrial robots make many production processes easier. Experts believe it will impossible to get around the use of cobots.

What is already a sensation on a small scale is expected to revolutionize work on the shop floor in the very near future. Collaborating robots – so-called cobots – with fine sensor systems and the capacity to learn – are on the advance. They are designed to support manufacturing workers and have the ability to react to external influences. Instead of the threatening scenario of job destruction that robots often bring to mind, helpful cobots could emerge as the robots of the future, assisting workers instead of eliminating their work.

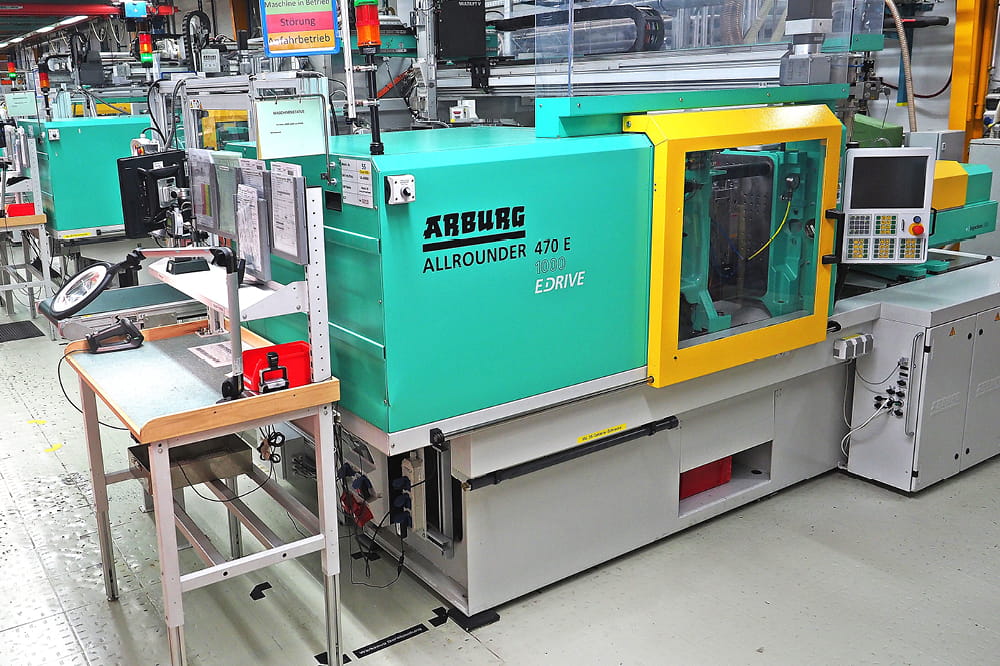

Until now, industrial robots have been primarily geared to a function. Their work is as monotonous as it is precise. They take over the employee’s arduous work processes. After hours, weeks and months, they continue to put the welding joint exactly where it is supposed to be. In other words, industrial robots are functionally oriented. They were responsible for an entirely new dynamic in manufacturing that made higher production output possible. The classic articulated-arm robot is still the model in most demand.

Industrial robots make many production processes easier. Experts believe it will impossible to get around the use of cobots.

Going from nearby to together

Although people and machines have now been involved with one another in production processes for decades, there has not been cooperation in the literal sense to this point. Robots were programmed and focused on their assigned tasks, without particularly responding to external influences. That is expected to change with cobots. At the Hannover Messe 2016 and at CeBIT 2017, manufacturers attracted attention with robots that could learn and perform sensitive tasks. The machines are already executing almost delicate tasks. They could lift small objects and set them down, turn screws, and even carry out precise plug insertions. As the demonstration with the nail in the balloon shows, the new robots are even capable of reacting to resistance. This is important when the work involves people and machines actually working hand-in-hand in the future. For example, thanks to torque sensors in the joints of a robotic arm, the risk of injury to the robot’s human colleagues declines significantly. But the new cobots are supposed to be more than just aids. They are expected to learn new activities at the same time; the workers guide the robots’ hands so they can internalize an unfamiliar work step.

Industrial robots still sit behind glass or grates. In the future, they are expected to work side-by-side with the operator.

Affordable and Easy to Operate

One factor on particular could immediately expand the use of cobots: their low prices. There is already a company that plans to bring out its latest model for less than 10,000 euros. That price will even have fairly small companies paying attention. Multifaceted robots are also expected to be extremely easy to control. Programming knowledge is not required. Preprogrammed movements are handled with apps, and even laypersons would be able to operate them intuitively.

Lacking the capacity to move considerable loads by themselves, these highly sensitive robots are still lightweights. That disqualifies them for many production processes, but even this challenge is likely to be overcome at some point. Here robots could help people work longer in what had been physically demanding fields; thanks to cobots, experienced – and therefore valuable – employees would stay in their jobs longer than they do now. The sensitive robot would become a friend and helper in the workplace.

More news on the subject Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new